Residual sludge cell wall breaking method

A technology for excess sludge and cells, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long sludge residence time, complicated operation and management, and large pool volume. Achieve the effect of reduced sludge volume, high efficiency and improved dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

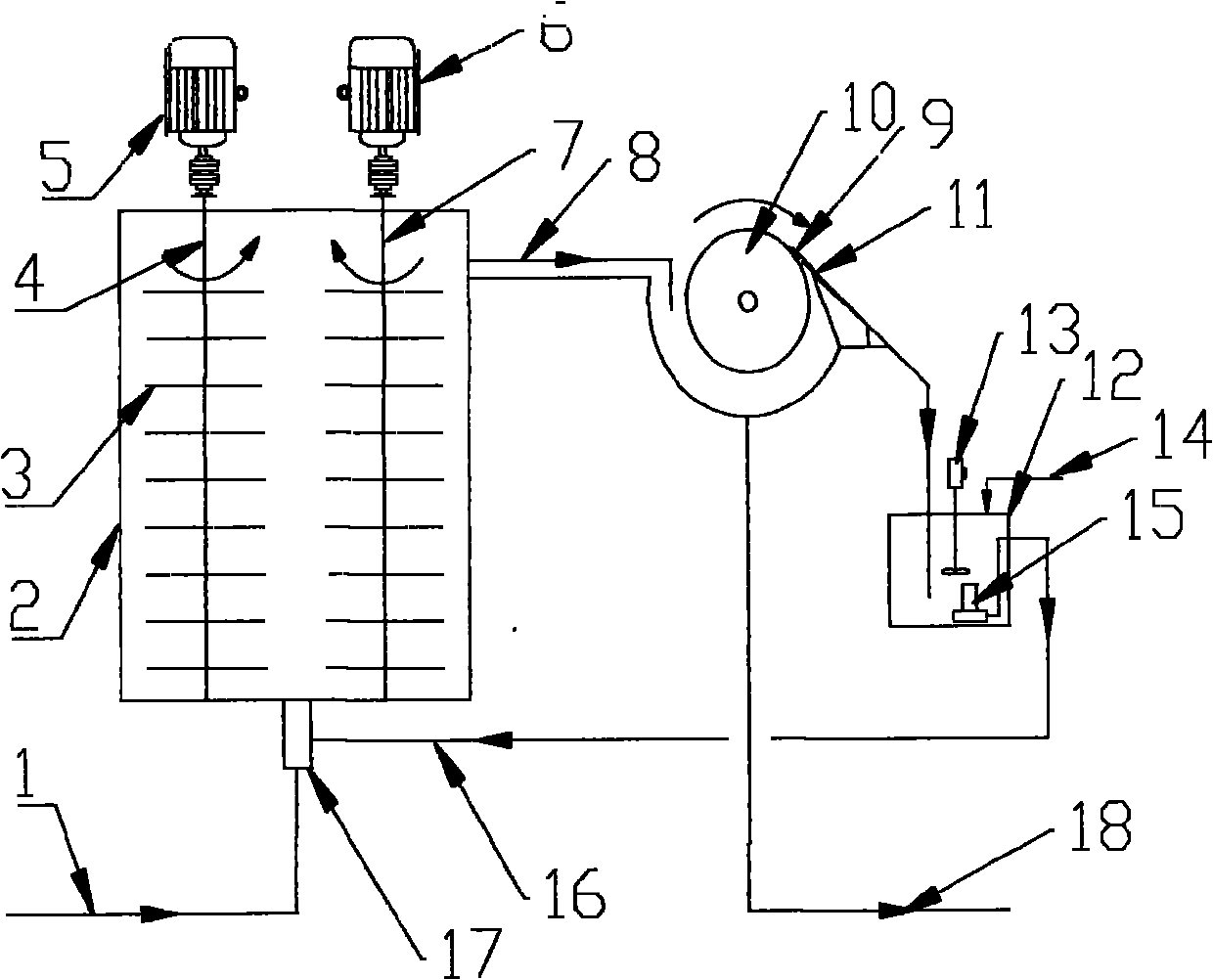

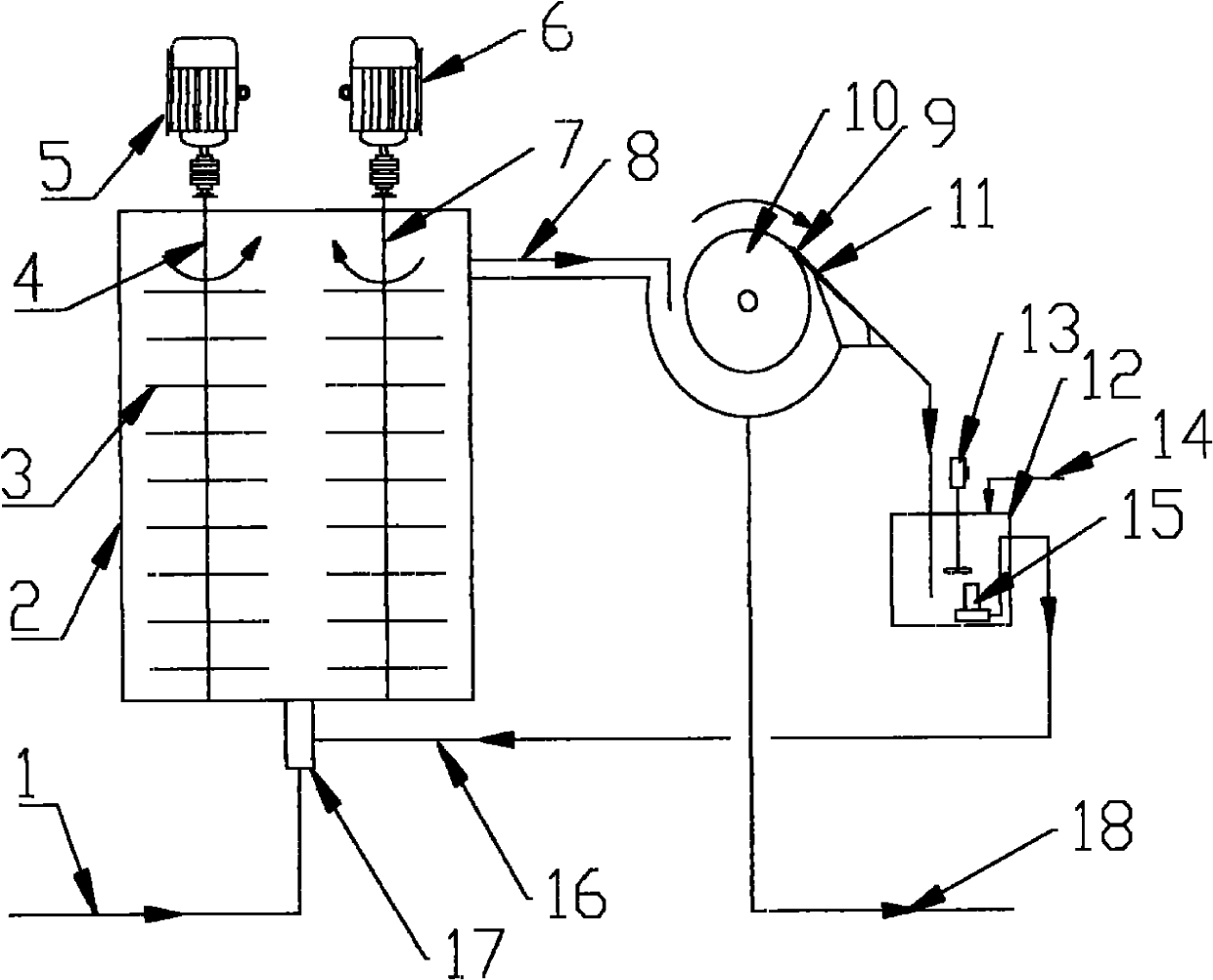

[0022] Fe with a particle size of 45um 3 O4 powder is added in the magnetic powder buffer tank 12, and the Fe is regulated by the magnetic powder agitator 13 and the magnetic powder supplementary water inlet 14. 3 Concentration of O4 powder according to Fe 3 The weight ratio of O4 powder to residual sludge is 5%. 3 O4 powder into the sludge breaking device 2, there are two sets of cutting blades 3 rotating at high speed in the sludge breaking device 2, the speed of the driving motor 1 5 is controlled at 750r / min, and the speed of the driving motor 2 6 is controlled at 750r / min, the rotation direction of drive shaft one 4 is opposite to the rotation direction of drive shaft two 7. The remaining sludge enters the sludge breaking device 2 from the sludge inlet 1, and the mixer 17 mixes the sludge with Fe 3 After the O4 powder is mixed, under the action of the cutting blade 3, the Fe 3 O4 powder exerts strong impact, shear and friction on the sludge to achieve rapid wall brea...

Embodiment 2

[0025] In the present embodiment, do not add magnetic powder, specifically as follows:

