Electrostatic attenuation time testing device

A decay time, testing device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

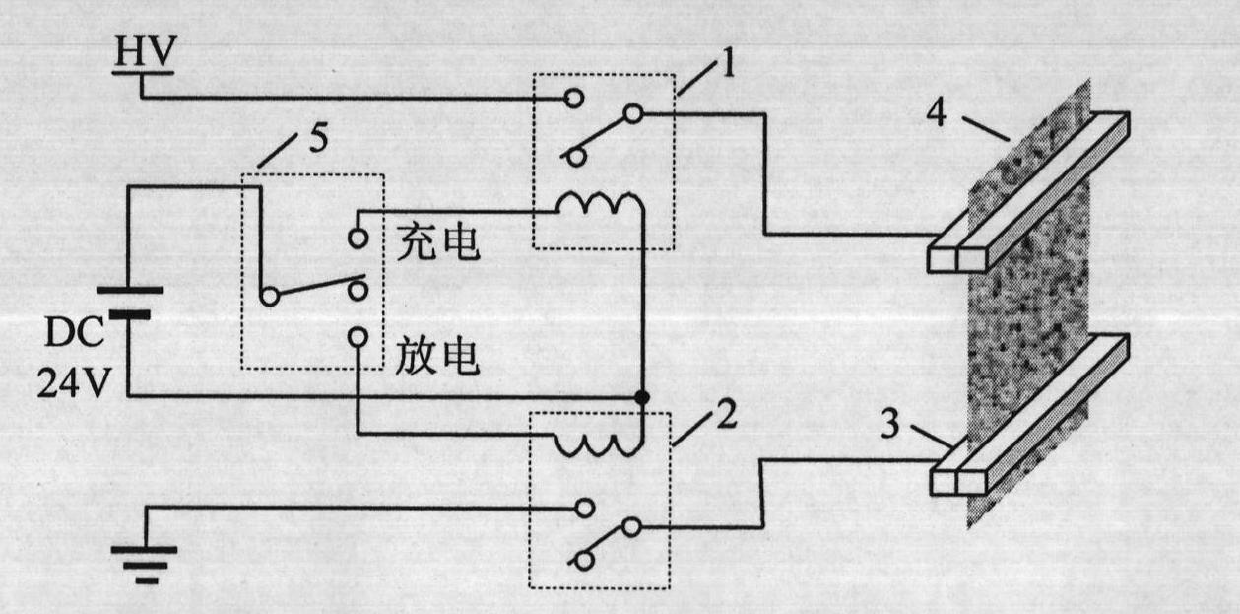

[0016] figure 1 It is the schematic diagram of charge-discharge control circuit when testing samples: 1-vacuum high-voltage switch 1; 2-vacuum high-voltage switch 2; 3-electrode and sample fixture; 4-sample schematic diagram; 5-low voltage control charge-discharge switch.

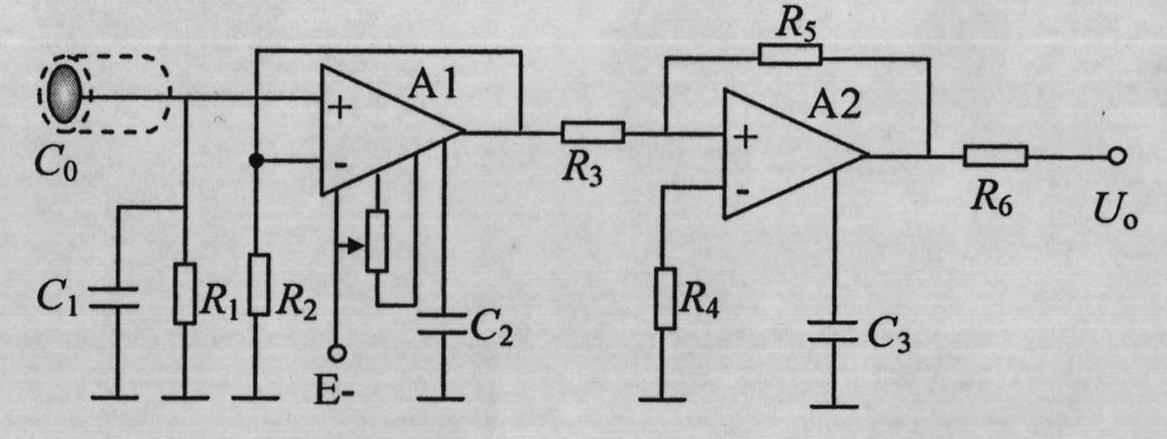

[0017] figure 2 It is a non-contact active sensor electrical schematic diagram: C 0 Indicates the equivalent capacitance of the input probe to the ground; A1 is the emitter follower, A2 is the non-inverting amplifier; R 1 >1GΩ, R 2 >3MΩ, used for zero drift suppression; the circuit is also equipped with zero adjustment and zero reset buttons, which are used to reset the circuit before testing.

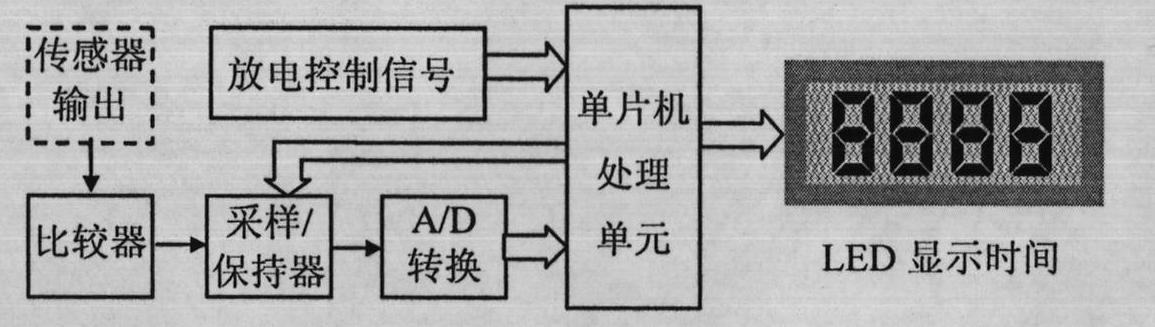

[0018] image 3 It is the principle block diagram of the decay time timing device of the present invention: the discharge control signal is used as the trigger signal to make the single chip microcomputer start counting, and the time is displayed by the LED; at the same time, the decay voltage on the sample is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com