Surface plasmon resonance rectenna and preparation method therefor

A technology of surface plasmon and rectenna, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of high technical cost, unsuitable for large-scale, industrial production, etc., to improve transmission efficiency and reduce loss , the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

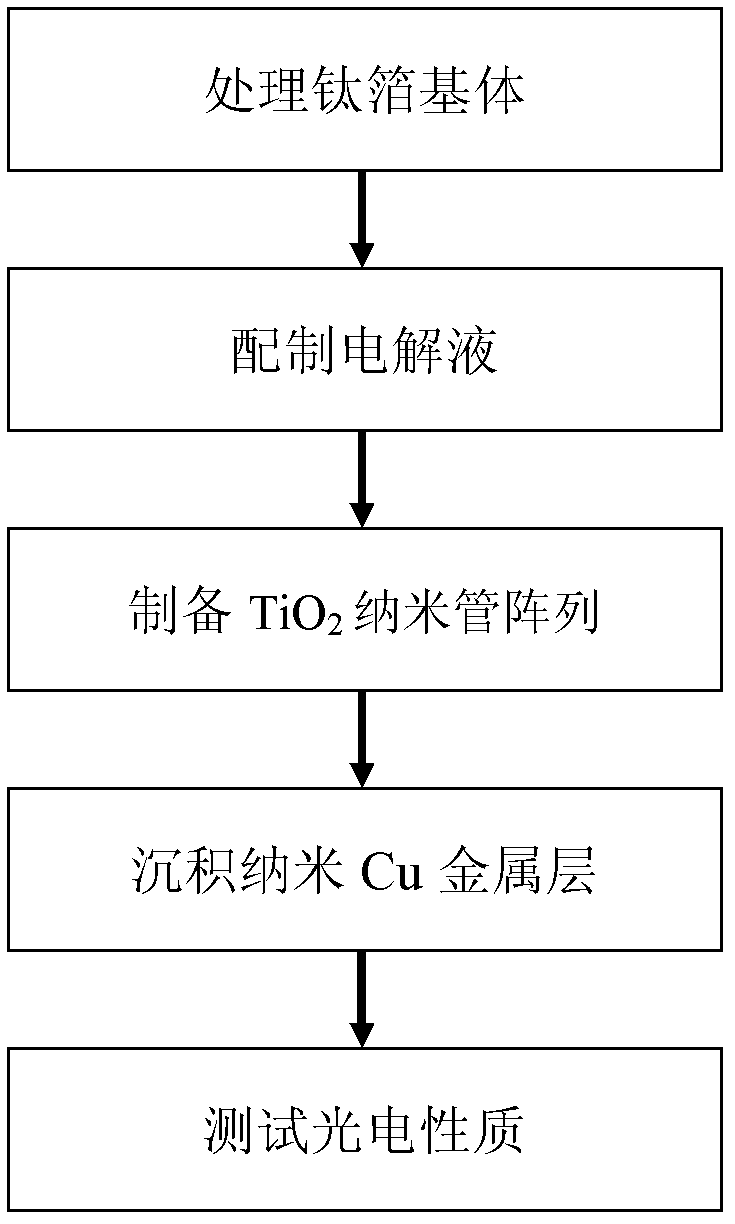

Method used

Image

Examples

Embodiment 1

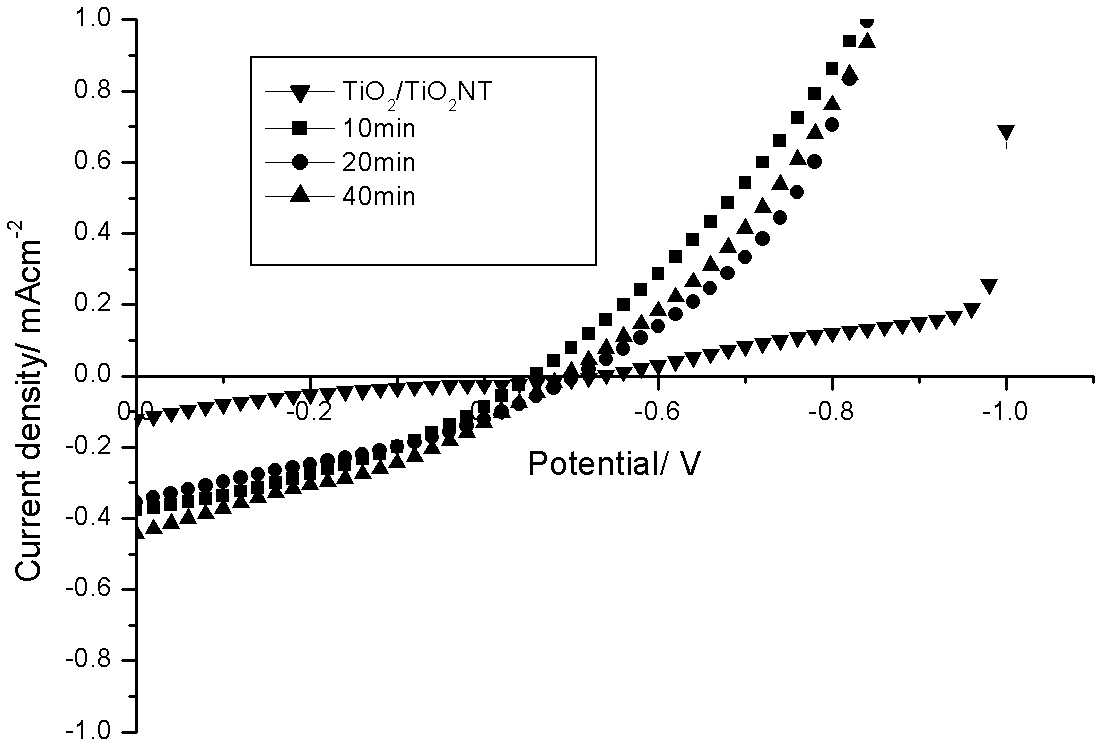

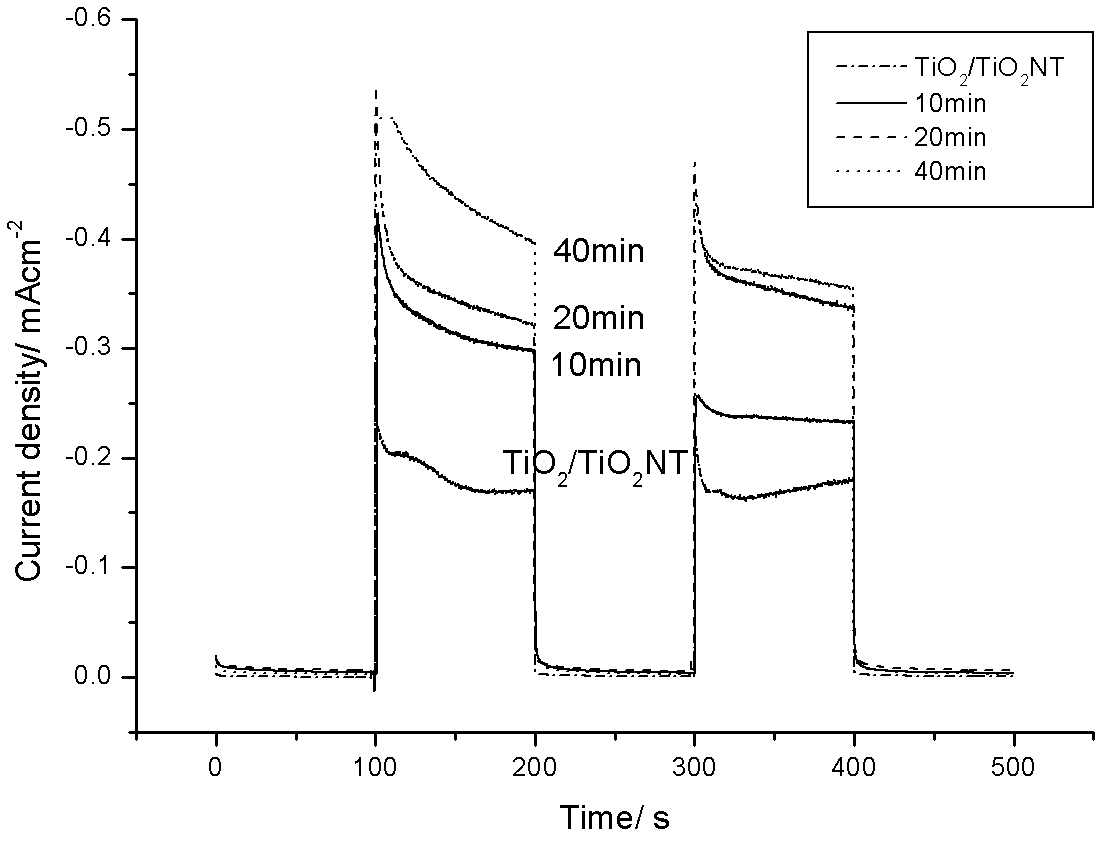

[0038] This embodiment is a surface plasmon resonance rectenna. The surface plasmon resonance rectenna is Ti / TiO 2 NT / Cu structure, specifically, the surface plasmon resonance rectenna has three layers, the lower layer is metal Ti, and TiO is oxidized on one surface of metal Ti 2 nanotube array layer, the TiO 2 A Cu nanoparticle metal layer is deposited on the surface of the nanotube array layer. The TiO in the middle of the surface plasmon resonance rectenna 2 The nanotube array layer is a heterogeneous layer. The TiO 2 The inner pore diameter of the nanotube array is 100±10 nm, and the tube length is 2.2±0.2 μm. The photodeposition process was irradiated with 1% power for 10 minutes. The product size is Φ5mm and the color is gray.

