Evaporating plant in refrigerating system

An evaporating device and refrigeration system technology, applied in the field of refrigeration systems and evaporating devices, can solve the problems of reducing the heat transfer efficiency outside the tube, easy fouling after long-term use, and thin baffle structure, so as to increase the degree of automation and reduce the evaporator. Risk, effect in favor of deposition and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

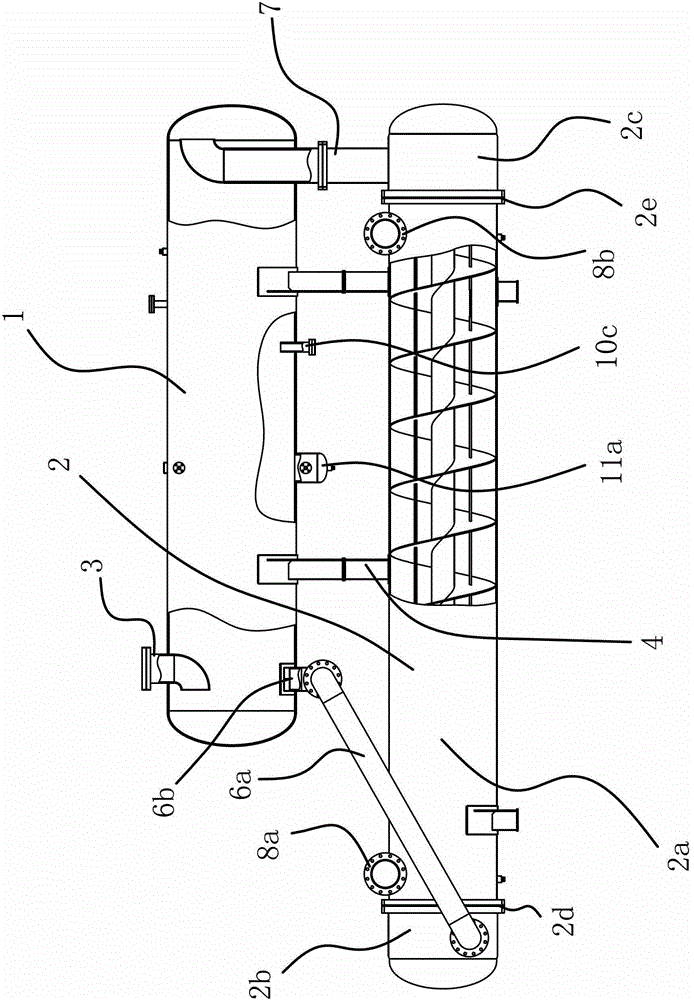

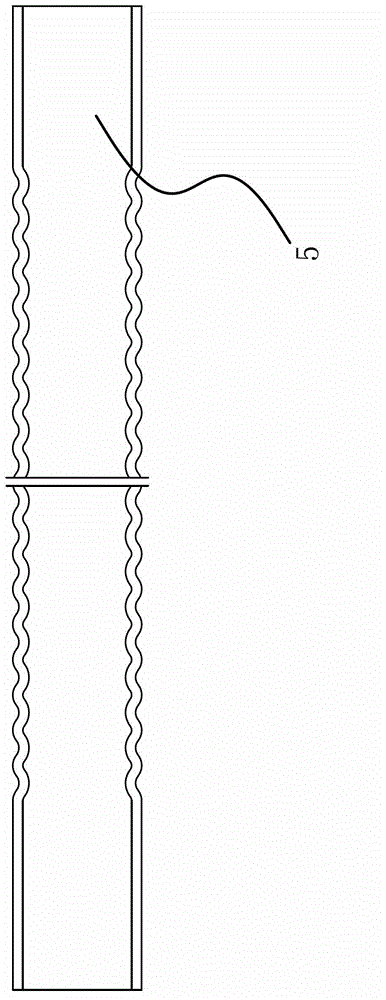

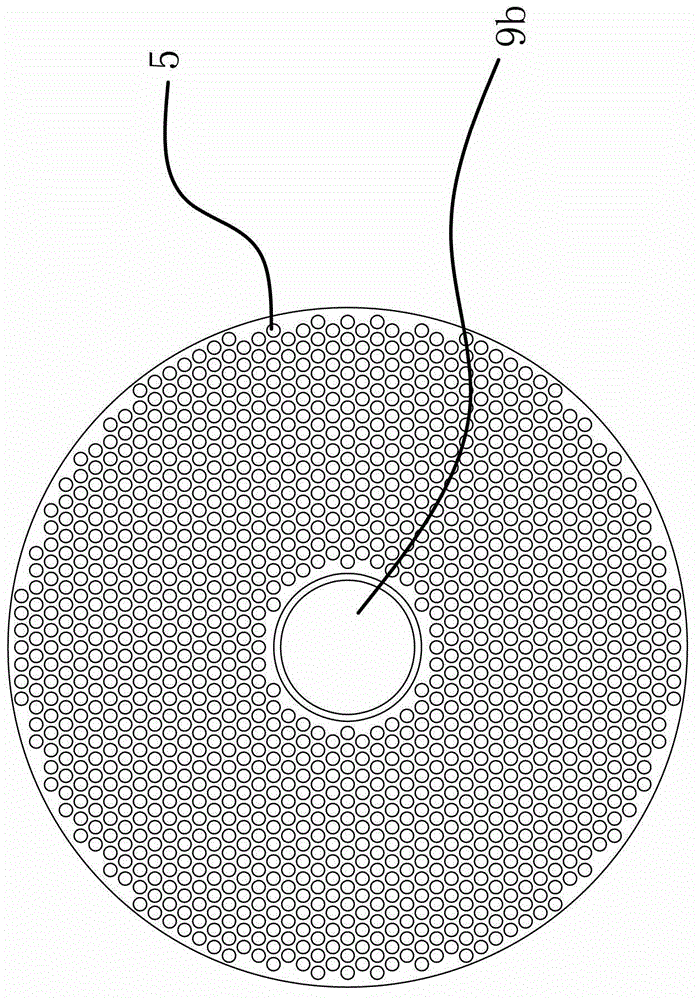

[0035] like Figures 1 to 7 shown, an evaporation device in a refrigeration system, such as figure 1 As shown, it includes a separator 1 and an evaporator 2 with a return pipe 3, and the refrigeration system also includes a compressor and a condenser. The compressor is connected with the return pipe 3, and the separator 1 is located above the evaporator 2. Seat 4 is fixed. The cooling medium used in this refrigeration system is ammonia liquid, and the cooling medium is brine. There are several heat exchange tubes 5 in the evaporator 2, such as figure 2 , image 3 As shown, the heat exchange tube 5 is a corrugated tube. The uneven inner surface increases the disturbance of the cooling medium in the heat exchange tube 5, and increases the heat transfer coefficient of the cooling medium in the heat exchange tube 5; at the same time, the corrugated tube or the cross-corrugated tube increases the wall of the heat exchange tube 5. The surface area increases the efficiency of h...

Embodiment 2

[0045] The content in the second embodiment is roughly the same as that in the first embodiment, except that the heat exchange tube 5 in the first embodiment is a corrugated tube; Figure 8 As shown, the heat exchange tube 5 in the second embodiment is a cross-ribbed tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com