Method for absorbing and recycling yellow phosphorus burning heat by using heat-conducting oil

A heat-conducting oil and yellow phosphorus technology, which is used in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of phosphorus chemical industry that have not been used before, avoid hidden dangers of overpressure, reduce operating pressure and Safety requirements, reducing the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

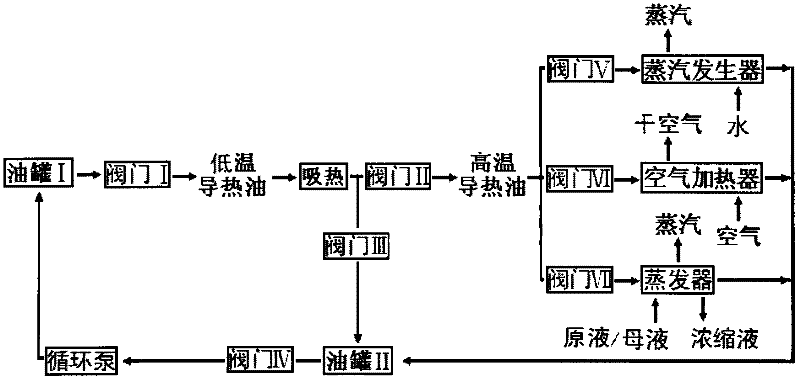

[0022] Embodiment one: the concentration of phosphate mother liquor and the drying of phosphate

[0023] Add the alkylbiphenyl type heat transfer oil into the high-level low-temperature heat-conducting oil tank I, and then open the valve I of the high-level low-temperature heat-conducting oil tank I, the valve III of the jacket outlet of the yellow phosphorus combustion furnace, and the valve IV of the oil tank II, Close the valve II of the jacket outlet of the yellow phosphorus combustion furnace, low-temperature heat transfer oil flows into the jacket of the yellow phosphorus combustion furnace to absorb heat, and control the flow rate of valve III at the outlet of the yellow phosphorus combustion furnace jacket to control the temperature of the heat transfer oil at the outlet of the yellow phosphorus combustion furnace jacket At 200°C, start the circulating oil pump to pump the low-temperature heat transfer oil from the oil tank II into the high-level low-temperature heat tr...

Embodiment 2

[0024] Embodiment two: the concentration of phosphate mother liquor

[0025] Add the alkylbenzene type heat transfer oil into the high-level low-temperature heat-conducting oil tank I, and then open and close the valve I of the high-level low-temperature heat-conducting oil tank I, the valve III of the jacket outlet of the yellow phosphorus combustion furnace, and the valve IV of the oil tank II The valve II at the outlet of the jacket of the yellow phosphorus combustion furnace, the low-temperature heat transfer oil flows into the jacket of the yellow phosphorus combustion furnace to absorb heat, and the flow rate of the valve III at the outlet of the jacket of the yellow phosphorus combustion furnace is controlled to control the temperature of the heat transfer oil at the outlet of the jacket of the yellow phosphorus combustion furnace 180 ℃, start the circulating oil pump to pump the low-temperature heat-conducting oil from the oil tank II to the high-level low-temperature h...

Embodiment 3

[0026] Embodiment three: the concentration of phosphate mother liquor, the drying of phosphate and preparation steam

[0027]Add the biphenyl / biphenyl ether low-melting mixture type heat transfer oil into the high-level low-temperature heat-conducting oil tank I, and then put the valve I of the high-level low-temperature heat-conducting oil tank I, the valve III of the jacket outlet of the yellow phosphorus combustion furnace, and the oil tank II The valve IV of the yellow phosphorus combustion furnace jacket is opened, and the valve II of the outlet of the yellow phosphorus combustion furnace jacket is closed. The low-temperature heat transfer oil flows into the yellow phosphorus combustion furnace jacket to absorb heat, and the flow rate of the valve III at the outlet of the yellow phosphorus combustion furnace jacket is controlled to control the yellow phosphorus combustion furnace jacket. The temperature of the heat transfer oil at the outlet is 360°C. Start the circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com