Microfluidic concentration gradient droplet generating chip, generating device and application

A concentration gradient and droplet generation technology, which is applied to laboratory containers, instruments, laboratory utensils, etc., can solve the problems of narrow sample concentration range, difficulty in drug screening, and difficulty in generating droplets with different concentrations. , to achieve the effect of fast concentration gradient generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

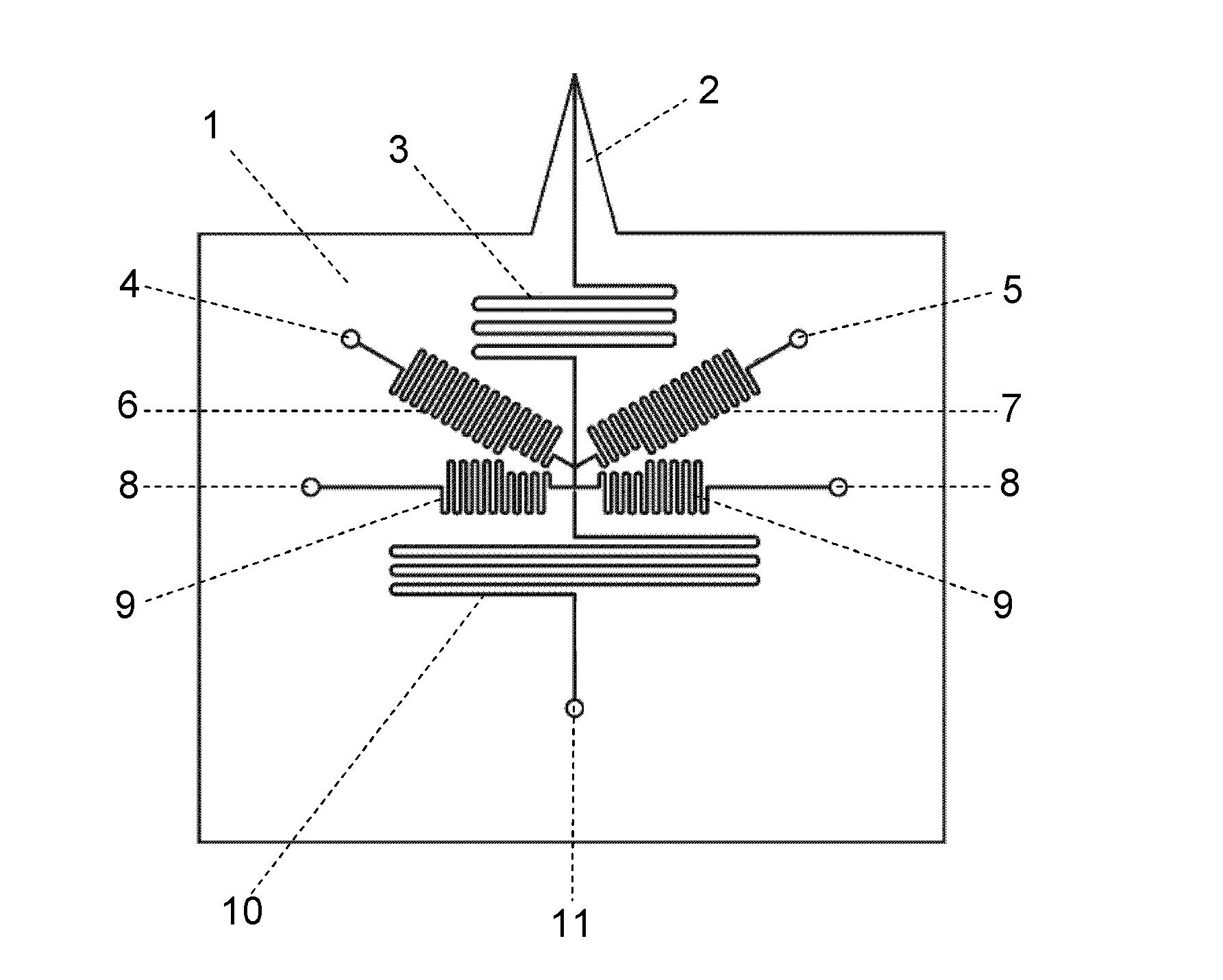

[0053] figure 1 It is a top view of the microfluidic concentration gradient droplet generation chip based on the flow injection gradient technology established according to the present invention. A sampling probe 2, a sample dispersion channel 3, a reagent channel 6 and a reagent channel 7, two immiscible phase channels 9, a droplet reaction and a detection channel 10 are processed on the chip substrate 1 by micromachining. The inlet end of the sample dispersing channel 3 is provided with a sampling probe 2, and the end of the sample dispersing channel 3 is connected with the outlet ends of the sample channels 6 and 7 and the outlet end of the immiscible phase channel 9 successively, and the sample dispersing channel 3 The outlet port of the droplet reaction and detection channel 10 is then communicated with the inlet port. The outlet end of the reagent channel 6 and the outlet end of the reagent channel 7 are arranged on both sides of the same cross-sectional position at the...

