Residual sludge cell wall breaking system and method

A technology of excess sludge and cells, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long sludge residence time, complicated operation and management, and large pool volume. Achieve the effect of reducing digestion reaction time, improving dehydration performance, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

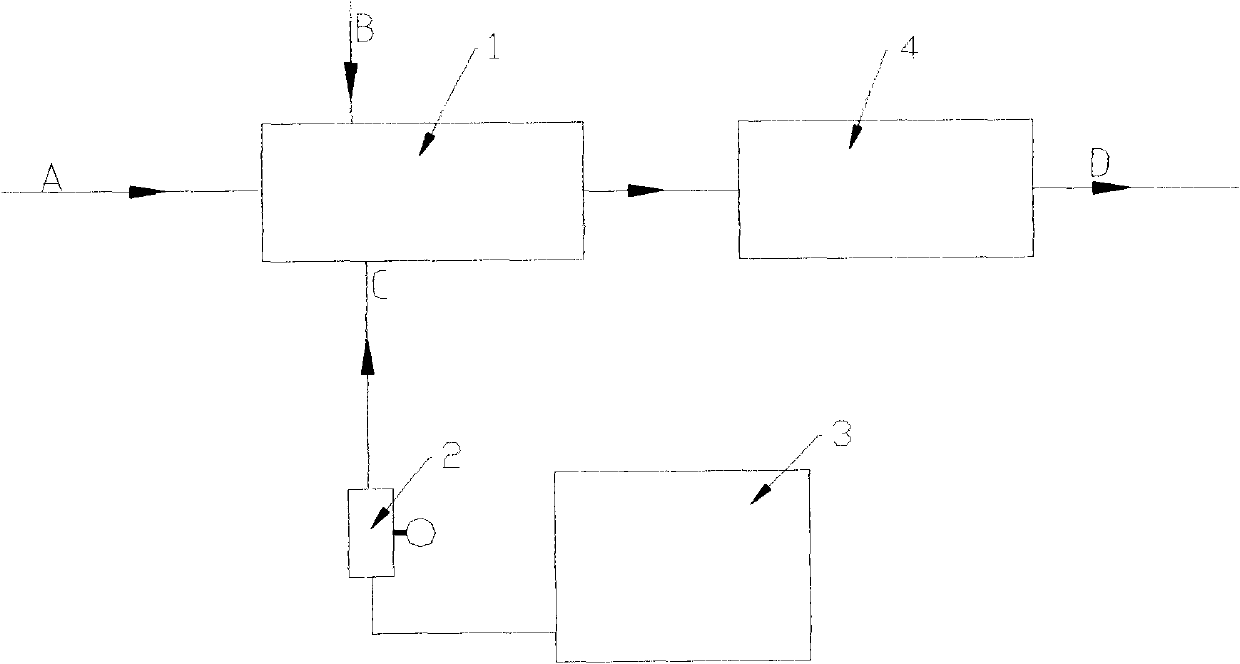

[0031] The embodiment of the present invention provides a system for breaking the cell wall of excess sewage. The mixer and the bead mill are in a split structure, and the sludge outlet end of the mixer is connected with the bead mill through a pipeline, such as figure 1 As shown, the system includes:

[0032] Mixer 1; Dosing pump 2; PH value adjustment device 3; Bead mill 4 and pipeline;

[0033] in,

[0034] A. Sludge inlet; B. Magnetic powder input inlet; C. PH adjustment inlet; D. Broken sludge outlet;

[0035] The mixer 1 is provided with a sludge inlet A and a magnetic powder feeding inlet B, and the sludge outlet of the mixer is connected with the bead mill 4 ; the mixer 1 is connected with the pH adjusting device 3 through the dosing pump 2 .

[0036] The method of using the above-mentioned system to deal with the broken cell wall of excess sludge is:

[0037] The remaining sludge with a water content of 95% enters the mixer, and the pH value is adjusted to 8 by the...

