Solid-phase-free multi-functional well completion working solution

A multi-functional, working fluid technology, applied in the direction of wellbore/well components, earthwork drilling, drilling composition, etc., can solve problems such as single function and inability to meet the multifunctional requirements of well completion working fluid, and achieve Avoid the effects of early corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation method of multi-functional well completion working fluid:

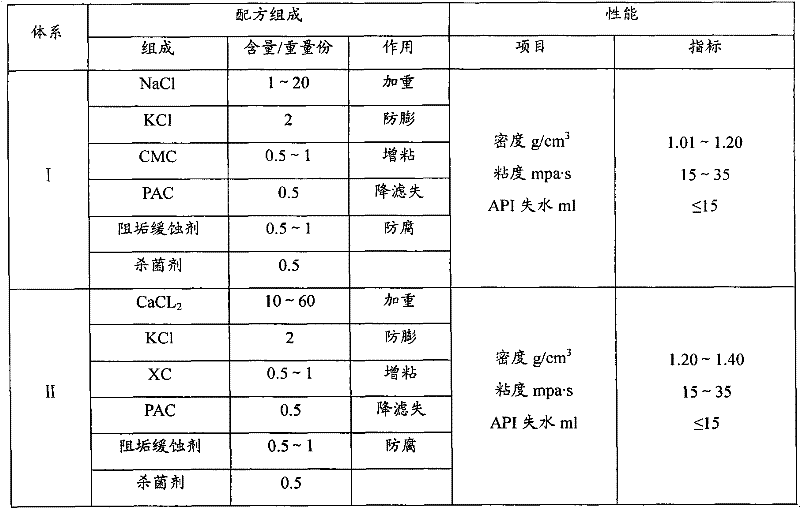

[0023] Weigh 1-60 tons of inorganic salt, 0.2-20 tons of anti-swelling agent, 0.2-5 tons of viscosifier, 0.2-5 tons of fluid loss reducer, 0.2-2 tons of scale and corrosion inhibitor, and 0.2 tons of fungicide according to the raw material formula. -5 tons;

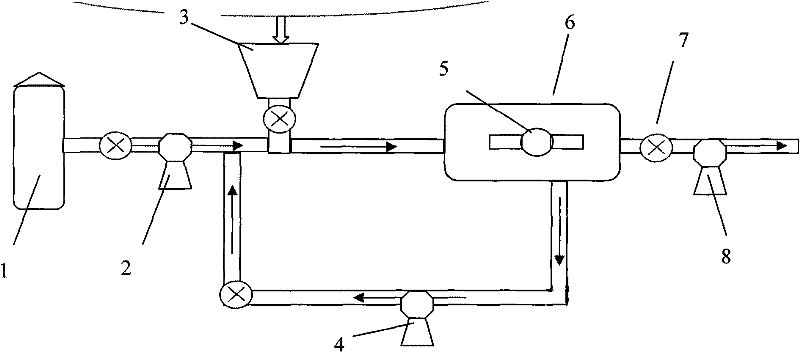

[0024] refer to figure 1 , pump clean water from clean water tank 1 for 100-300m 3 After filtering through the filter, pump it into the mud tank 6 through the pump A2. While pumping clean water, add 1-60 tons of inorganic salt, 0.2-20 tons of anti-swelling agent, and thickening agent through the dosing funnel 3 in sequence. 0.2-5 tons of agent, 0.2-5 tons of fluid loss reducer, 0.2-2 tons of scale and corrosion inhibitor, 0.2-5 tons of fungicide, the agitator 5 in the mud tank 6 pairs of clean water and medicines added by the dosing funnel 3 Fully stir and circulate through the pump B4 at the same time. After circulating and stirring for ...

Embodiment 2

[0058] Well Kuidong 103 was completed in August 2006. During the first sand control, the packer slips were not seated, and the sand control string fell after losing hands, resulting in objects falling at the bottom of the well. In May 2007, Well Kuidong 103 was overhauled, and the operation period was 38 days.

[0059] Inject clean water 150m into the mud tank 3 , Add 6.5 tons of NaCl and 3.2 tons of KCl under stirring. Under high-speed stirring, add 0.8 tons of PAC, 0.8 tons of CMC, 12470.8 tons of fungicides, and 0.8 tons of scale and corrosion inhibitors sequentially through the dosing funnel. After stirring for 4 hours, it is used in multiple processes such as salvage, sand washing, and perforation.

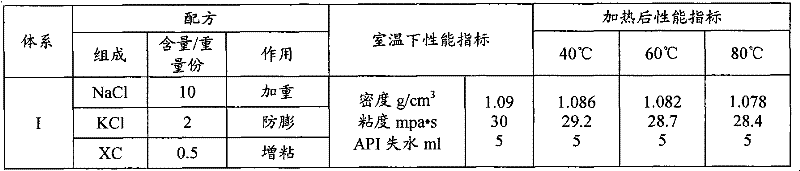

[0060] During the process of plug drilling and sand flushing, the working fluid stays in the wellbore for more than 72 hours for many times. When it circulates out of the wellbore, its temperature is measured at 36°C and its density remains at 1.06g / cm 3 , Viscosity 28mpa·...

Embodiment 3

[0062] Well Kuidong 1-H1 is the first horizontal well in the Kuidong block in the Liaohe Sea, and was drilled in 2007. The formation pressure of this well is relatively high, and the screen completion method is adopted, and there is a large amount of high-viscosity oil layer protection agent in the horizontal section of the screen. Well completion construction was carried out in August 2008, and the new solid-free multifunctional well completion working fluid showed good performance during the well completion process. When starting to replace the mud, it encounters high-pressure gas in the well, accompanied by ground seepage. Prepare high-density, high-performance working fluid, while killing wells and spraying at the same time. The spraying process was controlled.

[0063] The entire well completion construction, the design use density is 1.20g / cm 3 Working fluid 280m 3 . It is used in various links such as replacing drilling mud, killing wells, and perforating. After r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com