Manufacturing method for serrated aperture with random radius

A production method and sawtooth technology, which are applied in the directions of optics, optical components, instruments, etc., to achieve the effect of easy engineering application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

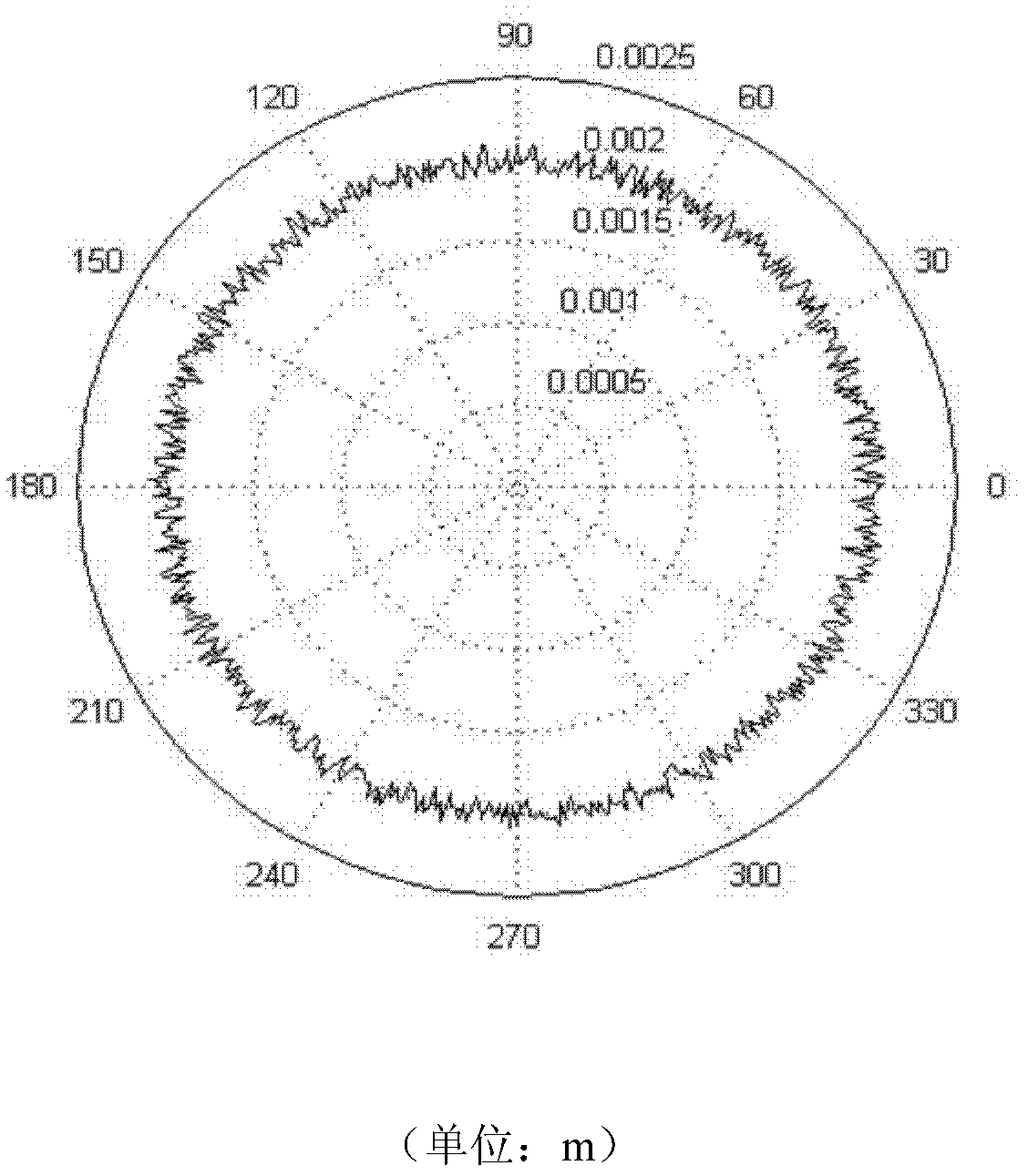

