LED packaging method and structure

A technology of LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation, complex packaging process, and poor heat dissipation of LED packaging structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings.

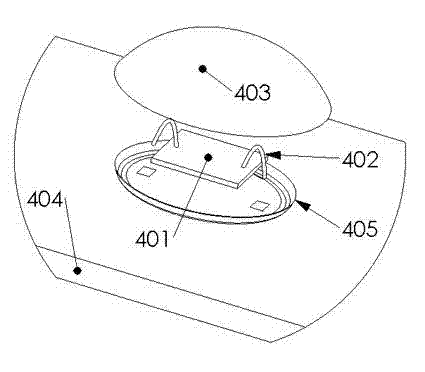

[0066] see figure 1 , which is a LED packaging structure, including: LED chips 401 , inner leads 402 , filling colloid 403 , circuit board 404 , and reflective bowl 405 .

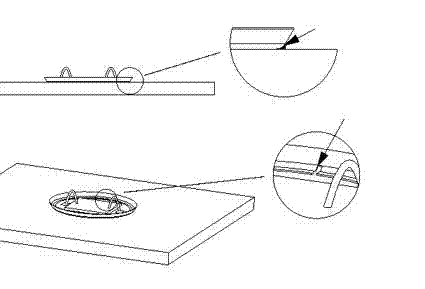

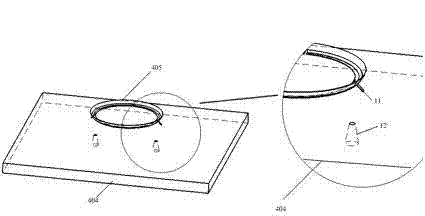

[0067] For a better heat dissipation effect, the circuit board 404 may be made of a material with high thermal conductivity, such as metal or ceramic. The mounting position of the circuit board 404 and the LED chip 401 can also be a plane, a square groove, a rectangular groove, a circular groove, and the like. And in order to fix the LED chip, the circuit board 404 can be connected to the LED chip 401 by dotted with silver glue, gold tin, or insulating heat-conducting glue, or soldering material. In addition, the position of the LED chip 401 can be fixed on the circuit board 404, and a reflective bowl can be added to improve the light extraction efficiency. In order to ensure the shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com