Three-dimensional hollow light spot generating method and device

A technology for generating devices and light spots, which is applied in the field of super-resolution microscopy and can solve the problems of low resolution and large axial size of three-dimensional hollow light spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

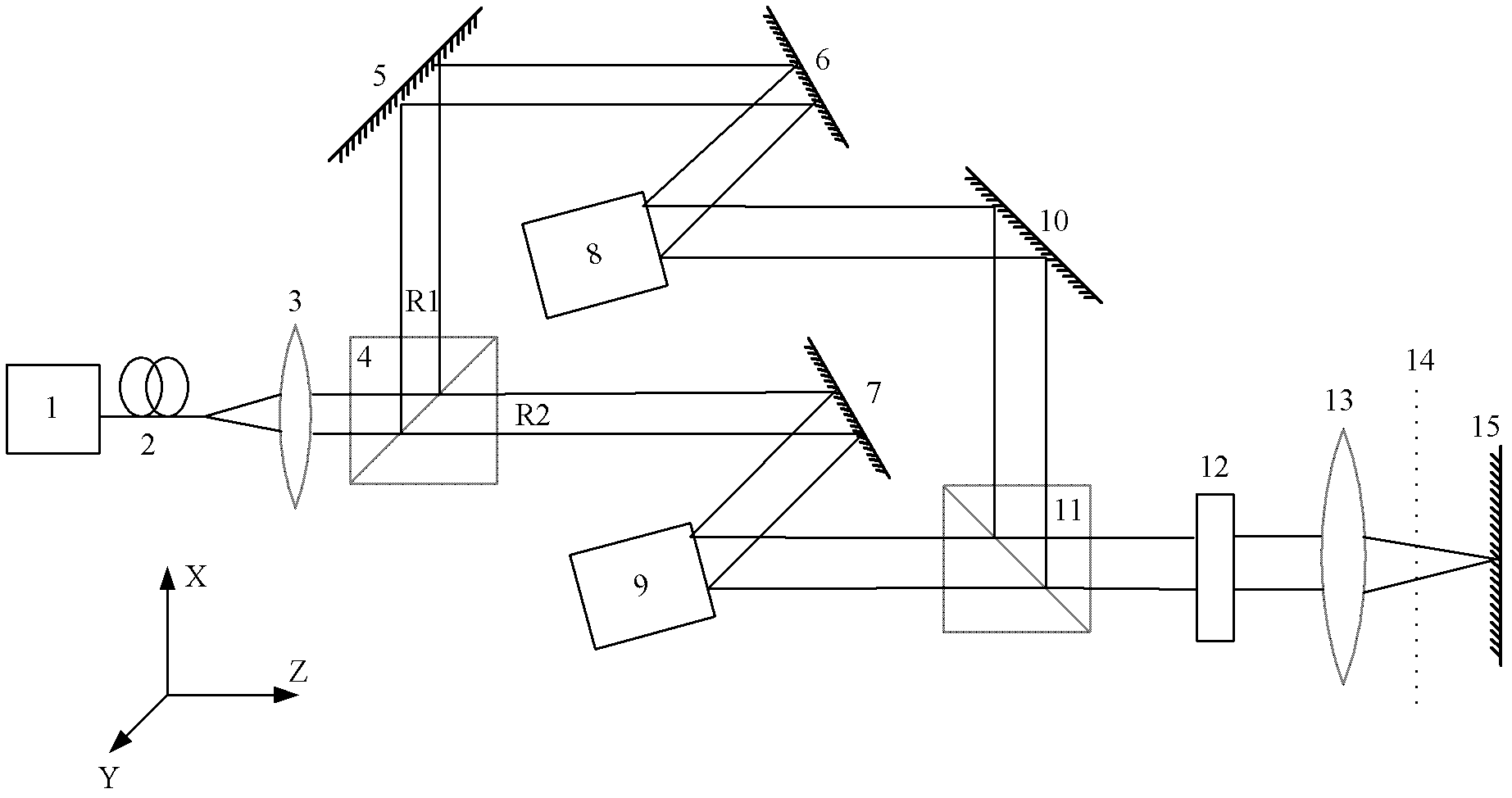

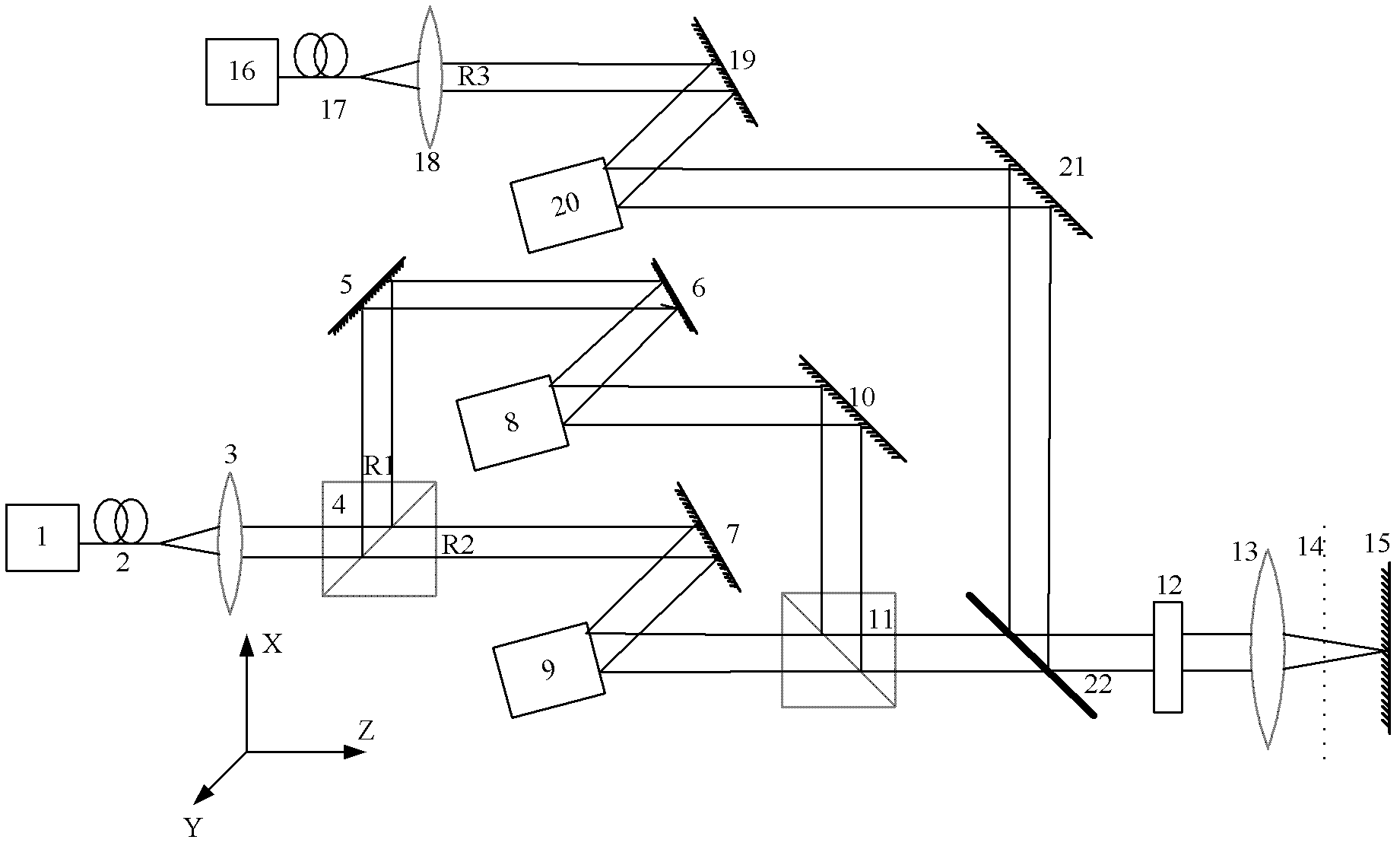

[0053] Such as figure 1 As shown, a three-dimensional hollow spot generating device includes: a first laser 1, a first single-mode fiber 2, a first collimator lens 3, a first polarization beam splitter prism 4, a first mirror 5, and a second mirror 6 , the third mirror 7, the first phase modulator 8, the second phase modulator 9, the fourth mirror 10, the second polarization beam splitter prism 11, 1 / 4 wave plate 12, microscope objective lens 13, sample surface 14, Dielectric film mirror 15.

[0054] Wherein, the first single-mode optical fiber 2 and the first collimating lens 3 are located on the optical axis of the beam emitted by the first laser 1, and the beam emitted by the first laser 1 is collimated to obtain a collimated beam; the first polarization splitting The prism 4 is located on the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com