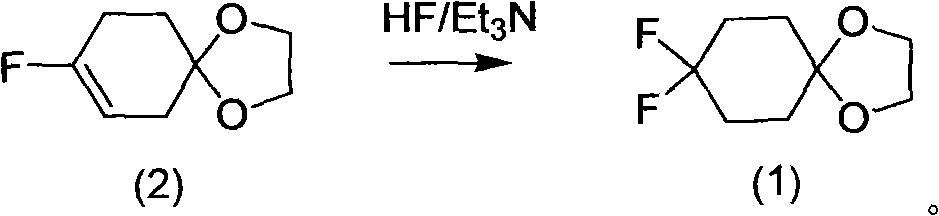

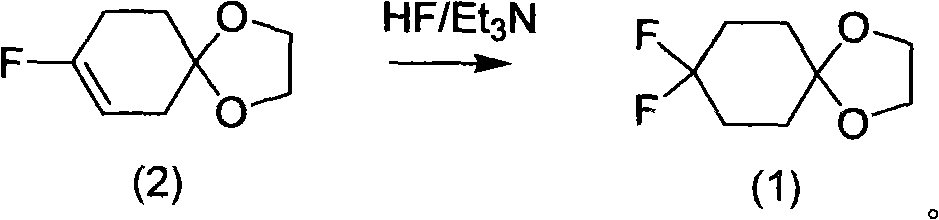

Method for preparing 4,4-difluoro cyclohexanone diethyl acetal

A technology of difluorocyclohexanone ethylene diketal and cyclohexenone ethylene diketal, which is applied in the field of preparation 4, can solve problems such as uneconomical application and waste, and achieve production cost saving, simple process, and cheap and easy raw materials. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Under the protection of nitrogen, put 2 mol of 4-fluoro-3-cyclohexenone ethylene diketal (2) into the reaction bottle, add 2 mol of HF dropwise, after the dropwise addition, cool down to -30°C, add 0.2 mol of triethylamine dropwise , the dropwise addition time is 2h, react for 30h after the dropwise addition is completed, then pour the reaction solution into water, extract the water phase with dichloromethane after layering, spin dry and recrystallize, and prepare 4,4-difluorocyclohexane Ketone ethylene diketal 1.6mol, the yield is 80%.

Embodiment 2

[0016] Under the protection of nitrogen, put 1 mol of 4-fluoro-3-cyclohexenone ethylene diketal (2) into the reaction bottle, add 1 mol of HF dropwise, after the dropwise addition, cool down to -20°C, add 0.1 mol of triethylamine dropwise , the dropwise addition time is 2h, react for 36h after the dropwise addition is completed, then pour the reaction liquid into water, extract the water phase with dichloromethane after layering, spin dry and recrystallize, and prepare 4,4-difluorocyclohexane Ketone ethylene diketal (1) 0.7, the yield is 70%.

Embodiment 3

[0018] Under the protection of nitrogen, put 2 mol of 4-fluoro-3-cyclohexenone ethylene diketal (2) into the reaction bottle, add 2 mol of HF dropwise, after the dropwise addition, cool down to -40°C, add 0.2 mol of triethylamine dropwise , the dropping time is 2 hours, and the reaction is 24 hours after the dropping is completed. Subsequently, the reaction solution is poured into water, and the water phase is extracted with dichloromethane after layering. After spinning to dryness and recrystallization, the 4,4-difluorocyclic Hexanone ethylene diketal (1) 1.7mol, the yield is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com