[0039] The microscopic surface morphology of the Cu nanoparticle metal layer is nanoparticles, the particle size is 50-80nm, no specific shape, attached to the TiO 2 On the tube wall on the surface of the nanotube substrate, a small amoun...

Embodiment 2

[0049] This embodiment is a surface plasmon resonance rectenna. The surface plasmon resonance rectenna is Ti / TiO 2 NT / Cu structure, specifically, the surface plasmon resonance rectenna has three layers, the lower layer is metal Ti, and TiO is oxidized on one surface of metal Ti 2 nanotube array layer, the TiO 2 A Cu nanoparticle metal layer is deposited on the surface of the nanotube array layer. The TiO in the middle of the surface plasmon resonance rectenna 2 The nanotube array layer is a heterogeneous layer. The TiO 2 The inner pore diameter of the nanotube array is 100±10 nm, and the tube length is 2.2±0.2 μm. The photodeposition process was irradiated with 1% power for 20min. The product size is Φ5mm, and the color is gray-green.

[0050] The microscopic surface morphology of the Cu nanoparticle metal layer is nanoparticles, and its particle size is 100-150nm, without a specific shape, and its distribution density becomes larger, and it adheres to the TiO 2 On the...

Embodiment 3

[0060] This embodiment is a surface plasmon resonance rectenna. The surface plasmon resonance rectenna is Ti / TiO 2 NT / Cu structure, specifically, the surface plasmon resonance rectenna has three layers, the lower layer is metal Ti, and TiO is oxidized on one surface of metal Ti 2 nanotube array layer, the TiO 2 A Cu nanoparticle metal layer is deposited on the surface of the nanotube array layer. The TiO in the middle of the surface plasmon resonance rectenna 2 The nanotube array layer is a heterogeneous layer. The TiO 2 The inner pore diameter of the nanotube array is 100±10 nm, and the tube length is 2.2±0.2 μm. The photodeposition process was irradiated with 1% power for 40min. The product size is Φ5mm, and the color is light dark red.

[0061] The microscopic surface morphology of this embodiment is Cu nanorods with different growth directions, the length is between 300nm and 650nm, and the width is basically constant, which is 110±5nm. There are a small amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com