LED (light-emitting diode) bulb lamp

A technology of LED bulb lamps and lamp cups, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve problems such as cumbersome processing technology, shorten service life, and early light decay, and achieve low manufacturing costs, Prevention of wrong assembly, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the LED bulb lamp of the present invention will be described below with reference to the accompanying drawings.

[0037] Embodiments of the present invention are described with reference to the accompanying drawings, which illustrate specific embodiments in which the present invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", "side", etc., are only referring to the directions of the attached drawings . These directional terms are used to illustrate and understand the present invention, but not to limit the present invention. In the following embodiments, the same parts are denoted by the same symbols in different drawings.

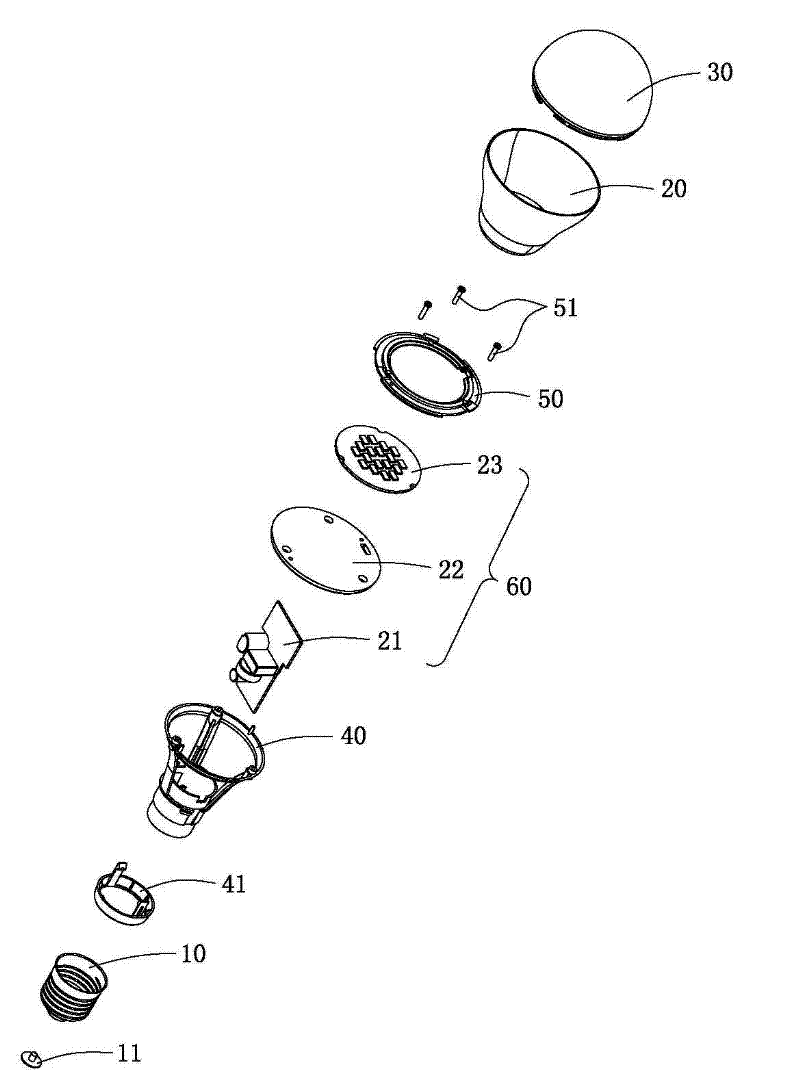

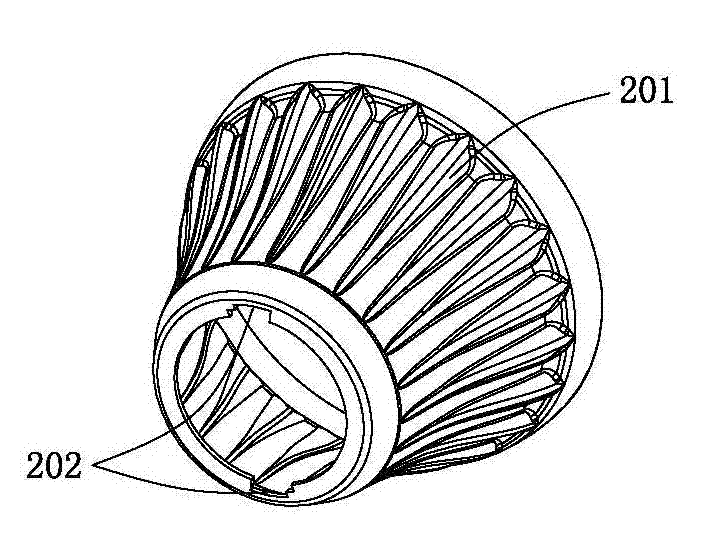

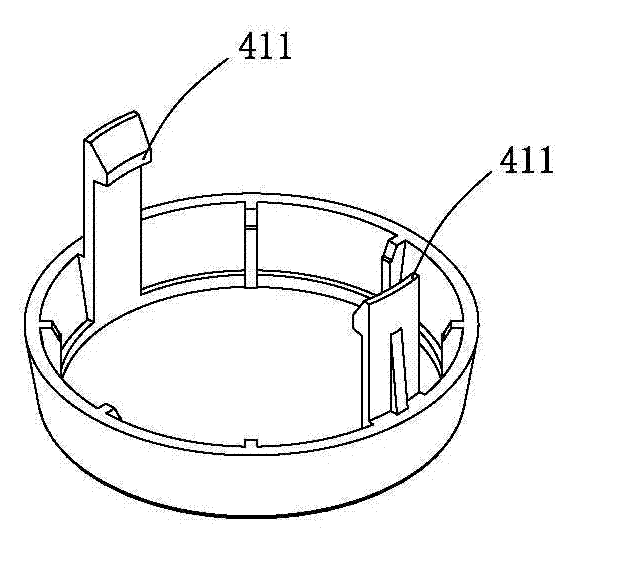

[0038] refer to figure 1 . An LED bulb lamp includes a base 10 and a lampshade 30 installed at both ends of a lamp cup 20 . The lamp cup 20 has a circuit board 60 inside, and the circuit board 60 includes a power board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com