Method for producing tea

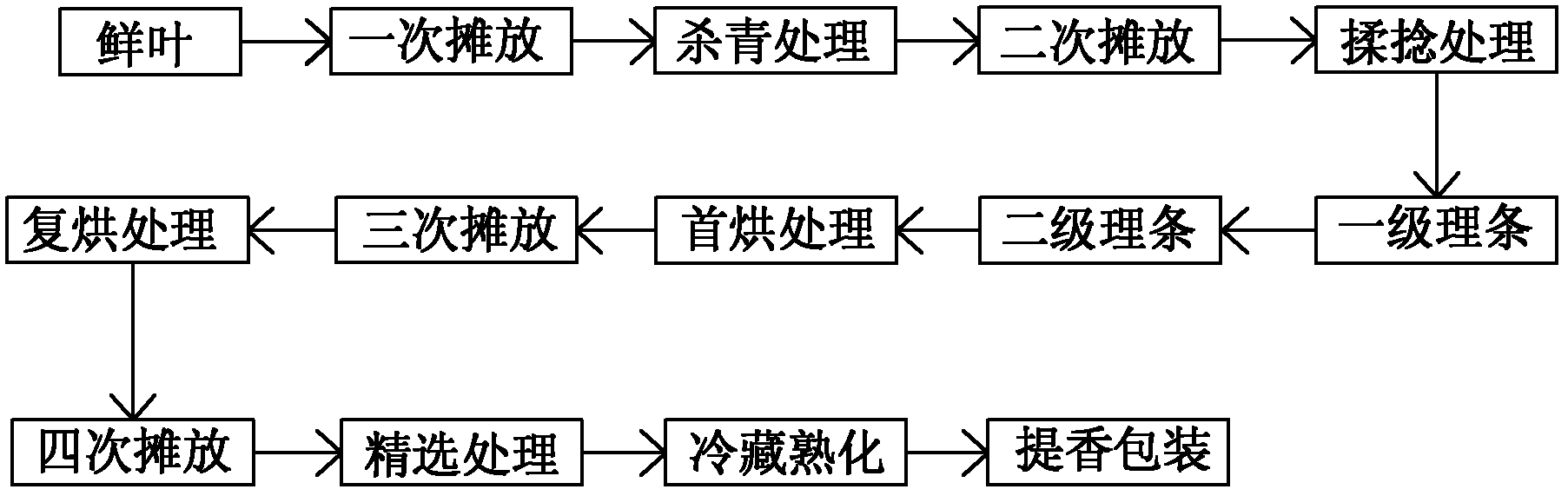

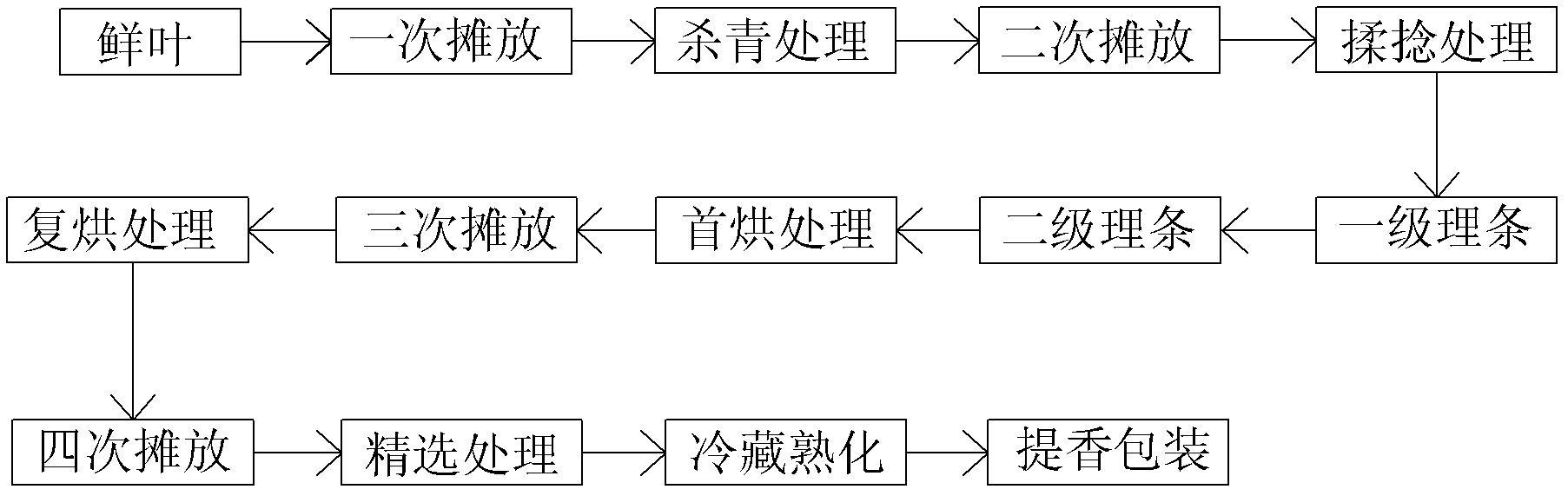

A production method and tea technology, which is applied in the field of tea production, can solve the problems of tea leaves with no obvious floral fragrance, tea leaves with loose shape, and tea leaves that are easy to be crushed, and achieve the effects of improving the purity of taste, strong floral fragrance, and promoting aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Spread 10kg of the selected fresh leaves in grades on the green storage racks in the silo and let them stand naturally for 4 hours until the fresh leaves wither moderately, the leaf color begins to turn dark and the green grass gas dissipates, and a slight green fragrance appears; The fresh leaves are sent to the electric roller de-enzyming machine for de-enzyme treatment, the de-enzyme temperature is controlled at 110°C, and the de-enzyme time is 3 minutes; the finished de-enzyme leaves are placed on a cooling mat for 20 minutes, so that the de-enzyme leaves are cooled and revived; After the leaves are cooled, put them into a special kneading machine to gently knead the tea leaves. The kneading time is controlled to be 5 minutes; The stripping temperature is 60°C; after the first stripping is finished, put the tea leaves into the second stripping machine for tea stripping treatment again, the control stripping time is 1min, and the stripping temperature is 50°C; Put it...

Embodiment 2

[0030] Put 10kg of selected fresh leaves on the green storage shelf in the green storage room and spread them naturally for 7 hours, until the fresh leaves wither moderately, the leaf color begins to turn dark, the grass gas is lost, and the green fragrance is slightly visible; The