Method for in situ generating inorganic nano particles-polyelectrolyte hybrid membrane

A technology of inorganic nanoparticles and polyelectrolytes, applied in the field of membrane separation, can solve the problems of mechanical strength and resistance to organic solvents to be further improved, and achieve the effects of convenient operation, high separation performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

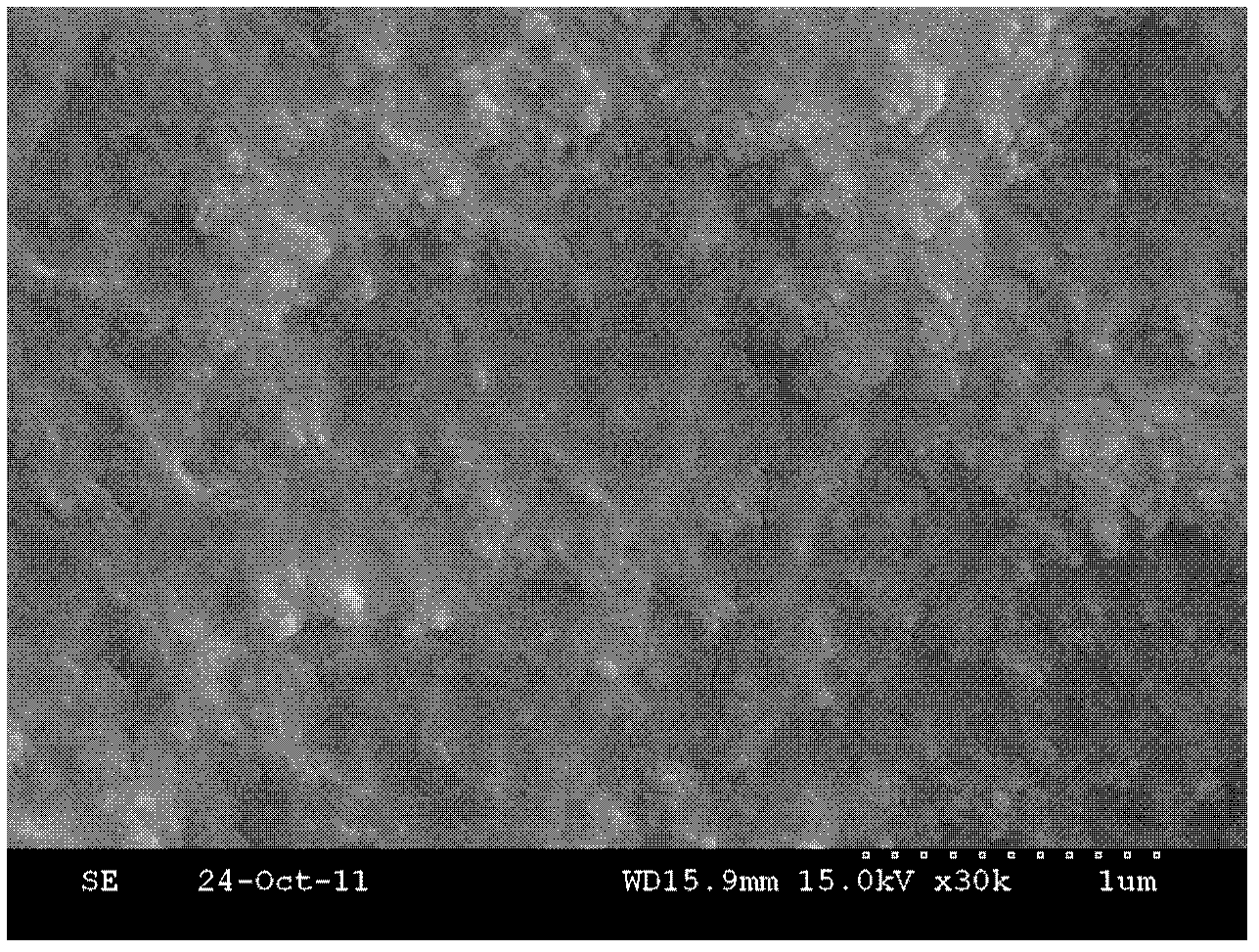

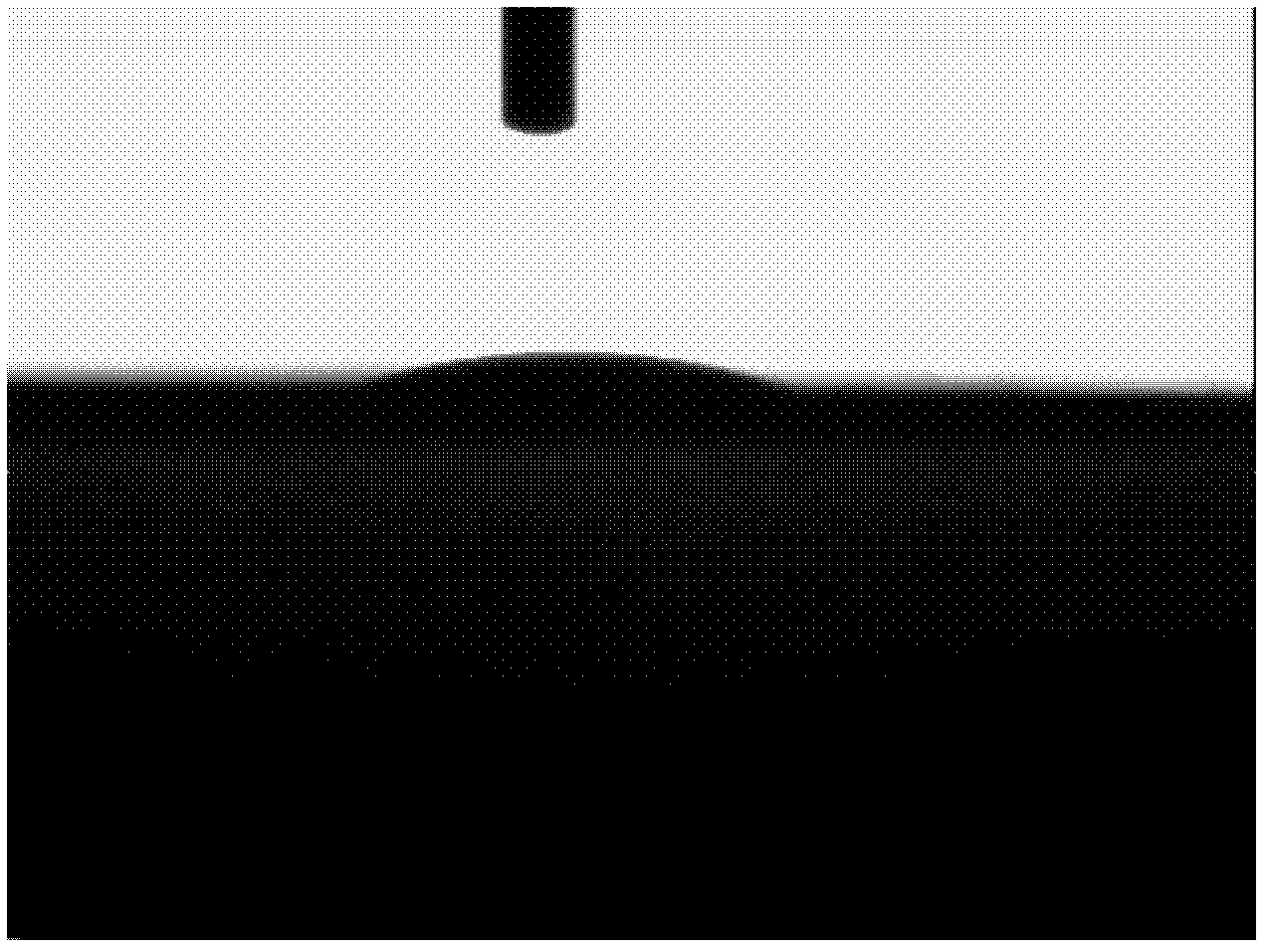

Image

Examples

specific Embodiment 1

[0022] The flat polyacrylonitrile (PAN) ultrafiltration membrane is used as the base membrane, the molecular weight cut off is 20000, and the membrane area is 28cm 2 , the polycationic material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), di(2-hydroxypropionic acid) diammonium titanium hydroxide (TiBisLac , Molecular weight is 294.08), the solvent of polyethylenimine and polyacrylic acid is water.

[0023] Assembly conditions and methods:

[0024] (1) Polyethyleneimine is made into 500ml of a 0.5wt% solution with deionized water, and polyacrylic acid is made into 500ml of a 0.05wt% solution, and left to stand for degassing respectively;

[0025] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65°C, the polypropylene membrane ultrafiltration membrane is im...

specific Embodiment 2

[0033] The base membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 28cm 2 , the polycationic material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), di(2-hydroxypropionic acid) diammonium titanium hydroxide (TiBisLac , Molecular weight is 294.08), the solvent of polyethylenimine and polyacrylic acid is water.

[0034] Assembly conditions and methods:

[0035] (1) Polyethyleneimine is made into 500ml of a 0.5wt% solution with deionized water, and polyacrylic acid is made into 500ml of a 0.05wt% solution, and left to stand for degassing respectively;

[0036] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65°C, the polypropylene membrane ultrafiltration memb...

specific Embodiment 3

[0044] The base membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 28cm 2 , the polycationic material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), di(2-hydroxypropionic acid) diammonium titanium hydroxide (TiBisLac , Molecular weight is 294.08), the solvent of polyethylenimine and polyacrylic acid is water.

[0045] Assembly conditions and methods:

[0046] (1) Polyethyleneimine is made into 500ml of a 0.5wt% solution with deionized water, and polyacrylic acid is made into 500ml of a 0.05wt% solution, and left to stand for degassing respectively;

[0047] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65°C, the polypropylene membrane ultrafiltration memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com