Rotary fine screen for water treatment and application of rotary fine screen to water treatment

A technology of rotary grille and fine grille, applied in the direction of filtration separation, separation method, moving filter element filter, etc., can solve the problems of reducing the processing effect, worrying about the problem, difficult to increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

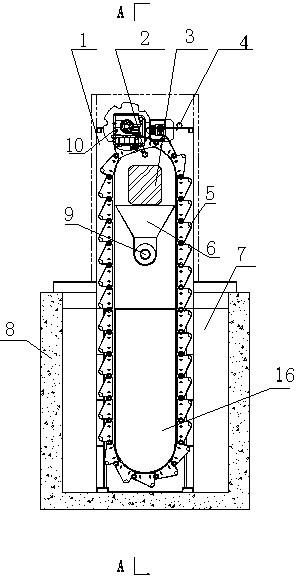

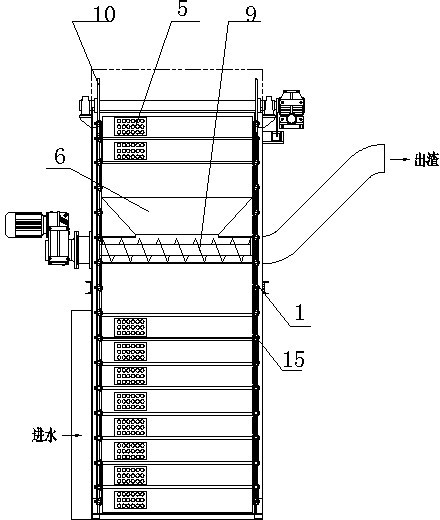

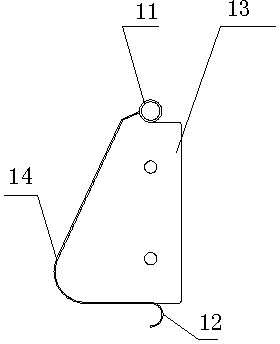

Embodiment 1

[0028] Embodiment 1: Referring to the accompanying drawings, the rotary fine grid for water treatment of the present invention includes a grid frame 1, a triangular bucket-shaped porous (aperture 0.75-2mm) monolithic strip filter plate 14 (the length is the filter plate) with one side opening. surface width) to form an annular filter screen 5 hinged with each other, and pass through the rotary chains 15 on both sides (similar to bicycle chains), and place it on the frame according to the triangular opening towards the inner ring. , There is a tubular screw press slag discharge device 9 at the bottom of the slag collecting hopper, one side of the thickness of the rotary grille is closed, and one side is open. Triangular bucket-shaped porous filter plate 14, one corner of the opening side has a hinged round tube 11, and the other corner has a hinged semicircle 12 that fits with the round tube. When forming a rotary ring filter, the adjacent triangular bucket-shaped porous filter ...

Embodiment 2

[0030] Embodiment 2: As in Embodiment 1, a woven filter screen with a finer aperture is laid on the inner surface of the triangular bucket-shaped porous filter plate 14 .

Embodiment

[0031] Embodiment 3: As mentioned above, the two side surfaces of the thickness opening 16 of the revolving fence and the water retaining block between the two side walls of the water channel are trumpet-shaped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com