Test method for evaluating actual risk of alkali-aggregate reaction of hydraulic concrete

A hydraulic concrete and test method technology, applied in the direction of material inspection products, etc., can solve the problems of the decrease and change of alkali content in concrete, and the small expansion rate of test pieces, so as to achieve the effect of reducing the precipitation of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

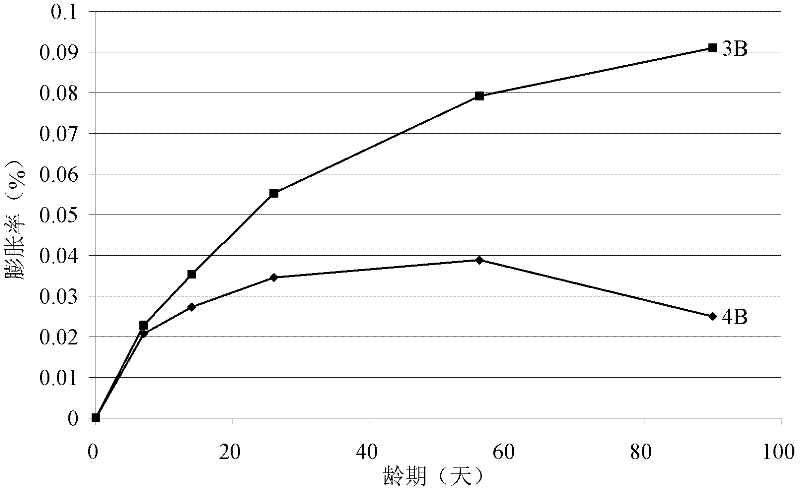

[0048] Example 1: A certain dam concrete mix ratio is used, see Table 2. The mix ratio of No. 4B is the mix ratio of four-grade normal dam concrete, and the maximum particle size of the aggregate is 150mm. The mix ratio numbered 3B is a three-graded normal dam concrete mix ratio, and the maximum particle size of the aggregate is 80mm.

[0049] Table 2 Dam concrete mix ratio (kg / m 3 )

[0050]

[0051] Concrete is mixed with a self-falling mixer according to the mix ratio given in Table 2, and the equivalent Na of the cement is reduced by adding NaOH 2 Adjust the O content to 1.25%, pass the evenly stirred concrete through a 40mm sieve until no slurry or fine particles fall from the sieve within 1min. Pour the wet sieved concrete under the sieve into the 100mm×100mm×515mm prismatic cast iron test mold with the measuring head installed, and ensure that the concrete around the measuring head is squeezed and compacted, and then the test mold is placed on the vibrating table ...

Embodiment 2

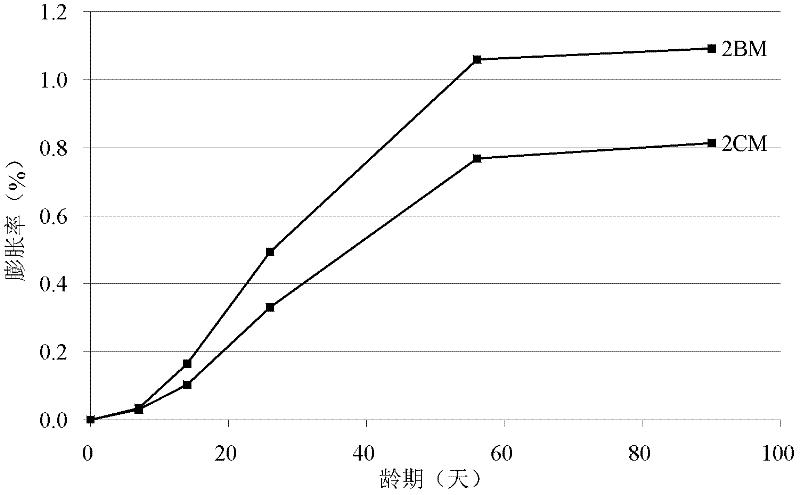

[0053] Example 2: See Table 3 for the mix ratio of anti-scouring concrete for a flood discharge tunnel of a hydropower project. The mix ratio of the number "2CM" is the mix ratio of the secondary normal anti-scouring concrete, and the maximum particle size of the aggregate is 40mm. The mix ratio of the code "2BM" is the mix ratio of the secondary pumped anti-scouring concrete, and the maximum particle size of the aggregate is 40mm.

[0054] Table 3 The mix ratio of anti-scouring concrete for a spillway tunnel (kg / m 3 )

[0055]

[0056] Concrete is mixed with a forced mixer according to the mix ratio given in Table 3, and the equivalent Na of cement is reduced by adding NaOH 2 The O content was adjusted to 1.25%, and the uniformly stirred concrete was poured into a 100mm×100mm×515mm cast iron test mold with a measuring head installed, and the rest of the operations were the same as in Example 1. "2CM" and "2BM" mix proportion measured expansion rate of each age is attach...

Embodiment 3

[0058] Embodiment 3: Except that the surface of the test piece is not wrapped with self-adhesive aluminum foil, the rest is the same as that of Embodiment 2.

[0059] Compared with Example 2, as a result, the measured expansion rates of "2CM" and "2BM" at the age of 90 days were reduced by 0.28% and 0.35% respectively, and white alkaline substances were precipitated on the surface of the test piece.

[0060] This shows that wrapping aluminum foil can effectively avoid the precipitation of alkali inside the specimen to the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com