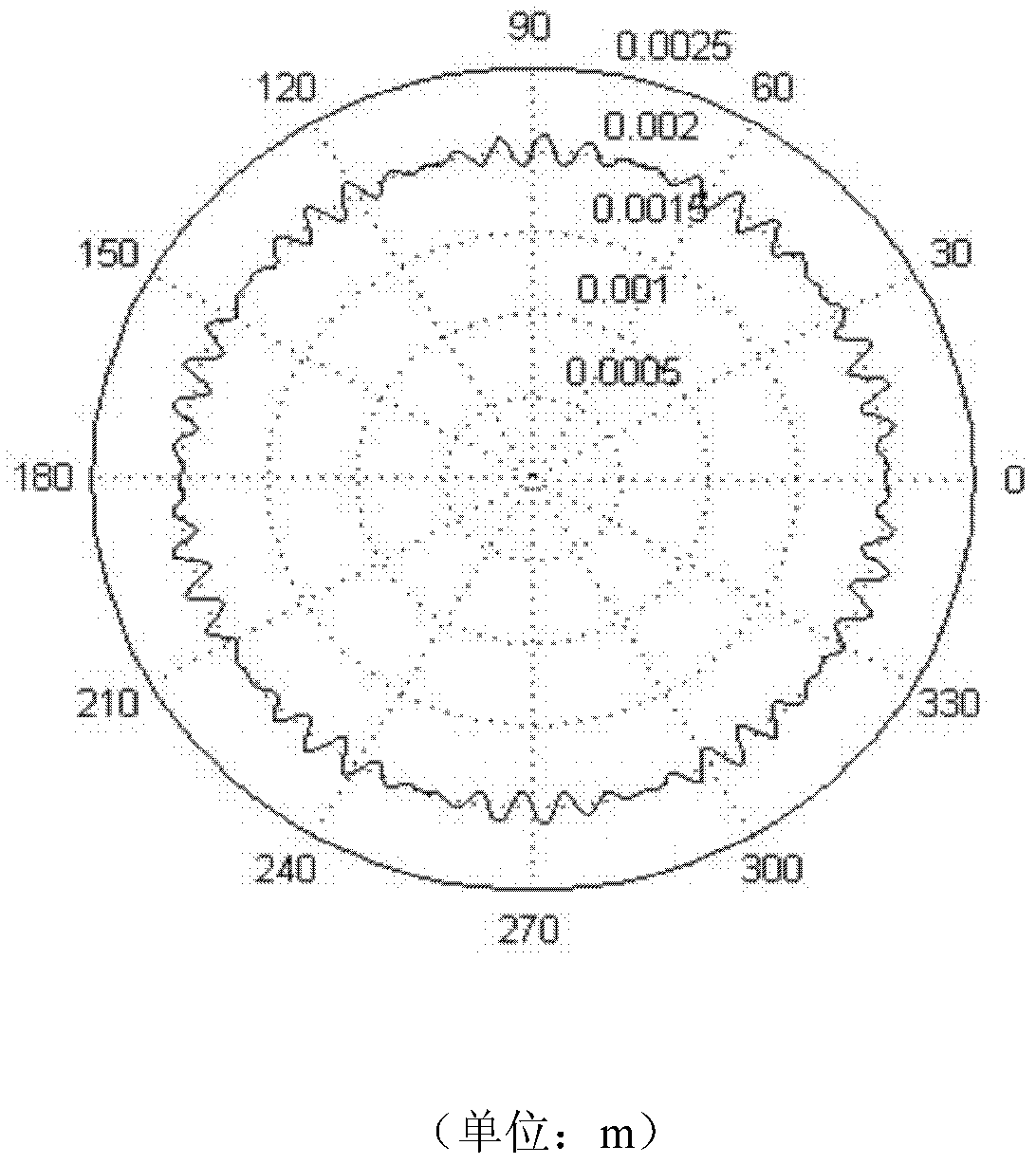

[0022] The present invention is a method of laser cutting on a stainless steel sheet, cutting out such as figure 1 The aperture of the shape shown is added to the optical path of the plane wave laser, and the light intensity distribution on the output optical axis and radial direction is measured.

