Completion reoperation blowout control tail tube valve

A technology of blowout prevention and tailpipe, which is applied in the direction of wellbore/well valve device, flushing wellbore, wellbore/well parts, etc., which can solve the problem of clogging of the inner hole of the tubing well bottom, difficulty in delivering pluggers, and long operating cycle. Long-term problems, to achieve the effect of reducing operating costs, eliminating potential damage and safety hazards of operations, and convenient on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

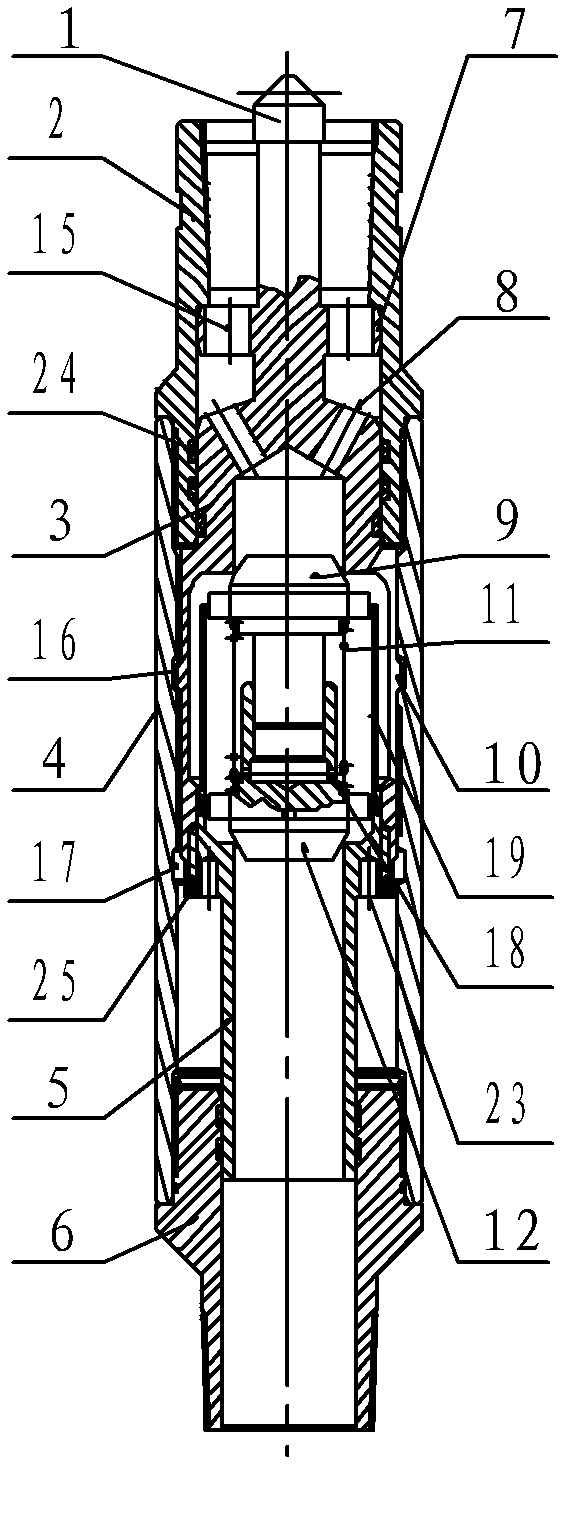

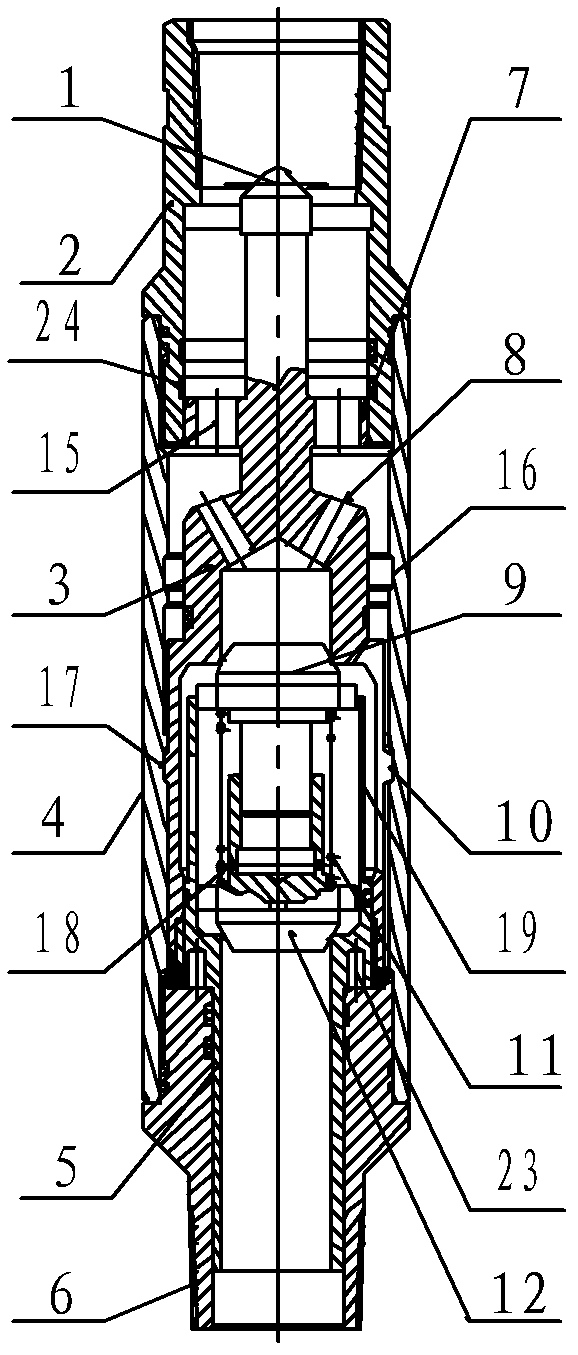

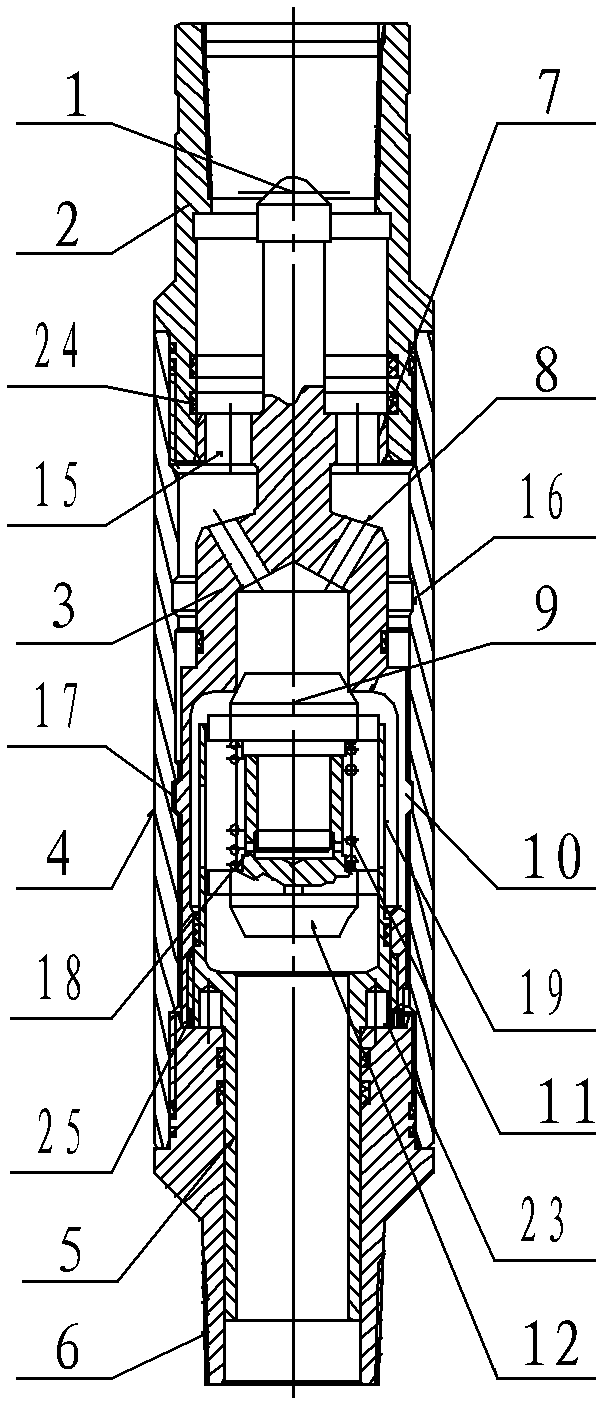

[0024] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0025] Such as figure 1 , Figure 5 , Image 6 As shown, the valve is connected with the upper joint 2 and the lower joint 6 respectively in the inner holes of the upper and lower ends of the coupling 4 to form the valve body shell, and the inner hole of the upper joint 2 is provided with a cone connected to the tail of the oil pipe. Shaped connecting screw hole, the lower end of the lower joint 6 is provided with a tapered threaded joint connected to the outer periphery of the screen pipe, and the inner hole of the valve is formed under the tapered connecting screw hole, the lower end surface of the upper joint 2 and the lower end surface of the lower joint 6. The three-stage positioning step through hole on the upper end surface, the inner hole of the valve body and the inner hole wall of the coupling 4 are provided with an upper limit groove 16 and a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com