Hydraulic drive device of hydraulic operating machine

一种液压工程机械、驱动装置的技术,应用在传动装置控制、液体变容式机械、机械设备等方向,能够解决过滤器的网眼易堵住等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

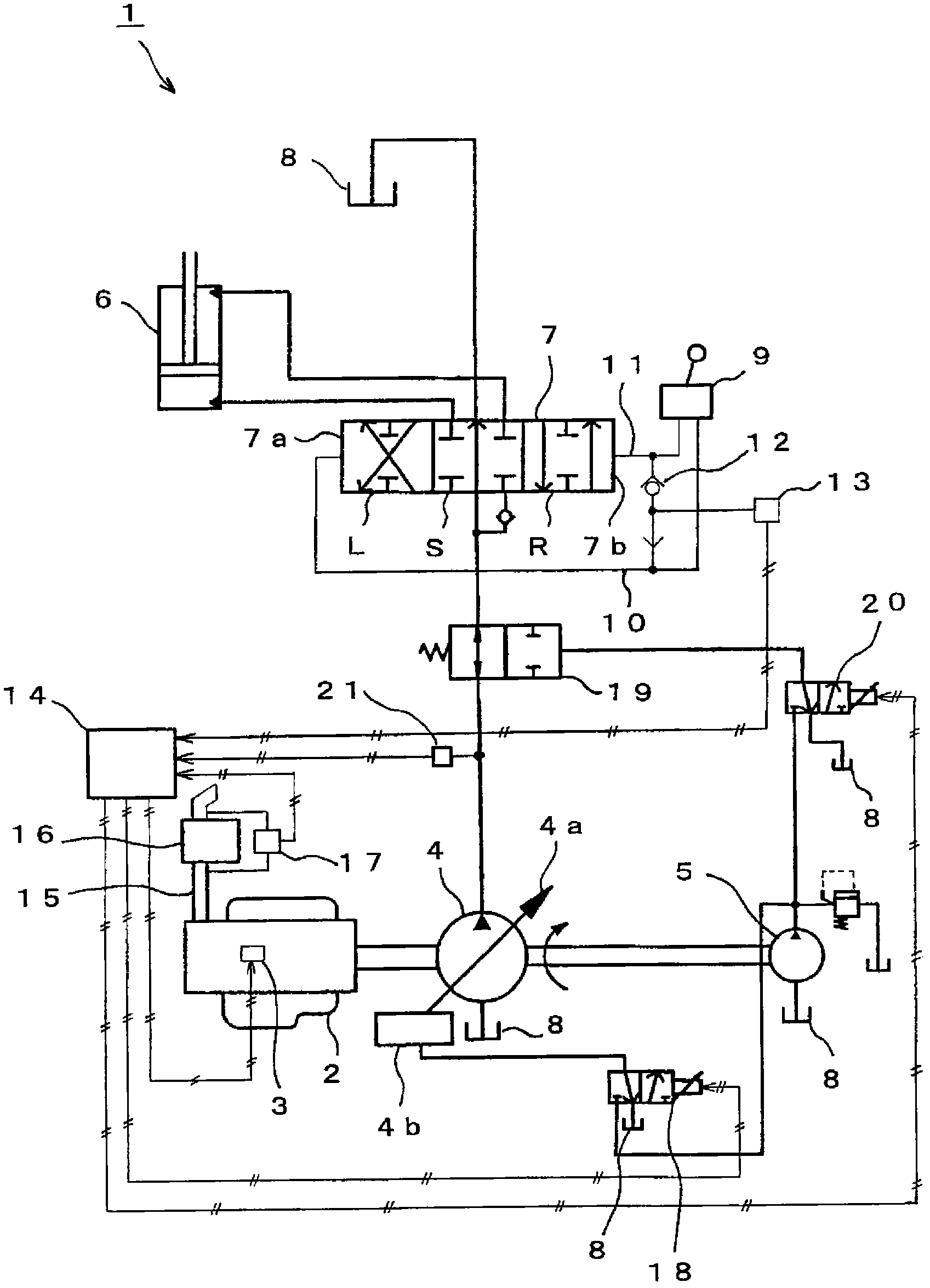

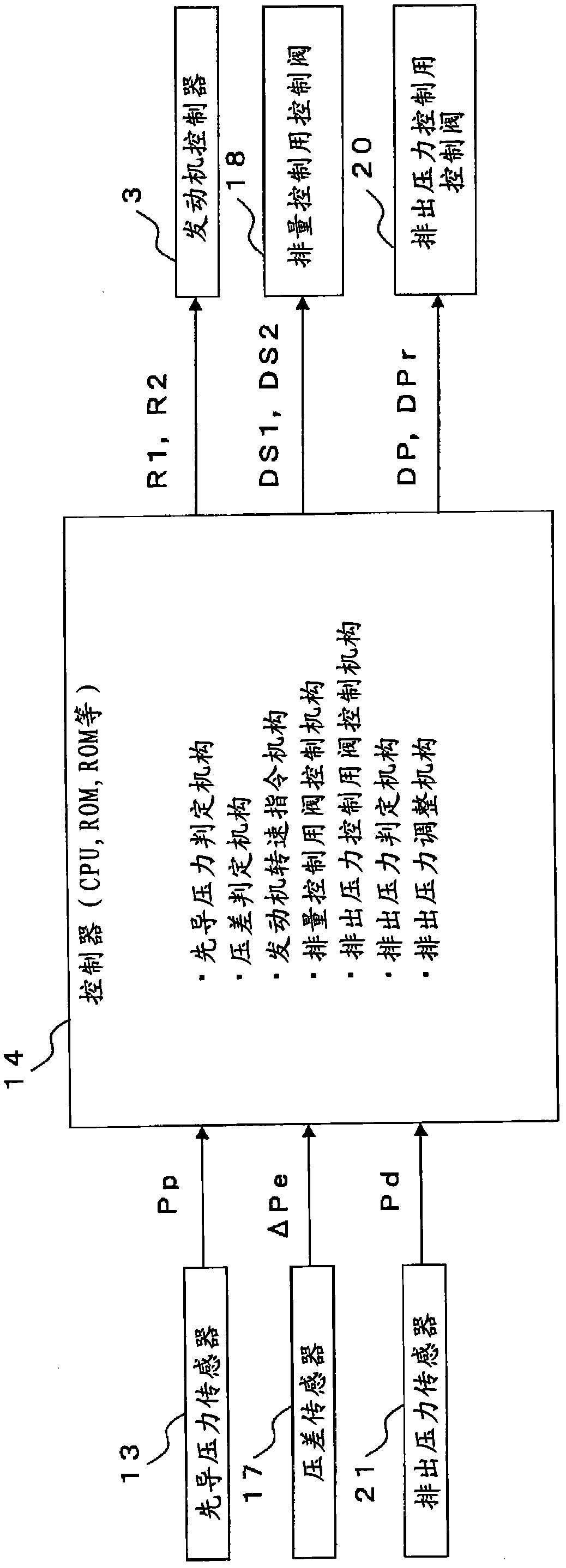

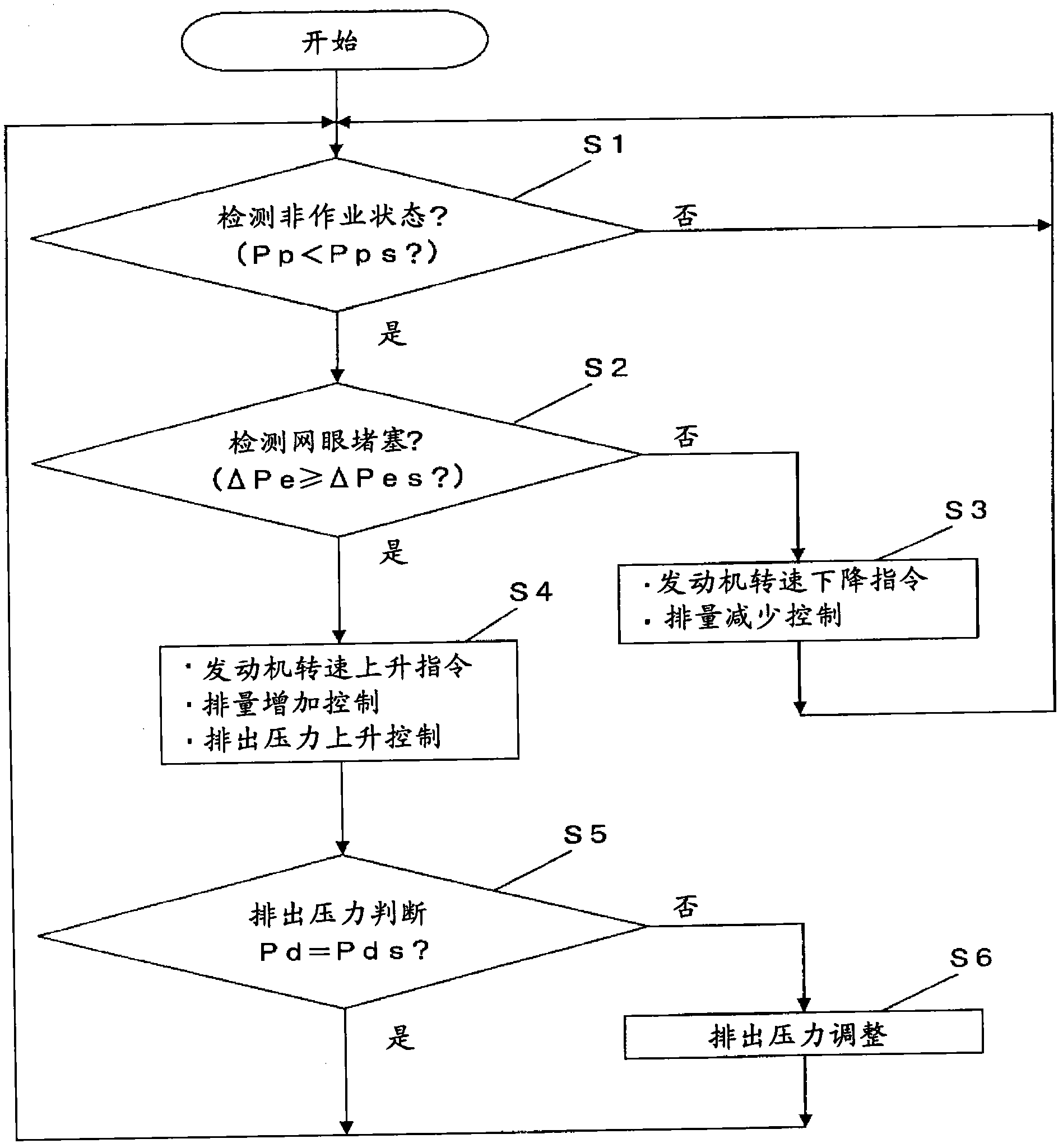

[0026] use figure 1 The hydraulic drive device of the hydraulic construction machine according to the first embodiment of the present invention will be described. figure 1 This is a hydraulic circuit diagram showing the configuration of the hydraulic drive device of the hydraulic construction machine according to the first embodiment of the present invention. figure 2 to represent the extraction figure 1 Block diagram of the electrical system of the hydraulic drive shown. image 3 to express figure 2 A flowchart showing the flow of actions in the controller.

[0027] like figure 1 As shown, the hydraulic drive device 1 of the hydraulic construction machine according to the first embodiment includes: an engine 2 (eg, a diesel engine) whose fuel injection amount is electronically controlled by an engine controller 3; A displacement type hydraulic pump 4 and a pilot pump 5 (fixed displacement type pump); and a hydraulic actuator 6 driven by hydraulic oil discharged from th...

no. 2 approach

[0061] use Figure 4 A hydraulic drive device of a hydraulic construction machine according to a second embodiment of the present invention will be described. Figure 4 It is a hydraulic circuit diagram which shows the structure of the hydraulic drive apparatus of the hydraulic construction machine concerning 2nd Embodiment of this invention.

[0062] like Figure 4 As shown, in the hydraulic drive device 30 of the second embodiment, the variable restrictor 19 is provided downstream of the actuator control control valve 7 on the flow path of the hydraulic oil discharged from the variable displacement hydraulic pump 4 side. The other configuration of the hydraulic drive device 30 is the same as that of the hydraulic drive device 1 of the first embodiment.

[0063] However, in the hydraulic drive device 30, the variable restrictor 19 adjusts the discharge passage of the hydraulic pressure from the actuator control control valve 7 to the hydraulic oil tank 8, even when the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com