Molded object, method of producing the same, sealed molded object, polymer, and optical information recording medium

A molding and recording layer technology, applied in optical recording/reproduction, optical recording carrier, information storage, etc., can solve problems such as slow progress and achieve high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

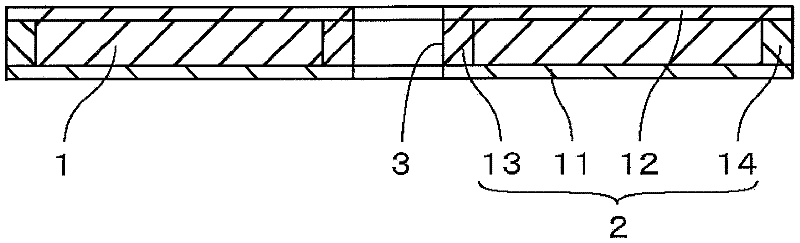

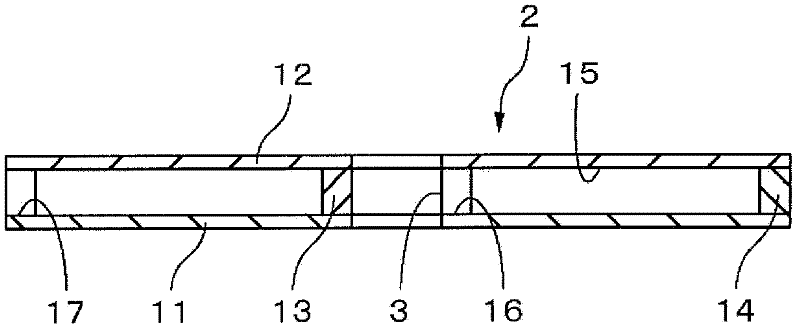

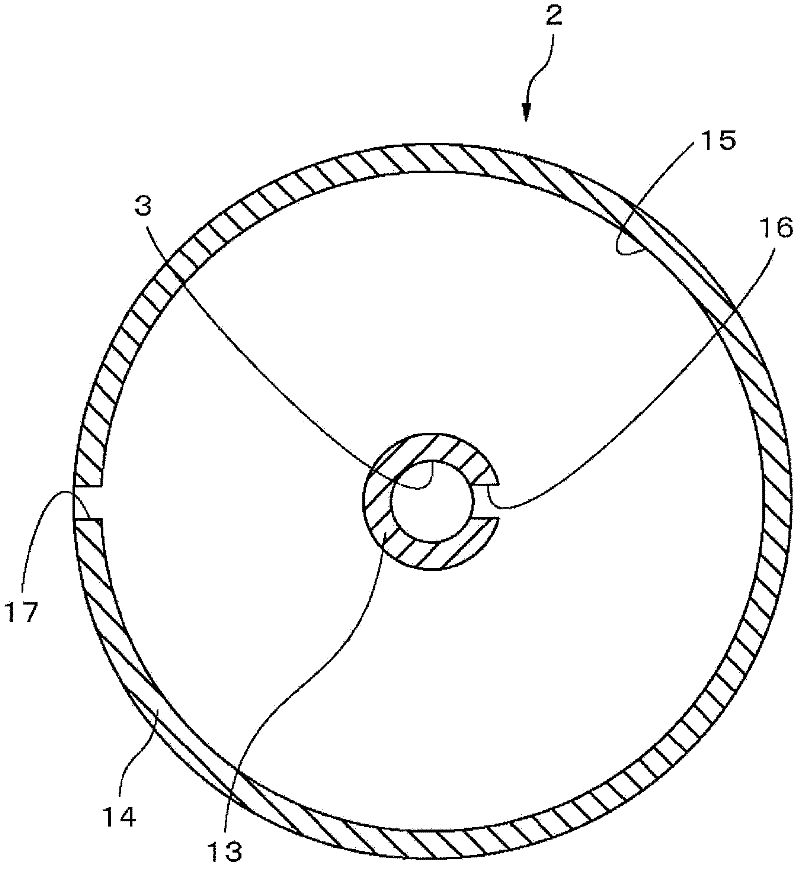

[0022] 1. First Embodiment (Example of Molded Article and Manufacturing Method Thereof)

no. 2 approach

[0023] 2. Second Embodiment (Example of Optical Information Recording Medium and Manufacturing Method Thereof)

[0024] [1. First Embodiment]

[0025] (molding)

[0026] The molding is obtained by curing a curable composition comprising a silicon analogue having one or more epoxy groups and an alpha-hydroxy acid. Specifically, the molded article is a polymer obtained by polymerizing a silicon analog having one or more epoxy groups using protons derived from an α-hydroxy acid as an initiator. The polymerization is ring-opening polymerization in which the epoxy group of the silicon analog is ring-opened and polymerized. Preferably, the curable composition is a thermosetting composition to be cured by a thermal reaction. Here, the thermal reaction also includes a reaction that proceeds spontaneously in an environment at a temperature around room temperature. Near room temperature means a temperature range from 10°C to 40°C.

[0027] Also, the curable composition may be fille...

Embodiment 1-1 to 1-5

[0129] As shown in Table 2, epoxy-siloxane compound A as a silicone derivative and DL-lactic acid as a carboxylic acid are combined in a mass ratio of 10:1 to 60:1 to make compatibilized, Thus a thermosetting composition was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com