Liquid seasoning combiner and liquid seasoning

A technology of liquid seasoning and composition, applied in the field of liquid seasoning, which can solve the problems of limited application and achieve the effects of convenient use, long shelf life, and promotion of healthy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

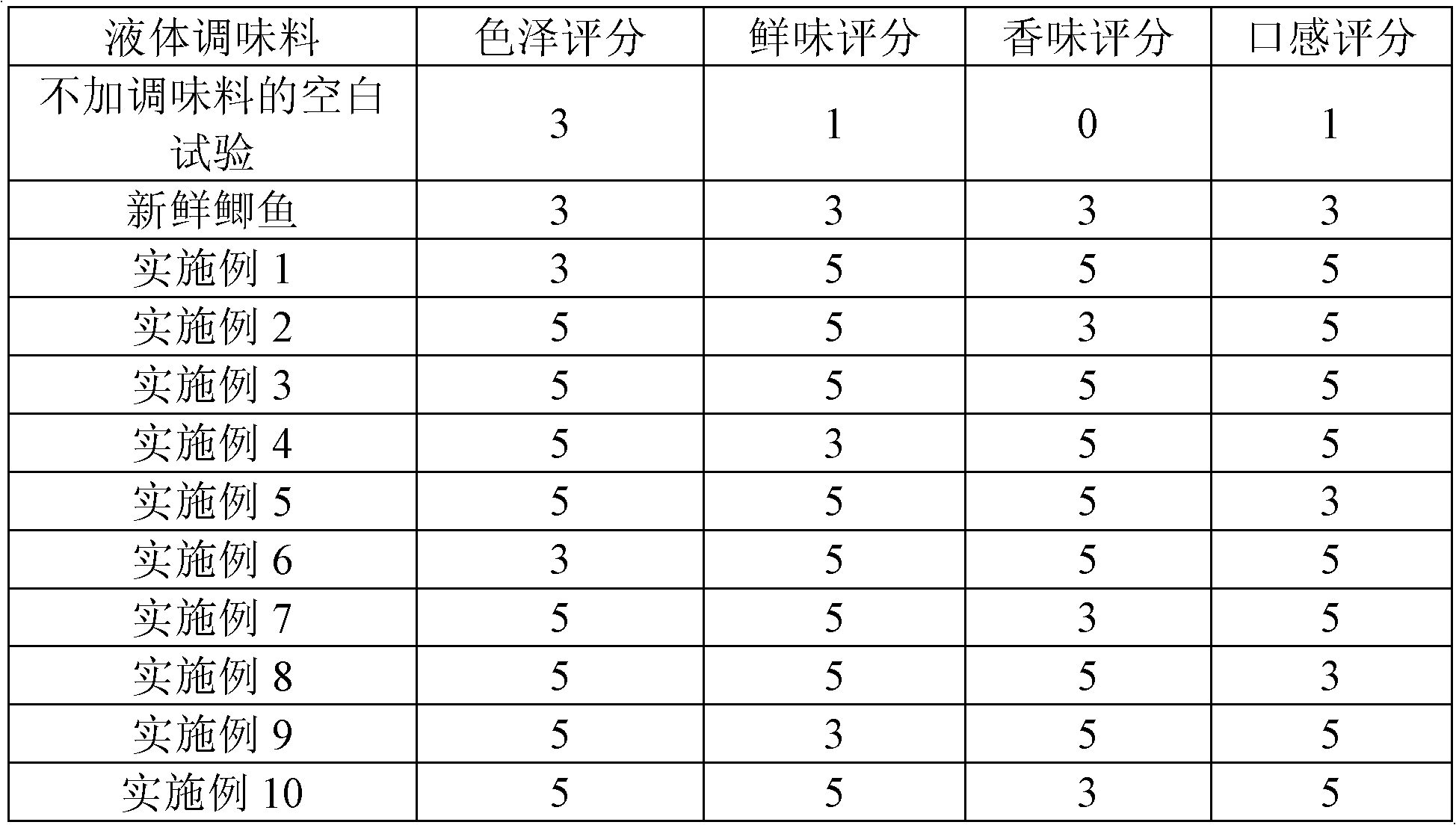

Examples

Embodiment 1

[0032] Prepare liquid seasoning of the present invention, it comprises the steps:

[0033]Mix 10.2wt% crucian carp extract with 4.4wt% thickener (xanthan gum), 1.6wt% sodium glutamate, 19.1wt% salt, 59.1wt% water, 0.1wt% disodium nucleotides, 0.1 wt% animal protein extract, 0.6wt% yeast extract, 0.1wt% spices (0.05wt% chives, 0.02wt% fennel, 0.03wt% ginger), 1.8wt% non-dairy creamer, 2.8wt% edible vegetable oil ( Soybean oil) and 0.1wt% emulsifier (propylene glycol fatty acid ester), put into the heating tank and stir and heat to 95°C, heat preservation and heating for 20 minutes; then cool to below 40°C, when the flow rate is 400L / h, the homogeneous pressure is After homogenization under the condition of 80MPa, it can be weighed and filled.

Embodiment 2

[0035] Prepare liquid seasoning of the present invention, it comprises the steps:

[0036] With 25.1wt% crucian carp extract and 2wt% thickener (1wt% gum arabic, 0.5wt% gelatin, 0.5wt% modified starch), 0.6wt% sodium glutamate, 13.2wt% salt, 59.1wt% water, put Put it into the heating tank, stir and heat to 80°C, keep warm and heat for 40 minutes; then cool to below 40°C, homogenize under the condition of flow rate of 400L / h and homogenization pressure of 80MPa, weigh and fill. .

Embodiment 3

[0038] Prepare liquid seasoning of the present invention, it comprises the steps:

[0039] 18.6wt% crucian carp extract and 2wt% thickener (1wt% xanthan gum, 0.5wt% carrageenan, 0.5wt% agar), 0.7wt% sodium glutamate, 13.2wt% salt, 59.1wt% water, 0.2wt% animal protein extract, 0.4wt% yeast extract, 0.3wt% spices (0.15wt% cinnamon, 0.1wt% garlic, 0.05wt% onion), 2wt% white sugar, 1.8wt% non-dairy creamer, 1.5wt% % edible vegetable oil (rapeseed oil) and 0.2wt% emulsifier (polyglycerol fatty acid ester), put into a heating tank, stir and heat to 85°C, keep warm and heat for 35 minutes; then cool to below 40°C, at a flow rate of 500L / h, after homogenization under the condition of homogenization pressure of 60MPa, weigh and fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com