Multi-rotor joint vibration mode balancing method for single support shafting steam turbine generator unit

A turbo-generator set, vibration-shape balancing technology, applied in the static/dynamic balance test, machine/structural component test, measuring device, etc., can solve problems such as large aggravation interval, impossibility of implementation, unstable power frequency vibration, etc. , to achieve the effect of improving balance efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is a multi-rotor joint mode balance method for a single-support shafting turbogenerator set, which will be described in detail below (the rated speed is 3000r / min as an example):

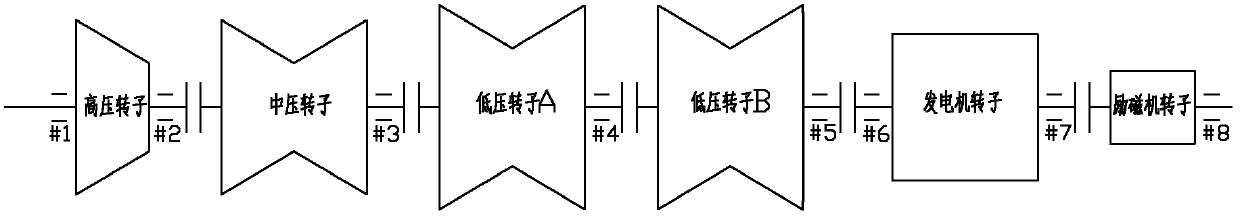

[0021] The shaft system of the steam turbine unit consists of a high-pressure rotor, a medium-pressure rotor, two low-pressure rotors, a generator rotor and an exciter rotor. The rotors are connected by rigid couplings. The high-pressure rotor is double-supported, and the medium-pressure rotor and two The low-pressure rotors are all single-supported, and No. 1-5 bearings are arranged between the above-mentioned four rotors. The rotor of the generator and the exciter is a three-supported structure, and the shafting arrangement is as follows: figure 1 shown.

[0022] (1) Rotor vibration vector calculation

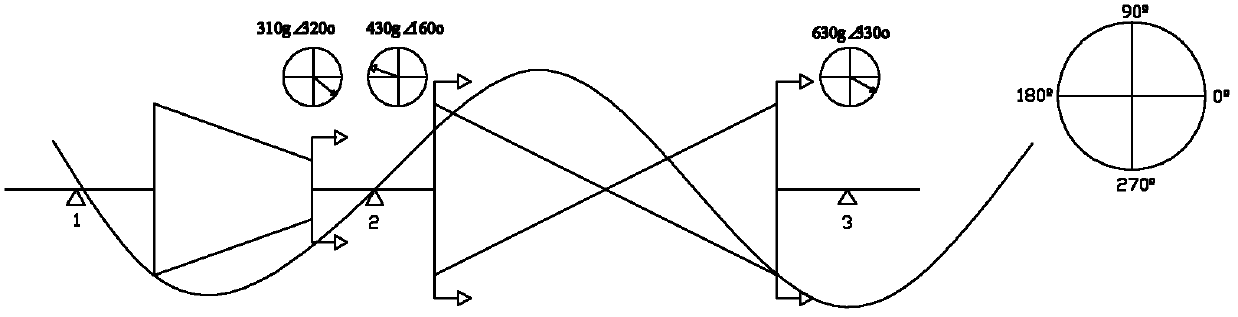

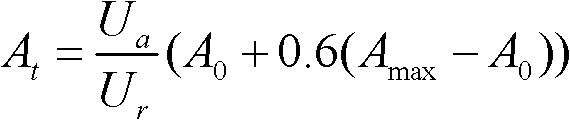

[0023] When the steam turbine unit is running at a rated speed of 3000r / min, according to the vibration test system, the power frequency shaft vibration vector A of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com