Expandable mounting head for chip mounter

A technology of placement head and placement machine, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of complex assembly, increased installation difficulty, and high cost, and achieves convenient structural installation, fast placement speed, and high placement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

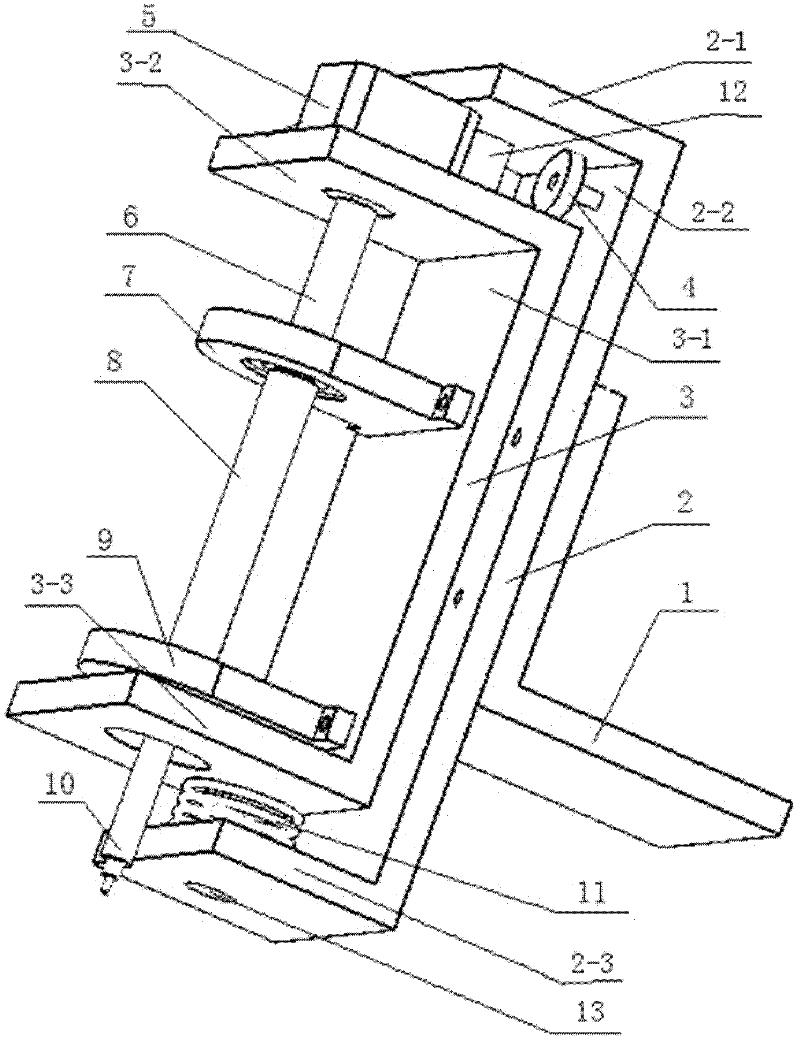

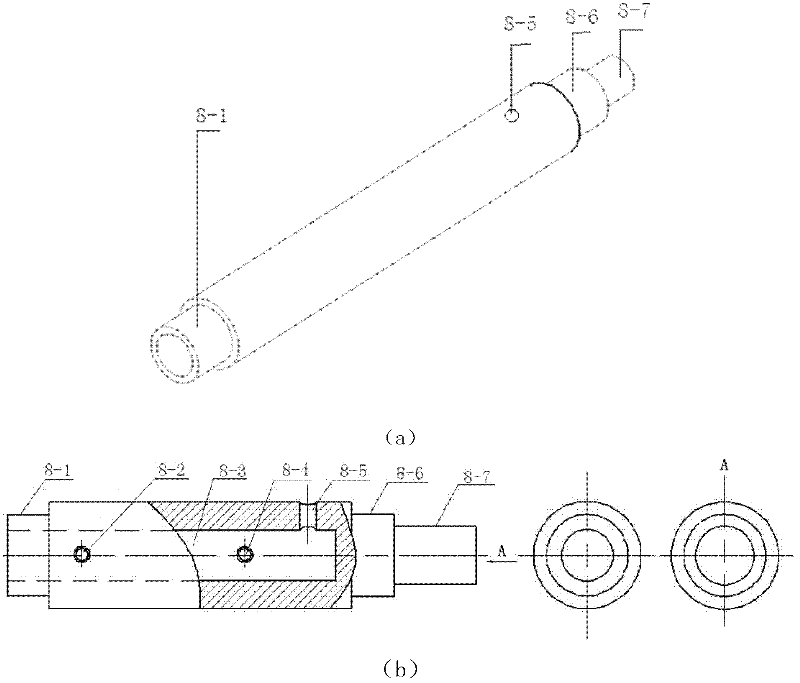

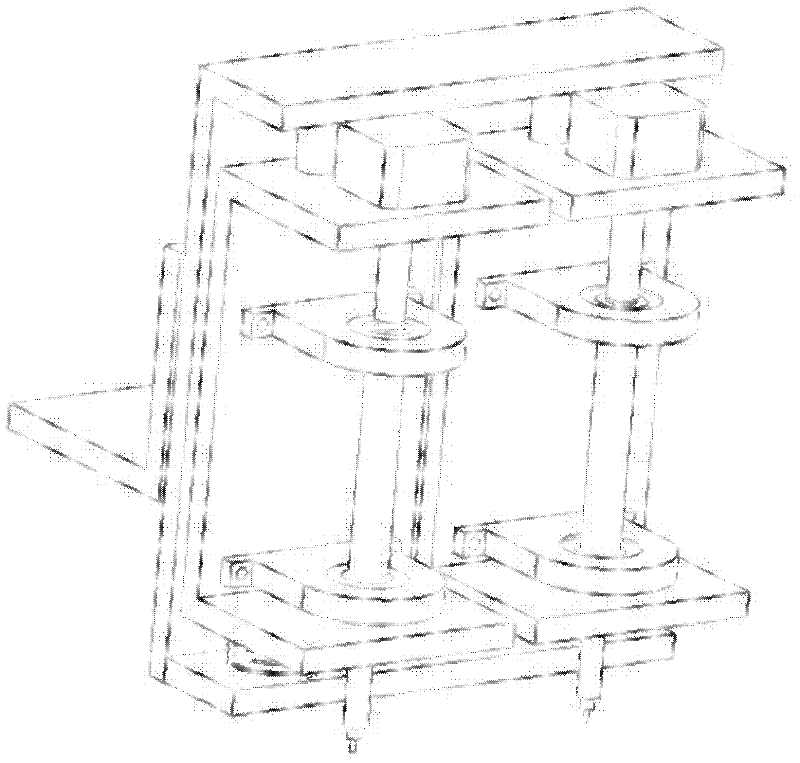

[0027] See Figure 1 ~ Figure 3 , The expandable placement head of the present invention includes a support base 2, a guide rail base 3, a cam 4, a reduction stepper motor 5, a coupling 6, and a hollow tube 8.

[0028] Among them, the supporting seat 2 is a "U"-shaped frame composed of the supporting seat rear plate 2-1 and the supporting seat top plate 2-2 and the supporting seat bottom plate 2-3 at both ends; the guide rail seat 3 is composed of the guide rail seat rear plate 3- 1 and the "U"-shaped frame composed of the rail seat top plate 3-2 and the rail seat bottom plate 3-3 at both ends; the length of the rail seat rear plate 3-1 is smaller than the length of the support seat rear plate 2-1.

[0029] The support seat top plate 2-2 and the support seat bottom plate 2-3 are both provided with a through hole 13 in the center position. The rail seat top plate 3-2 is equipped with a rail shaft 12 perpendicular to the guide rail seat top plate 3-2, and the guide rail seat bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com