Combustion device for tangentially fired boiler and ultralow NOx combustion method employing same

A technology for combustion devices and boilers, which is applied in the direction of combustion methods, burners for burning powder fuel, burners, etc., and can solve problems such as inability to strengthen the NO reduction process, low NO reduction temperature, and incomplete combustion of pulverized coal, so as to avoid furnace Internal negative problems, reducing NOX concentration, reducing the effect of initial investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

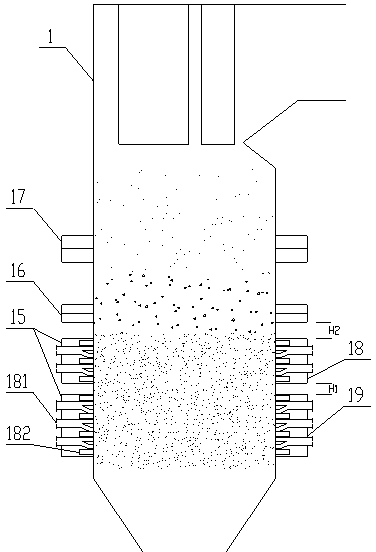

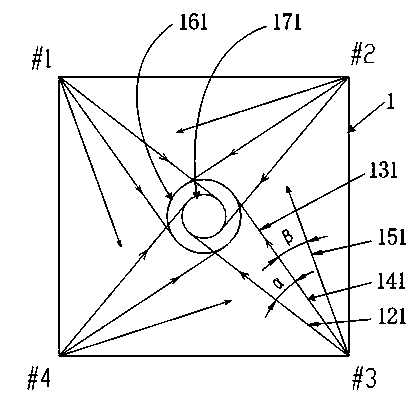

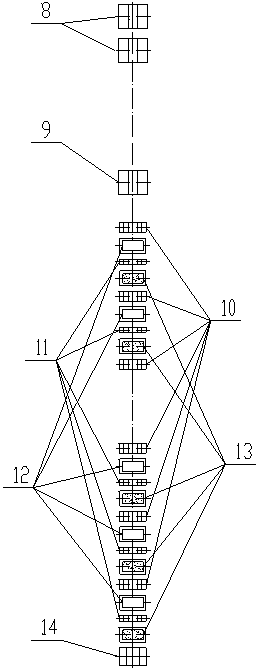

[0030] combine figure 1 , figure 2 , image 3 Describe this embodiment mode, this embodiment adopts the primary air burner with upper concentration and lower lightness with intermediate secondary air. The burner 16 and the main burner 15, the high burner 17 corresponds to the burnout zone, the low burner 16 corresponds to the reduction zone, and the main burner 15 corresponds to the main combustion zone. The furnace is divided along the height direction, thereby realizing the depth along the furnace height direction. Air classification, optimal design of excess air coefficient in each area.

[0031] The main burner 15 comprises a thick and light primary air pulverized coal burner 181 and a secondary air pulverized coal burner 182 arranged on the primary air pulverized coal burner 181, and the secondary air pulverized coal burner 182 corresponds to the secondary air spout 10, so The primary air pulverized coal burner 181 is a bifurcated pipe, and the front end of the bifurc...

Embodiment 2

[0043] combine figure 1 , figure 2 , Figure 4 Describe this embodiment, this embodiment adopts the primary air burner with upper light and lower concentration of secondary air in the middle, and other arrangement methods are the same as in embodiment 1.

Embodiment 3

[0045] combine figure 1 , figure 2 , Figure 5 To illustrate this embodiment, this embodiment adopts the combined arrangement of the upper-concentrated and lower-diluted primary air burner with the middle secondary air and the upper-diluted and lower-concentrated primary air burner. The combined arrangement method is not limited to the illustration, and other arrangement methods Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com