Embodiment 2

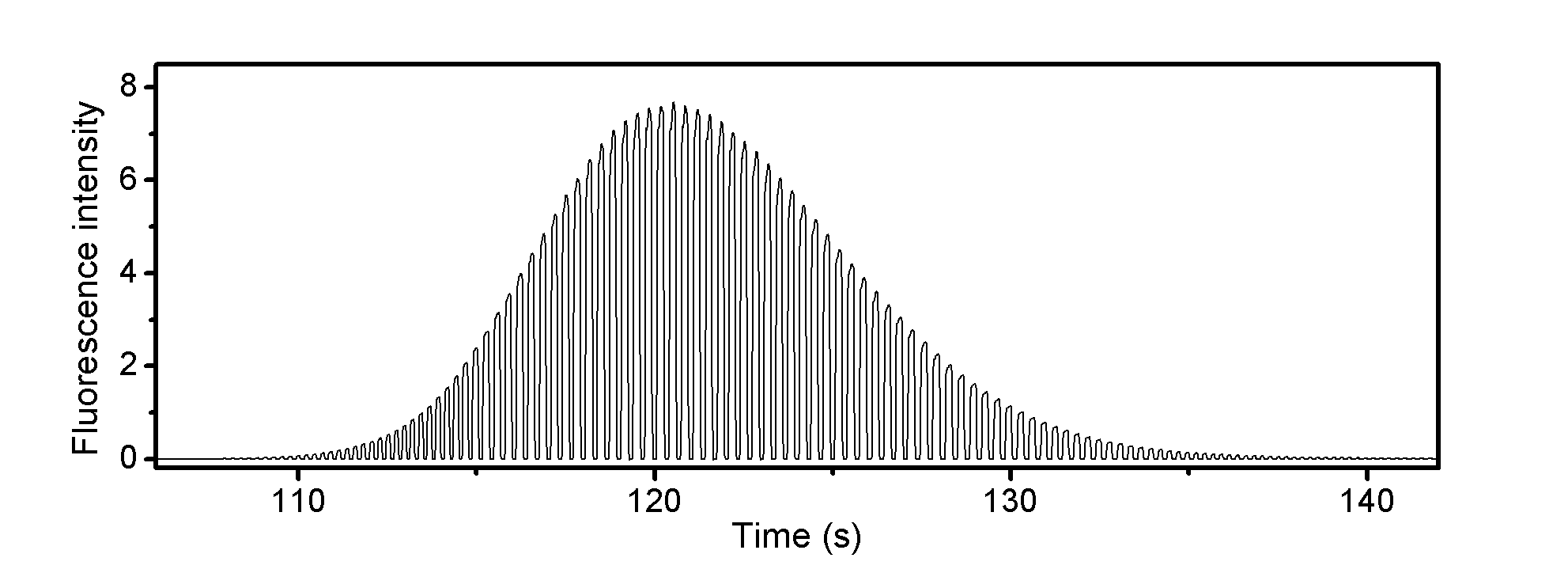

[0066] Figure 4 It is a recording chart of enzyme inhibition analysis results using the chip of Example 1 and taking a β-galactosidase inhibitor 2-phenylethyl-β-D-thiogalactoside (PETG) solution as a sample.

[0067] Specifically, 10mM tris(pH7.3) is used as carrier liquid, PETG solution is used as sample solution, β-galactosidase solution and substrate FDG solution are used to react with sample, tetradecane is used as immiscible phase.

[0068] The specific operation is as follows: the sampling probe 2 is inserted into a 10 mM tris (pH 7.3) solution containing a carrier liquid, and the sample dispersion channel is pre-filled with the carrier liquid. The two syringes used to drive the immiscible phase are filled with immiscible phase tetradecane and connected to the inlet port 8 of the immiscible phase channel 9 to provide positive pressure drive, and the immiscible phase tetradecane is injected into the immiscible phase channel 9 Inside, the immiscible phase channel 9 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com