Liquid-cooled radiating device

A liquid-cooled heat dissipation and liquid-cooled head technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve problems that do not meet energy conservation and environmental protection, and achieve design cost saving, cost reduction, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

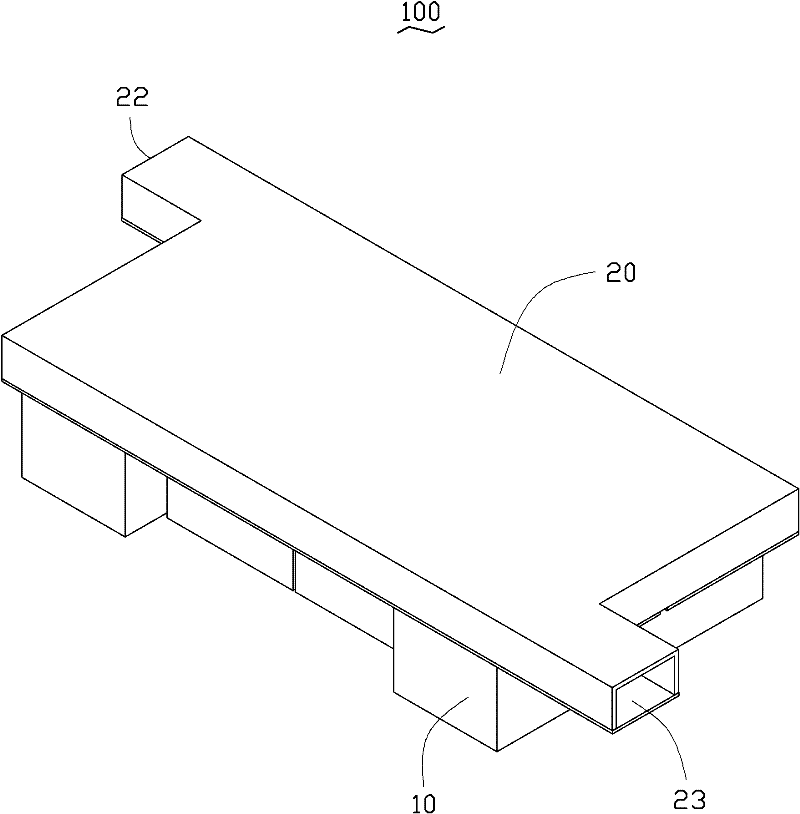

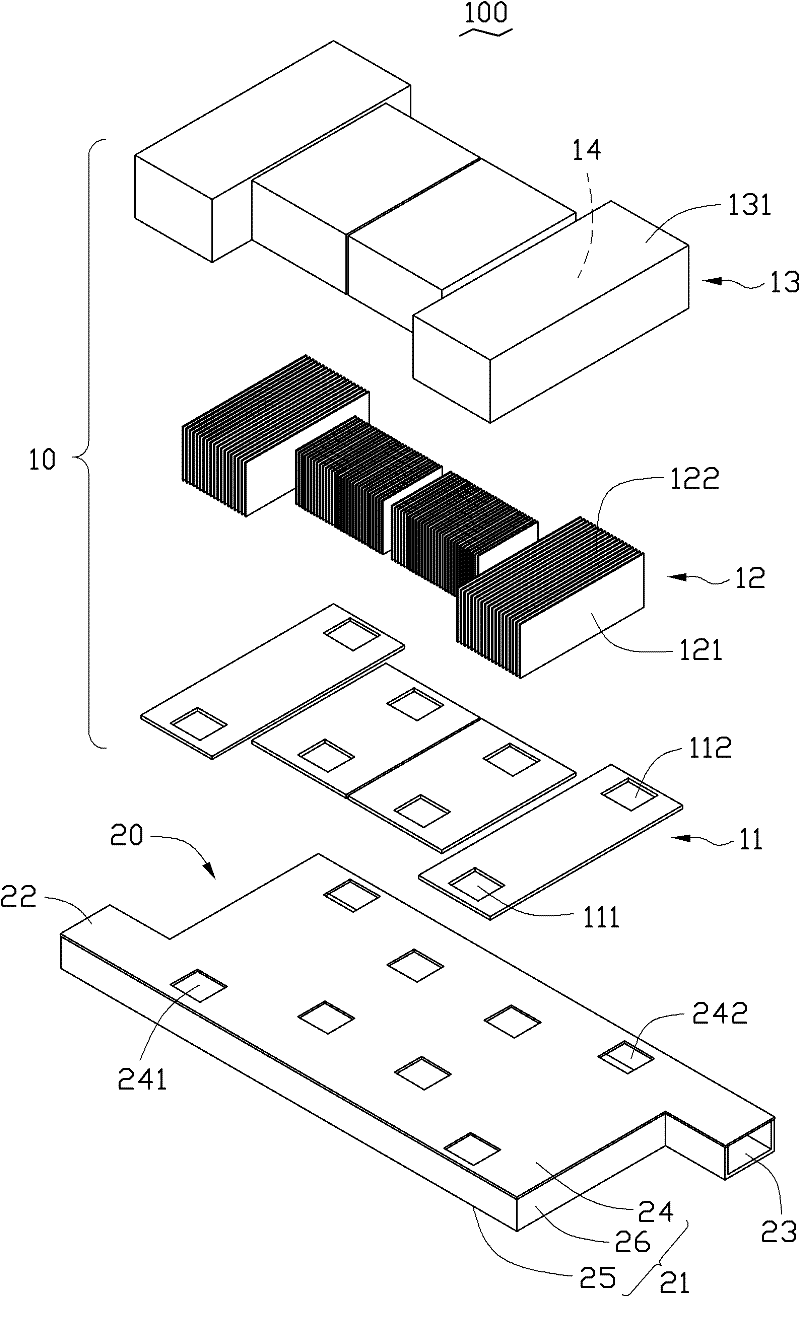

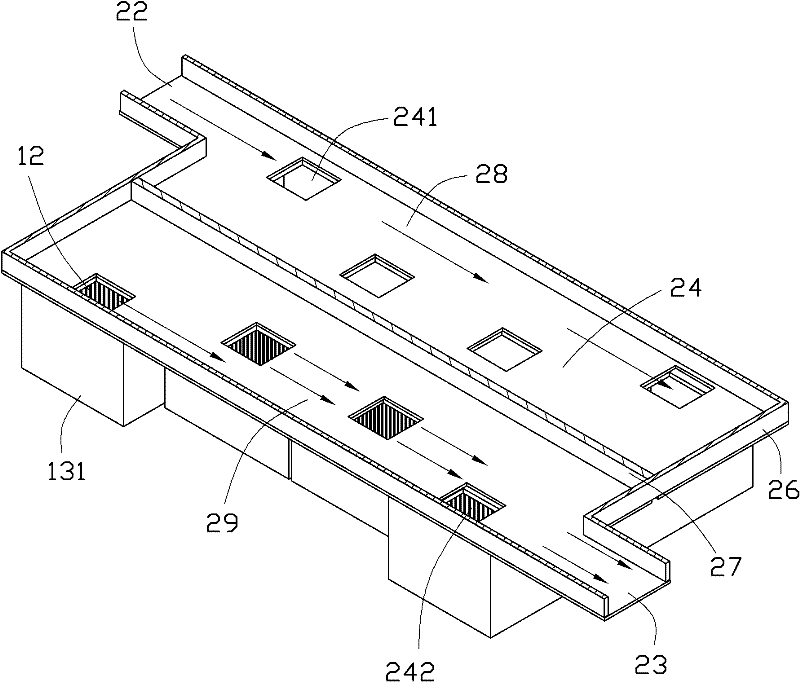

[0034] figure 1 and figure 2 Shown is a liquid cooling heat sink 100 according to an embodiment of the present invention. The liquid cooling device 100 is used to dissipate heat for an electronic device, such as a plurality of heat-generating electronic components in a containerized data center. The liquid cooling device 100 includes a box body 20 and a plurality of liquid cooling heads 10 combined at the bottom of the box body 20 . The plurality of liquid cooling heads 10 are used to respectively contact with a plurality of heat-generating electronic components (not shown in the figure) so as to respectively absorb the heat generated by the plurality of heat-generating electronic components. In this embodiment, the cooling medium is water. Understandably, the cooling medium can also be other liquids.

[0035] Each liquid cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com