Vacuumizing-electroosmosis-stacking combined soft-foundation consolidating system and method

A combined stacking and electroosmosis technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of tearing vacuum film, no compaction of soil, and high cost, improving uniformity and maintaining integrity performance, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

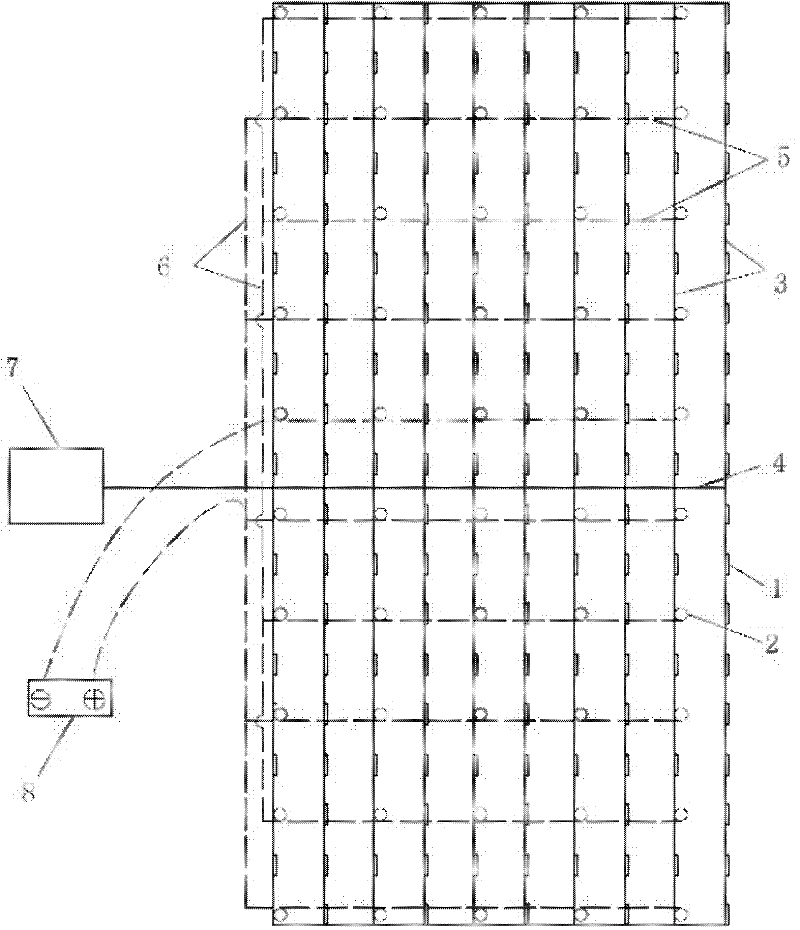

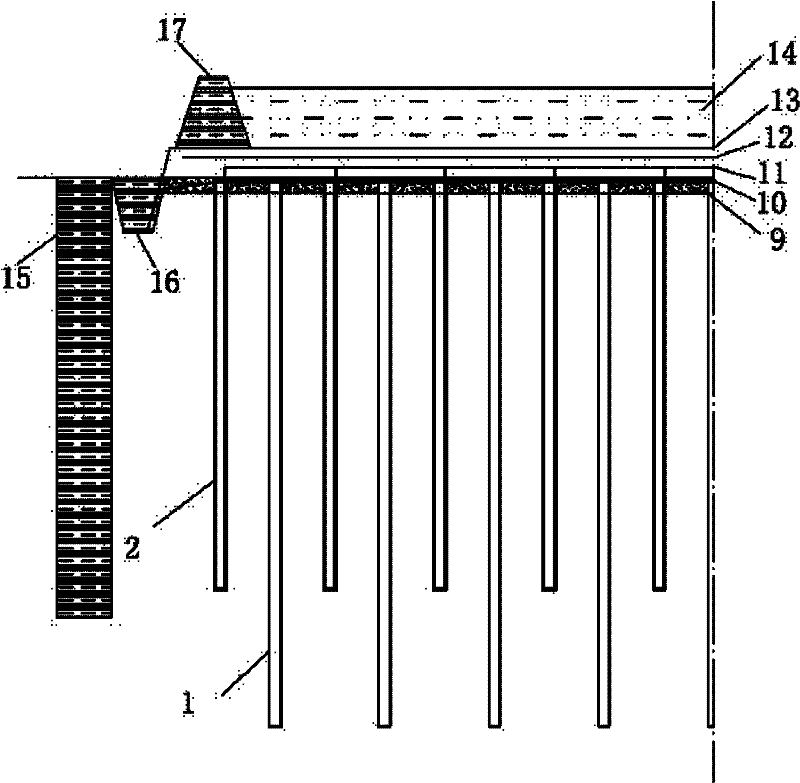

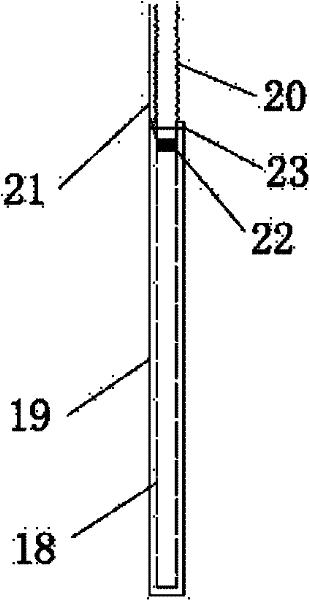

[0035] Such as figure 1 , 2 As shown in and 3, a vacuum-electroosmosis-surcharge combined reinforcement system for soft foundations consists of retractable drainage electrodes (2), conductive lines (11), DC power supply (8), horizontal drainage pipelines (10) and Vacuum pump (7) etc. are formed.

[0036] A vacuum-electroosmosis-surcharge combined method for strengthening soft foundations can be realized by adopting the following technical steps:

[0037] (1) Clean up the site and lay a 30cm-50cm thick sand cushion (9).

[0038] (2) If there is a sand layer in the foundation, a sealing wall (15) should be installed to prevent air leakage. Use a mixing pile machine to drive the mud mixing piles, and the double rows of mixing piles are overlapped to form a clay sealing wall (15). The diameter of a single pile is 60cm-70cm, and the overlap is 10cm-15cm. The pile length must exceed the depth of the underground sand layer by more than 1m.

[0039] (3) Make the drainage electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com