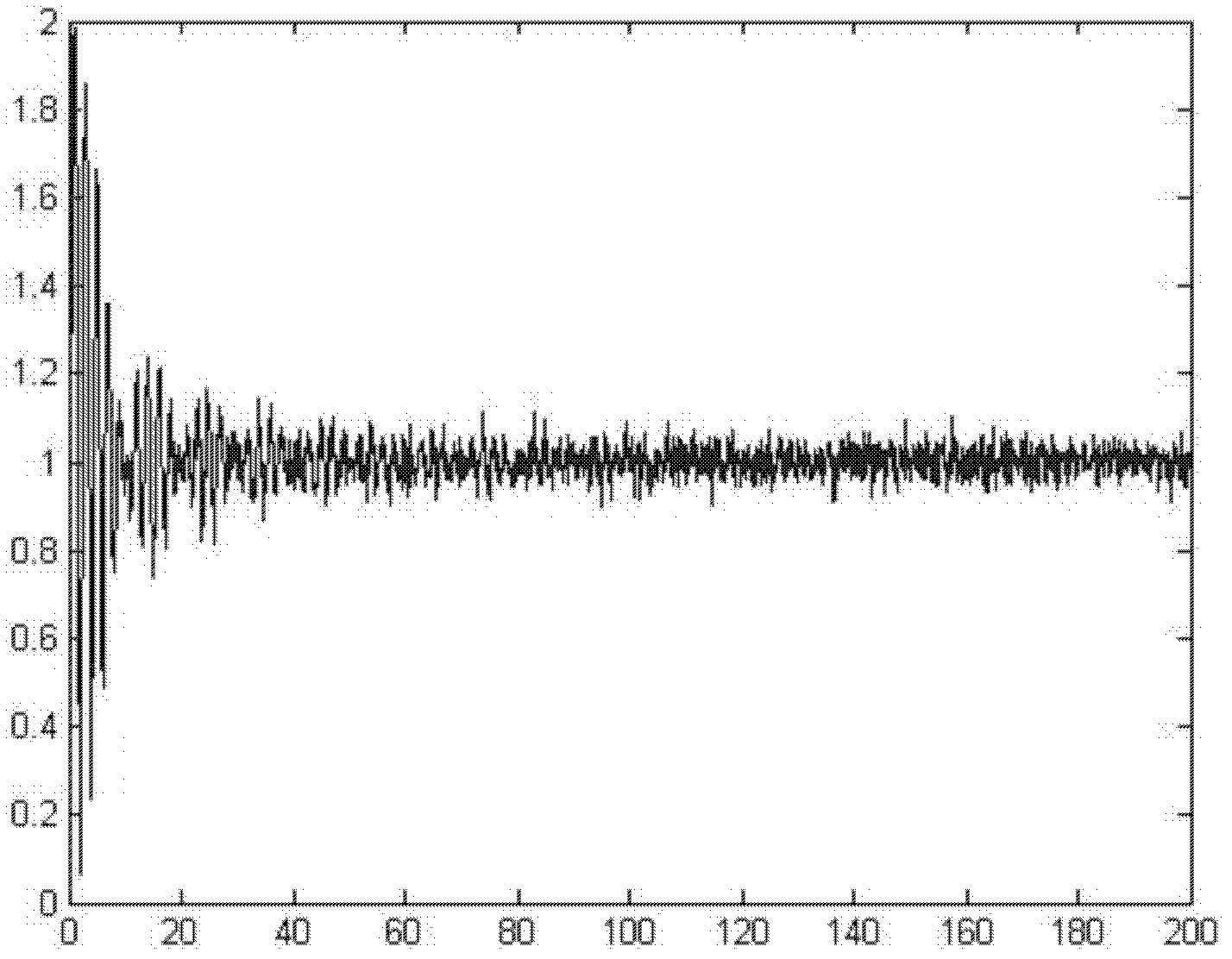

[0023] The working principle is as follows: After the laser passes through the aperture, the light intensity at any point is the sum of the wave packets at each point on the aperture area. When the edge of the aperture is a regular circle, due to Fresnel diffraction, the near The area at the edge has the same phase at the points on the axis, so constructive or destructive interference occurs, so there will be points on the axis with very strong light intensity, see Figure 5 , there will also be zero points, from Figure 8 It can also be seen that the light intensity fluctuates greatly in the center, which is easy to damage the laser working material. The amplitude modulation corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com