Environmentally-friendly compound gas-burning three-dimensional porous infrared radiation device

A technology of gas combustion and infrared radiation, which is applied to gas fuel burners, burners, combustion methods, etc., and can solve problems such as unseen products and literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

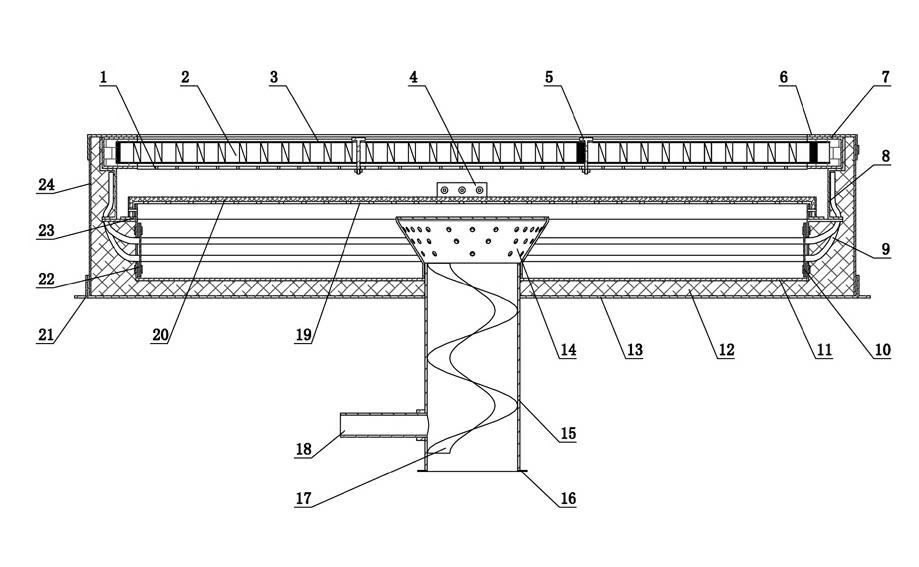

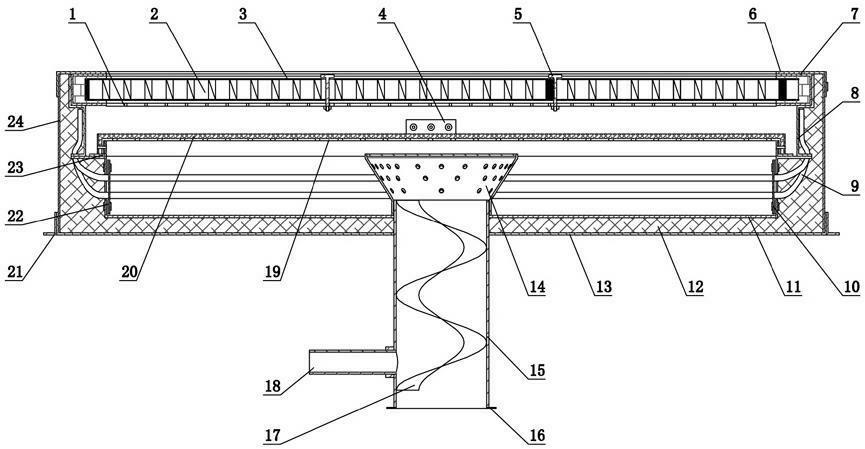

[0023] combine figure 1 As shown, an environment-friendly compound gas combustion stereo porous infrared radiation device of the present invention is realized by adopting the following technical solutions:

[0024]An environment-friendly compound gas combustion three-dimensional porous infrared radiation device includes a support bar 1, a porous radiation plate 2, a composite coating 3, an igniter 4, a fixing nail 5, a fixing frame 7, an annular cavity wall 8, a heat exchange tube 9, a Heat pipe fixing piece 10, cavity box 11, insulation layer 12, injection head 14, injection tube 15, flange 16, spiral sheet 17, fuel inlet pipe 18, punching plate 19, combustion carrier 20, sealant 22 , the fixing base 23, the lower cover 13, the upper cover 6, the outer frame 24 and the mounting member 21. The ejector pipe 15 is provided with a helical piece 17; one end of the ejector pipe 15 is provided with a flange 16 for connecting the fan and peripheral control elements; 14 is fixedly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com