Method for testing stability of cathode slurry and preparation method of cathode slurry

A negative electrode slurry and testing method technology, applied in the preparation of test samples, measuring devices, particle size analysis, etc., can solve problems that are not conducive to the stability of the slurry, and achieve the effects of strong practicability, accurate results, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

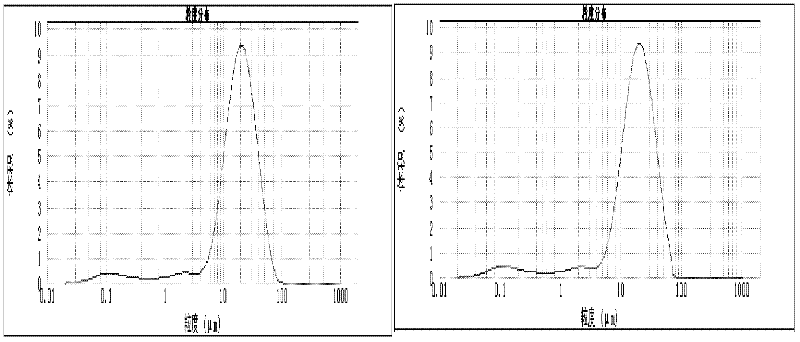

[0023] Take graphite I (D50:20um), CMC, SBR, Sp, oxalic acid and deionized water. According to mass percentage: 160:4:4:3:400, use XFZH planetary dispersion stirring vacuum mixer to stir for 10 hours. A negative electrode slurry with uniform dispersion and good stability is obtained. Take 200ml of this negative electrode slurry and place it in a colorless and transparent glass separatory funnel. Measure the particle size distribution of the upper and lower slurry particles when the slurry is placed for 0h, 2h, 4h, 6h, 8h, 10h, 12h, 16h, 20h, 24h, and calculate the particle size ratio of the upper and lower layers, and draw the upper and lower layers The relationship between particle size ratio and time is a1. When testing, take the slurry 1cm away from the surface and bottom of the suspension for testing.

[0024] The laser particle size analyzer can use the Malvern MS2000 laser particle size analyzer. The stability of the slurry is judged by the change in the particle size r...

Embodiment 2

[0035] Take graphite II (D50:50um), CMC, SBR, Sp, oxalic acid and deionized water. According to mass percentage: 160:4:4:3:400, use XFZH planetary dispersion stirring vacuum mixer to stir for 10h. A negative electrode slurry with uniform dispersion and good stability is obtained. Take 200ml of this negative electrode slurry and place it in a colorless and transparent glass separatory funnel. Measure the particle size distribution of the upper and lower slurry particles when the slurry is placed for 0h, 2h, 4h, 6h, 8h, 10h, 12h, 16h, 20h, 24h, and calculate the particle size ratio of the upper and lower layers, and draw the upper and lower layers The relationship between particle size ratio and time is a2. When testing, take the slurry 1cm away from the surface and bottom of the suspension for testing.

Embodiment 3

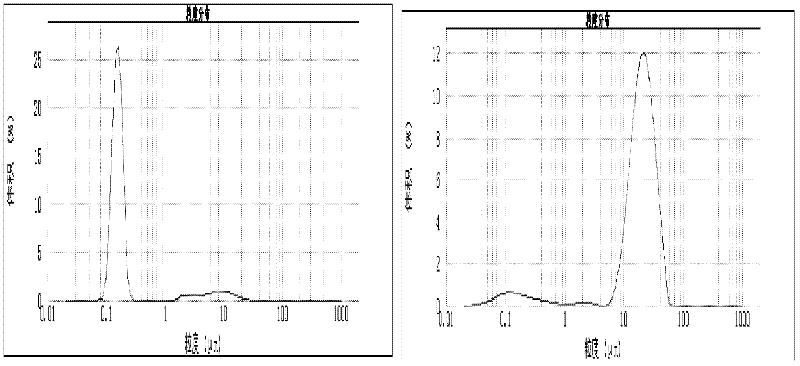

[0037] Take graphite III (D50:15um), CMC, SBR, Sp, oxalic acid and deionized water. According to mass percentage: 160:4:4:3:400, use XFZH planetary dispersion stirring vacuum mixer to stir for 10h. A negative electrode slurry with uniform dispersion and good stability is obtained. Take 200ml of this negative electrode slurry and place it in a colorless and transparent glass separatory funnel. Measure the particle size distribution of the upper and lower slurry particles when the slurry is placed for 0h, 2h, 4h, 6h, 8h, 10h, 12h, 16h, 20h, 24h, and calculate the particle size ratio of the upper and lower layers, and draw the upper and lower layers The relationship between particle size ratio and time is a3. When testing, take the slurry 1cm away from the surface and bottom of the suspension for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com