AM60 magnesium alloy surface heavy-layer treatment method

A treatment method and surface treatment technology, applied in the field of AM60 magnesium alloy surface thick layer treatment, can solve the problems of no protection, loose protective layer, pilling, etc., to improve sintering effect, increase the maximum thickness, and enhance sintering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

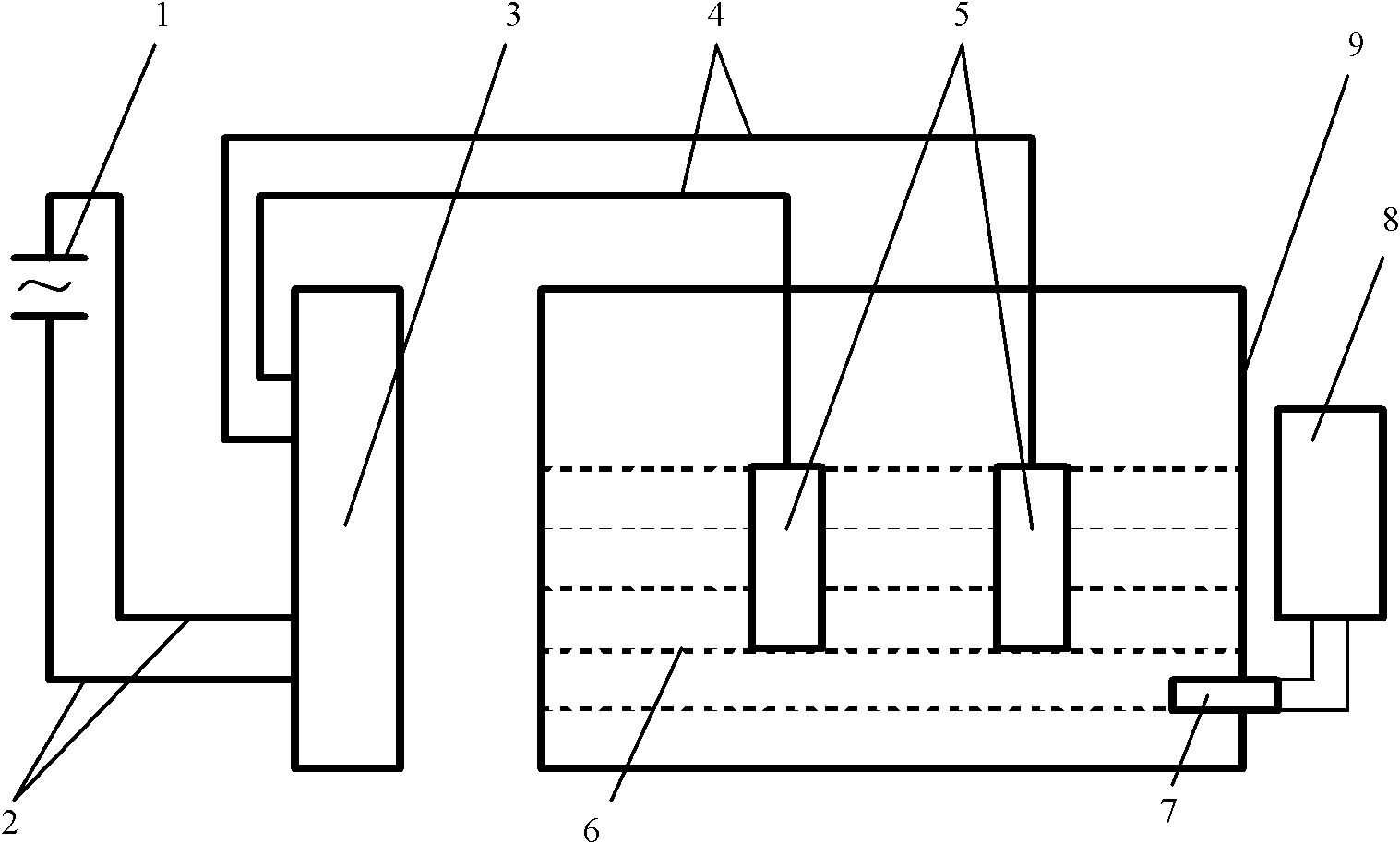

Method used

Image

Examples

Embodiment approach 1

[0016] Embodiment 1, under the conditions of potassium fluoride concentration of 406g / L, potassium hydroxide concentration of 188g / L, power frequency AC voltage of 114V, and oxygen injection rate of 0.01L / s per liter of treatment liquid, AC plasma micro After 119 seconds of arc oxidation surface treatment, a dense and uniform thick protective layer with a thickness of 55 μm can be formed on the surface of AM60 magnesium alloy workpiece.

Embodiment approach 2

[0017] Embodiment 2, under the conditions of potassium fluoride concentration of 406g / L, potassium hydroxide concentration of 188g / L, power frequency AC voltage of 116V, and oxygen injection rate of 0.01L / s per liter of treatment liquid, AC plasma micro After 119 seconds of arc oxidation surface treatment, a 58 μm thick and uniform protective layer can be formed on the surface of AM60 magnesium alloy workpiece.

Embodiment approach 3

[0018] Embodiment 3, under the conditions of potassium fluoride concentration of 408g / L, potassium hydroxide concentration of 188g / L, power frequency AC voltage of 114V, and oxygen injection rate of 0.016L / s per liter of treatment liquid, AC plasma micro After 149 seconds of arc oxidation surface treatment, a dense and uniform thick protective layer with a thickness of 62 μm can be formed on the surface of AM60 magnesium alloy workpiece.

[0019] Embodiment 4, under the condition that the concentration of potassium fluoride is 408g / L, the concentration of potassium hydroxide is 190g / L, the power frequency AC voltage is 116V, and the injection rate of oxygen per liter of treatment liquid is 0.016L / s, the AC plasma micro After 149 seconds of arc oxidation surface treatment, a dense and uniform protective layer with a thickness of 65 μm can be formed on the surface of AM60 magnesium alloy workpiece.

[0020] Embodiment 5, under the conditions of potassium fluoride concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com