Embodiment 2

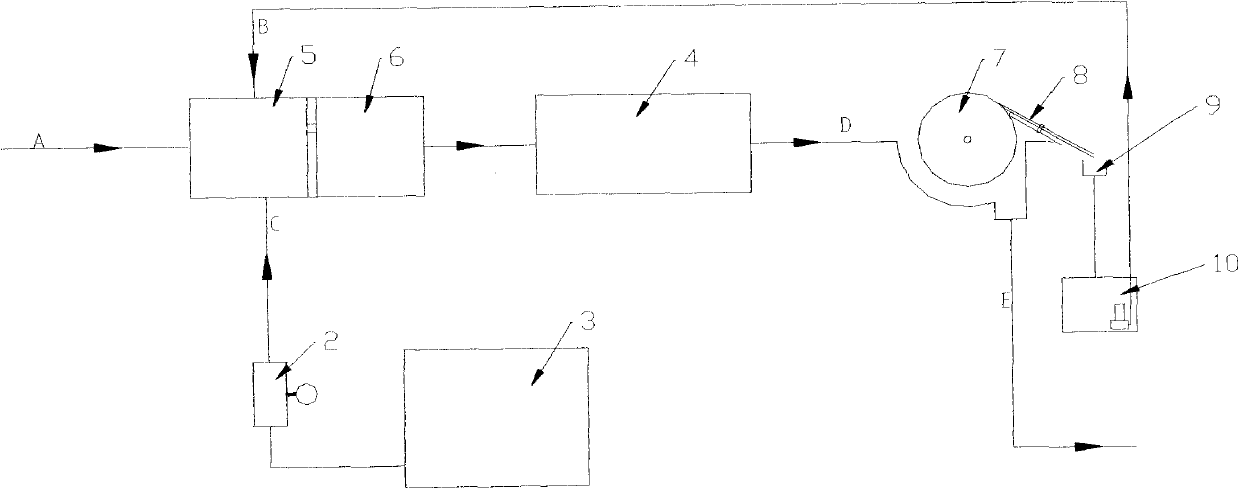

[0040] The embodiment of the present invention provides a system for breaking the cell wall of excess dirt. The magnetic powder feeding inlet is connected with the magnetic powder recovery circulation system. The magnetic powder recovery circulation system is composed of a magnetic separation device and a magnetic powder buffer box; the magnetic separation device consists of a magnetic drum and a slag scraping bar. It is composed of a slag unloading tank; the mixer and the bead mill are of a split structure, and the sludge outlet of the mixer is connected to the bead mill through a pipeline; there is an isolation plate inside the mixer, and the isolation plate divides the mixer into two parts. The sludge inlet side part of the mixer is mixer one, and the sludge outlet side part of the mixer is mixer two, and a communication port is provided on the isolation plate to connect mixer one and mixer two; the mixer is equipped with an agitator. Such as figure 2 As shown, the system ...

Embodiment 3

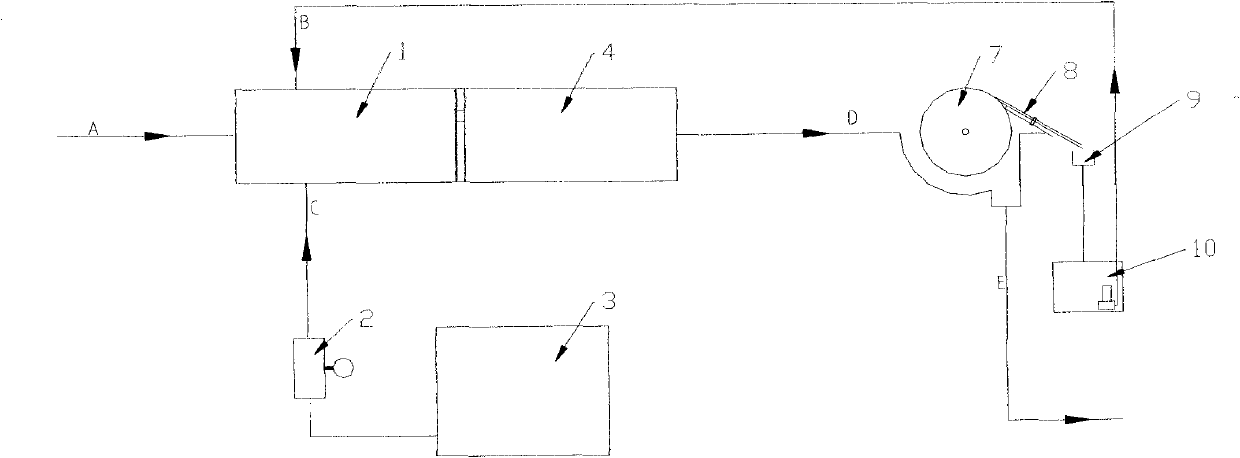

[0049] The embodiment of the present invention provides a system for breaking the cell wall of excess dirt. The magnetic powder feeding inlet is connected with the magnetic powder recovery circulation system. The magnetic powder recovery circulation system is composed of a magnetic separation device and a magnetic powder buffer box; the magnetic separation device consists of a magnetic drum and a slag scraping bar. It is composed of a slag unloading tank; the mixer and the bead mill are integrally structured, and the interior is divided into two parts by setting a partition plate, and a communication port is provided on the partition plate to connect the mixer and the bead mill. like image 3 As shown, the system includes:

[0050] Mixer 1; dosing pump 2; pH value adjustment device 3; bead mill 4; magnetic drum 7; slag scraping bar 8; slag discharge tank 9; magnetic powder buffer box 10 and pipeline;

[0051] in,

[0052] A. Sludge import; B. Magnetic powder input inlet; C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com