Pulverized coal activator and coking coal prepared from same

An activator and pulverized coal technology, which is applied in the field of pulverized coal activator and coking coal, can solve the problems of unfavorable coke quality, increased coal water content, high sulfur content, etc., and achieve low comprehensive cost, increased fluidity and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

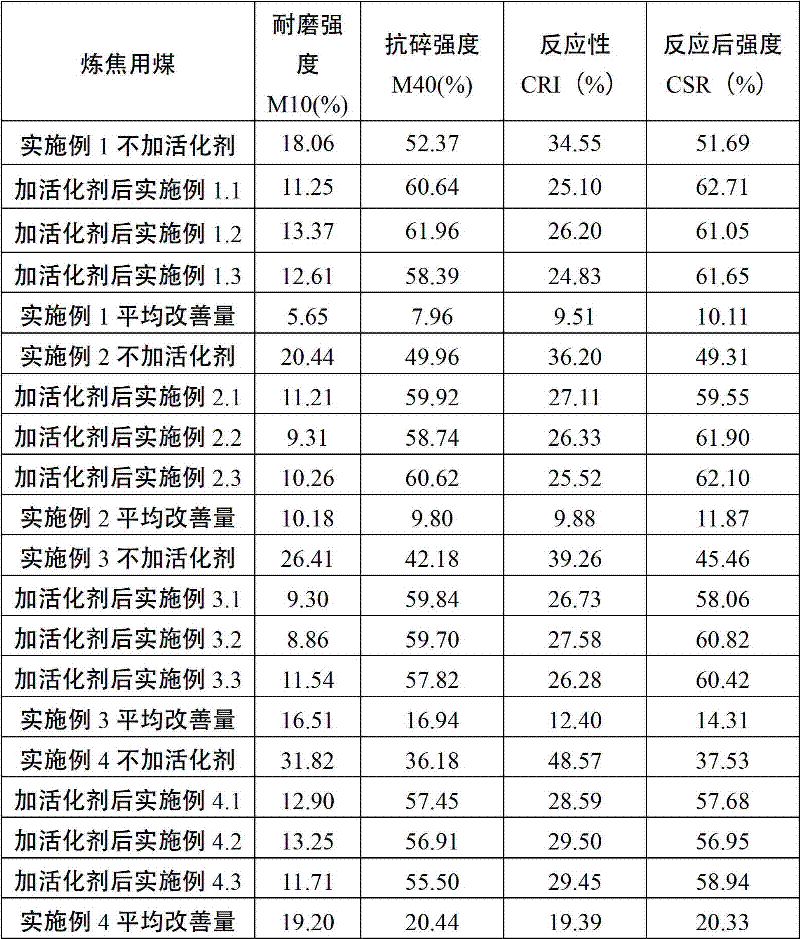

Embodiment 1

[0037] To prepare coal powder activator, the weight percentage of each component is: 3% resin clay, 6% glucose, 5% cobalt molybdate, 1% cholesteryl benzoate, 2% boric anhydride, 3% Clay, 13% titanium dioxide, 16% sodium stearate, 2% ferric chloride, 9% clay, 3% anhydrous borax, 13% modified starch, 24% tar residue.

[0038] Then the pulverized coal activator is mixed with mixed coal, wherein the weight percentage of the pulverized coal activator is 1%; the non-coking coal is lean coal, and the weight percentage is 20%; the coking coal is 79% by weight, and the ratio is : 25% coking coal, 20% fat coal, 15% gas coal, 40% lean coal. All kinds of coal are domestic coal.

Embodiment 2

[0040] To prepare coal powder activator, the weight percentage of each component is: 12% resin clay, 23% glucose, 3% cobalt molybdate, 18% cholesteryl benzoate, 28% boric anhydride, 2% Clay, 3% titanium dioxide, 2% sodium stearate, 1% ferric chloride, 2% clay, 3% anhydrous borax, 1% modified starch, 2% tar residue.

[0041] Then the pulverized coal activator is mixed with mixed coal, wherein the weight percentage of the pulverized coal activator is 2%; the non-coking coal is white coal, and the weight percentage is 50%; the coking coal is 48% by weight, and the ratio is : 25% coking coal, 20% fat coal, 15% gas coal, 40% lean coal. All kinds of coal are domestic coal.

Embodiment 3

[0043] To prepare coal powder activator, the weight percentage of each component is: 5% resin clay, 10% glucose, 4% cobalt molybdate, 5% cholesteryl benzoate, 18% boric anhydride, 8% Clay, 10% titanium dioxide, 4% sodium stearate, 2% ferric chloride, 4% clay, 18% anhydrous borax, 3% modified starch, 9% tar residue.

[0044] Then the pulverized coal activator is mixed with the blended coal, wherein the weight percentage of the pulverized coal activator is 4%; the non-coking coal is non-stick coal, and the weight percentage is 75%; the coking blended coal is 21% by weight, and the ratio is It is: 25% coking coal, 20% fat coal, 15% gas coal, and 40% lean coal. All kinds of coal are domestic coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com