fresh leaves are sent to the electric roller de-enzyming machine for de-enzyme treatment, the de-enzyme temperature is controlled at 100°C, and the de-enzyme time is 4 minutes; the finished de-enzyme leaves are placed on a cooling mat for 30 minutes to cool and revive the de-enzyme leaves; After the leaves are cooled, put them into a special kneading machine to gently knead the tea leaves. The kneading time is controlled to be 8 minutes; The stripping temperature is 50°C; after the first stripping is finished, put the tea leaves into the second stripping machine for tea stripping treatment again, the control stripping time is 2min, and the stripping temperature is 40°C; After finishing the stripping...

Embodiment 3

[0032]Spread 10kg of the selected fresh leaves in grades on the green storage rack in the silo and let them stand naturally for 6 hours until the fresh leaves wither moderately, the leaf color begins to turn dark and the green grass gas dissipates, and a slight green fragrance appears; The fresh leaves are sent to the electric roller de-enzyming machine for de-enzyme treatment, the de-enzyme temperature is controlled to be 105°C, and the de-enzyme time is 3.5 minutes; the finished de-enzyme leaves are placed on a cooling mat for 25 minutes, so that the de-enzyme leaves are cooled and recovered; After the green leaves are cooled, put it into a special kneading machine to gently knead the tea leaves, and the kneading time is controlled to be 7 minutes; the tea leaves after kneading are poured into the first kneading machine for kneading treatment, and the kneading time is controlled for 2.5 minutes. min, the stripping temperature is 55°C; after the first stripping is finished, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com