Method for producing reconstructed tobacco sheets by low-CO papermaking

A technology of tobacco sheet and manufacturing method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of weak human control ability and complex chemical composition of tobacco leaves, and achieve the effects of improving comfort, reducing bad breath, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

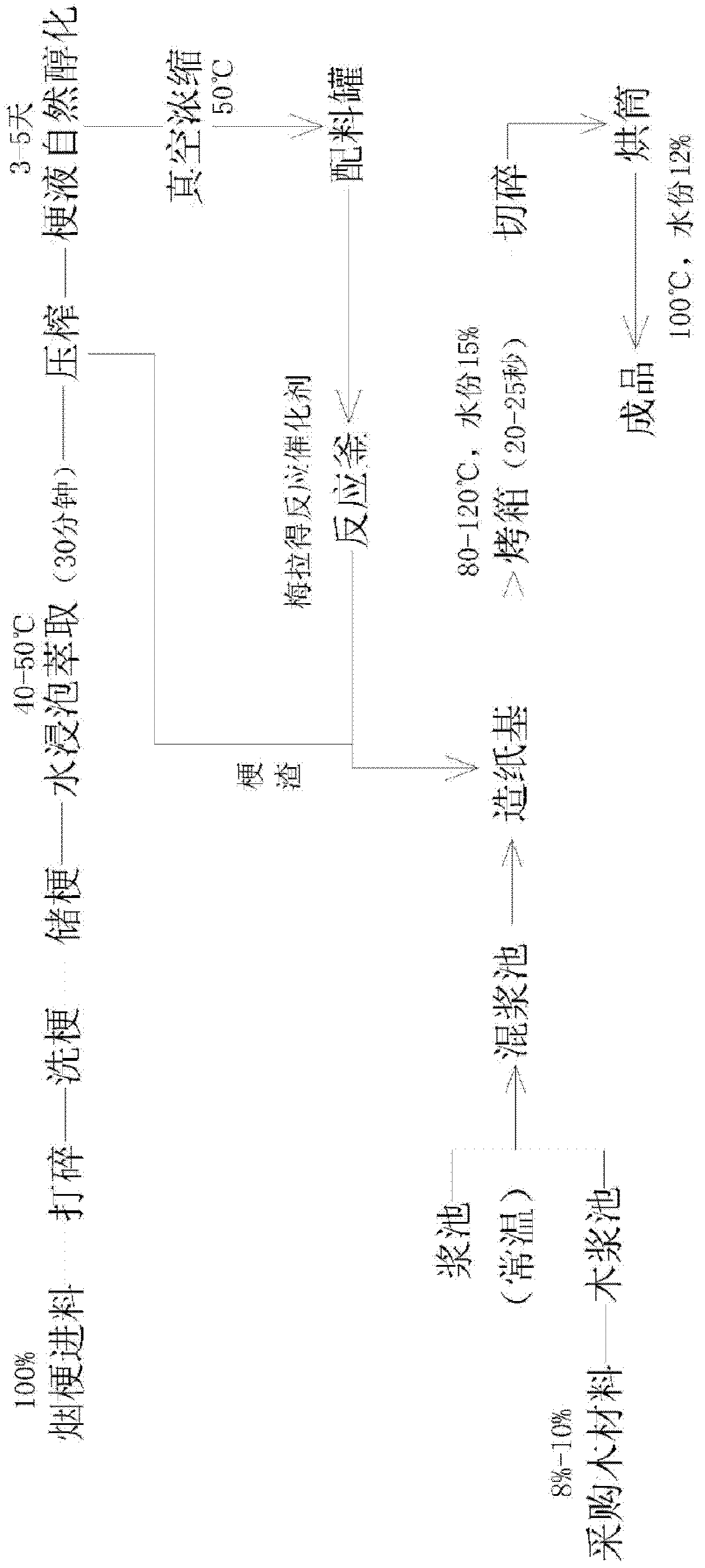

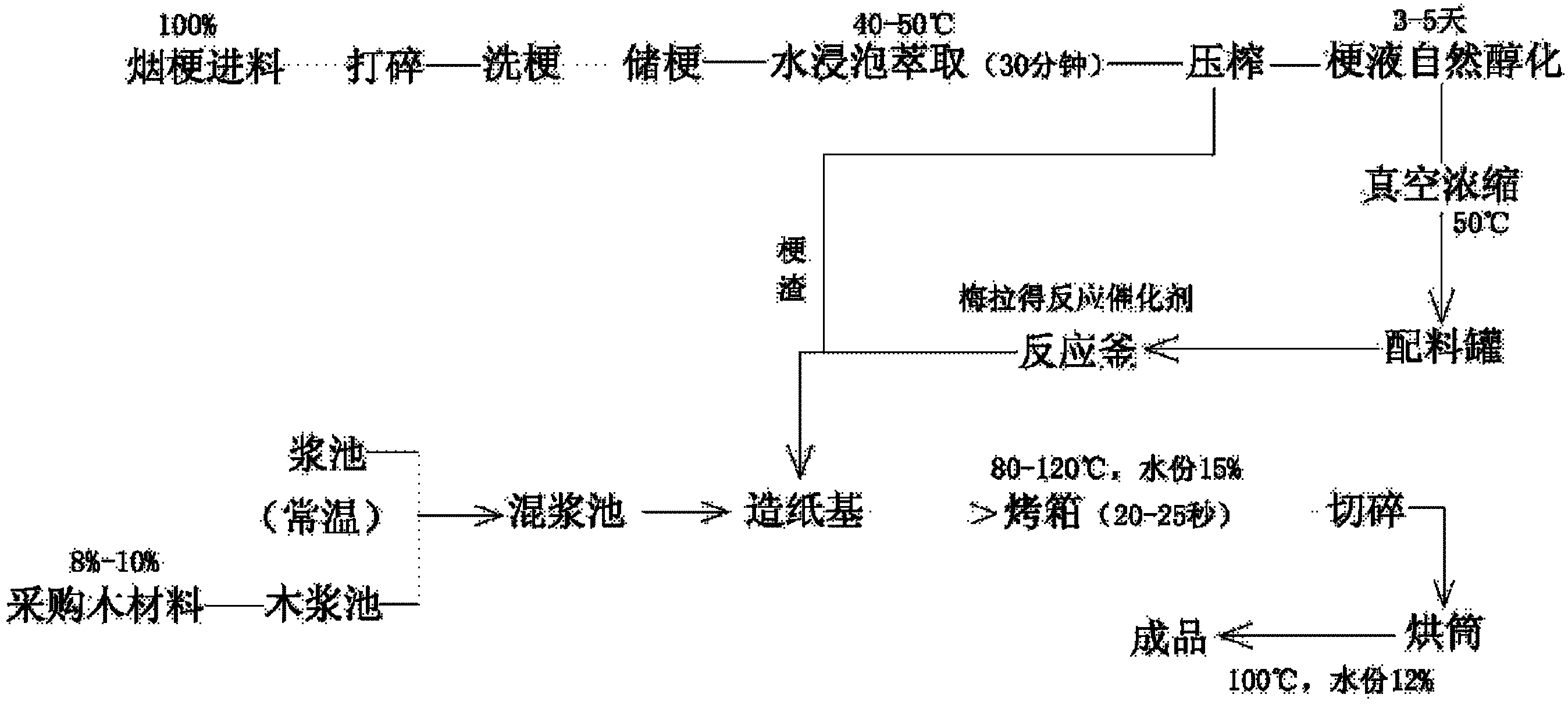

[0019] Example: Combine figure 1 , the manufacture method of the low-CO papermaking method tobacco sheet of the present embodiment, carry out as follows:

[0020] a. First feed the raw material of flue-cured tobacco stems, wherein the short stem content of flue-cured tobacco is 100%;

[0021] b. Carry out secondary circulation extraction on the raw material in step a, specifically, the water soaking extraction method can be adopted, the extraction temperature is 40-50°C, and the extraction time is 30 minutes. Aging for 3-5 days, the natural aging is equal to the natural aging of tobacco leaves;

[0022] c. Dissolving and stirring the Maillard reaction catalyst accounting for 0.5% to 3% of the raw material weight percentage in water at 100°C, and mixing uniformly to obtain a catalyst solution, the Maillard reaction catalyst being diammonium hydrogen phosphate;

[0023] d. Concentrate the alcoholized extract at 50°C to a specific gravity of 1.258±0.002, mix it with the Maillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com