[0026] The remaining sludge enters the sludge breaking device 2 from the sludge inlet 1. The sludge breaking device 2 is composed of two sets of cutting blades 3 rotating at high speed. The speed of the driving motor 5 is controlled at 750r / min, and the driving motor The rotating speed of two 6 is controlled at 750r / min, and the direction of rotation of drive shaft one 4 is opposite to the direction of rotation of drive shaft two 7. The broken sludge flows out from the sludge outlet 8 at the top of the sludge breaking device.

[0027] Sampling 200ml at the sludge outlet 8, measuring the SCOD value of the supernatant soluble organic oxygen consumption, sampling 200ml at the sludge inlet 1, measuring the total organic oxygen consumption TCOD of the mixed solution. The ratio of SCOD / TCOD is the wall breaking rate, and the wall breaking rate of the remaining sludge after testing is 2.48%.

Embodiment 3

[0029] γ-Fe with a particle size of 100um 2 o 3 The powder is added into the magnetic powder buffer tank 12, and the γ-Fe 2 o 3 Powder concentration, according to γ-Fe 2 o 3 The weight ratio of powder to remaining sludge is 5%. Add γ-Fe through the magnetic powder feeding port 16 2 o 3 Powder into the sludge breaking device 2, there are two groups of cutting blades 3 rotating at high speed in the sludge breaking device 2, the speed of the driving motor 1 5 is controlled at 800r / min, and the speed of the driving motor 2 6 is controlled at 800r / min min, the rotation direction of drive shaft one 4 is opposite to the rotation direction of drive shaft two 7 . The remaining sludge enters the sludge breaking device 2 from the sludge inlet 1, and the mixer 17 mixes the sludge with γ-Fe 2 o 3 After powder mixing, under the action of cutting blade 3, γ-Fe 2 o 3 The powder has a strong impact, shear, friction and other effects on the sludge to achieve rapid wall breaking of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com