Chemical copper-plating solution and chemical copper-plating method

A technology of electroless copper plating and copper salt, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of difficult to obtain and thick copper plating, and achieve the effect of increasing the maximum thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

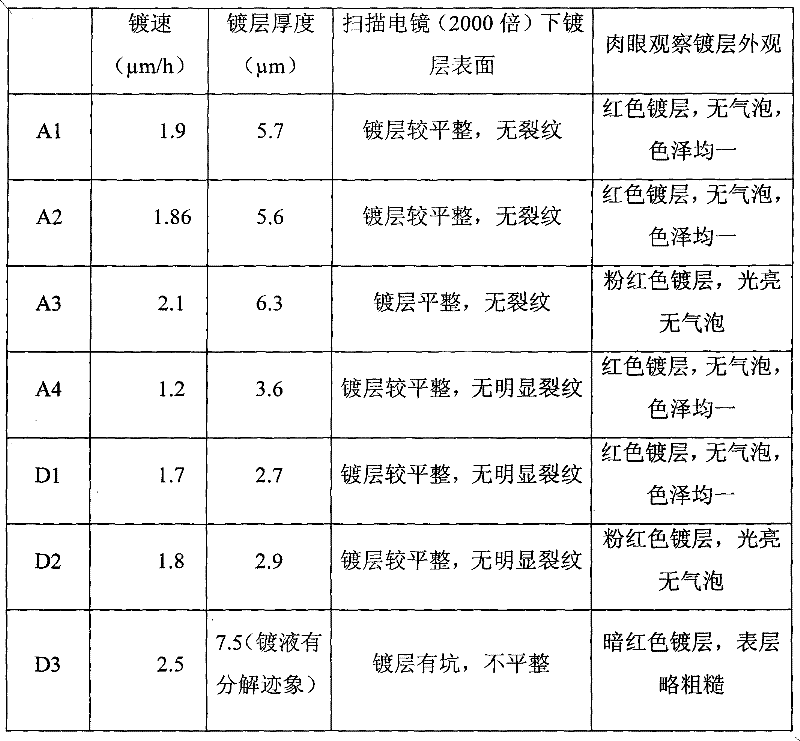

Examples

Embodiment 1

[0036] The specific content of electroless copper plating solution A1 is as follows:

[0037] Copper sulfate pentahydrate 7g / L

[0038] Triethanolamine 12g / L

[0039] NaOH 8g / L

[0040] 2-aminopyridine 0.002g / L

[0041]Sodium citrate 10g / L

[0042] Nickel sulfate 0.6g / L

[0043] Sodium hypophosphite 32g / L

[0044] 4-cyanopyridine 0.003g / L.

Embodiment 2

[0046] The difference with Example 1 is that the electroless copper plating solution also contains stabilizer potassium ferrocyanide, complexing agent ethylenediamine, and the specific content is

[0047] Potassium ferrocyanide 0.005g / L

[0048] Ethylenediamine 1.5g / L,

[0049] Obtain electroless copper plating solution A2.

Embodiment 3

[0051] The difference with embodiment 2 is that surfactant sodium dodecylbenzenesulfonate is also contained in the electroless copper plating solution, accelerator ammonium chloride, and concrete content is:

[0052] Sodium dodecylbenzenesulfonate 0.003g / L,

[0053] Ammonium chloride 1g / L,

[0054] Obtain electroless copper plating solution A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com