Rubber peptizer intermediate 2,2'-dinitro-diphenyl disulfide and preparation method thereof

A technology of dinitrodiphenyl disulfide and rubber peptizer, applied in the field of chemical additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

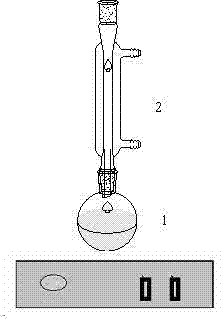

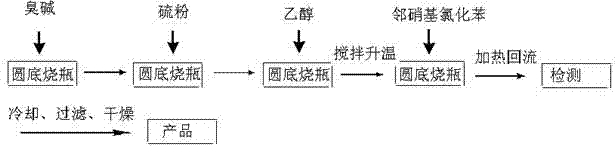

Method used

Image

Examples

Embodiment 1

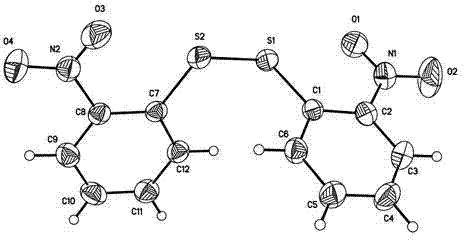

[0017] Example 1: Add 1.6g of industrial odorous alkali, 0.4g of sulfur powder, and 5g of ethanol into the reaction flask, and stir on a magnetic stirrer. After the temperature rises to 53°C, add 4g of o-nitrochlorobenzene, a black solution is formed, and heat Reflux, react for 4.5h, a yellow solid is formed, cool, filter with suction, dry, and the yield is 95%. The obtained rubber peptizer intermediate compound 2,2'-dinitrodiphenyl disulfide has a yellow solid appearance and a melting point of 298-300°C. The structural formula is as follows:

[0018] .

[0019] The nuclear magnetic data of gained product is as follows:

[0020] 1 H NMR (400MHz, CDCl 3, ppm), δ=8.35-8.32 (m, 2H), 7.86-7.84 (m, 2H), 7.60-7.56 (m, 2H), 7.42-7.38 (m, 2H). 13 C NMR (CDCl 3 , 100M, ppm,): δ=146.06, 134.84, 134.45, 127.17, 126.95, 126.31.;

[0021] Infrared analysis is as follows: IR(KBr, cm -1 ):3413, 1588, 1513, 1338, 1104, 734, 710, 677;

[0022] It can be seen from the nuclear magn...

Embodiment 2

[0026] Example 2: Add 1.8g of industrial odorous alkali, 0.4g of sulfur powder, and 5g of ethanol into the reaction flask, and stir on a magnetic stirrer. After the temperature rises to 50°C, add 4g of o-nitrochlorobenzene, a black solution is formed, and heat Reflux, react for 4h, a yellow solid is formed, cool, filter with suction, dry, and the yield is 87%.

Embodiment 3

[0027] Example 3: Add 1.5g of industrial odorous alkali, 0.4g of sulfur powder, and 5g of ethanol into the reaction flask, and stir on a magnetic stirrer. After the temperature rises to 53°C, add 4g of o-nitrochlorobenzene, a black solution is formed, and heat Reflux, react for 4h, a yellow solid is formed, cool, filter with suction, dry, and the yield is 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com