Copper alloy

A copper alloy, quality technology, applied in the direction of metal pattern materials, conductive materials, conductive materials, etc., can solve the problem of not having layered boundaries, and achieve excellent bending workability, good electrical conductivity, bending workability and resistance to stress relaxation. Excellent effect

Inactive Publication Date: 2012-07-04

KOBE STEEL LTD

View PDF9 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The copper alloy sheet disclosed in Patent Document 1 is a Corson alloy containing 2.0 to 6.0% by mass of Ni, and the average grain size of a Corson alloy of Si in the range of 4 to 5 in terms of the mass ratio of Ni / Si is set to 10 μm. Below, and according to the measurement results of the SEM-EBSP method, there is an aggregate structure with a ratio of Cube orientation {001} of 50% or more, and there is no structure observed by observation of the structure with a 300-magnification optical microscope layered boundary

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

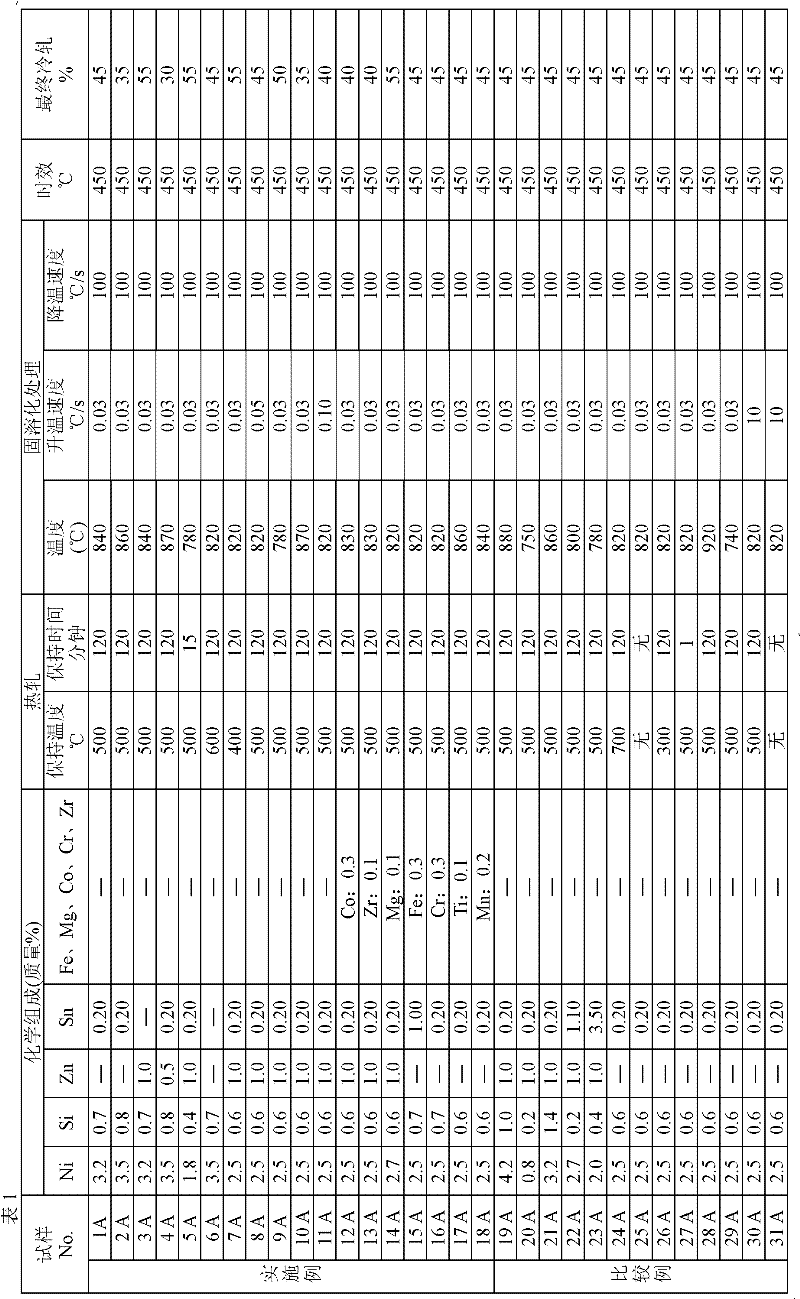

[0169] Hereinafter, the present invention will be described in more detail by citing the examples, but the present invention is certainly not limited by the following examples, and can also be implemented with appropriate changes within the scope suitable for the gist of the present invention, which are all included in this document. The technical scope of the invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

A copper alloy containing Ni: 1.5% - 3.6% and Si: 0.3% - 1.0% in terms of mass percent with the remainder consisting of copper and unavoidable impurities, wherein: the average crystal grain size of the crystal grains in the copper alloy is 5 to 30 [mu]m; the area ratio of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 3%; and the ratio of the area of cube orientation grains to the area of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 50%.

Description

technical field [0001] The present invention relates to a copper alloy having good electrical conductivity, high strength, excellent bending workability, and excellent stress relaxation resistance, and in particular to a connector and lead frame suitable for constituting electric and electronic parts Copper alloys for electrical and electronic parts such as relays, switches, etc. Background technique [0002] Copper alloy materials used for electrical and electronic components such as connectors, lead frames, relays, switches, etc., are required to have good electrical conductivity in order to suppress Joule heat generated by electrical and electronic components, and to withstand electrical and electronic components as much as possible. High strength of stress imparted during assembly or work. In addition, electric and electronic parts are generally formed by bending, and materials for the bent electric and electronic parts are also required to have excellent bending workab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C9/06C22C9/02C22C9/04C22C9/00C22C9/05

CPCH01B1/026C22C1/02C22F1/08C22C9/06H05K1/09C22C9/00C22C9/02C22C9/04

Inventor 宍户久郎桂进也有贺康博松本克史

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com