Method for producing seamless titanium and titanium alloy welded pipe

A production method and technology of welded pipes, which are applied in the field of production of seamless titanium and titanium alloy welded pipes, can solve the problems of coarse grains, different metals, and inapplicability to occasions with high environmental requirements, and achieve high yield and high yield. The effect of high production efficiency and significant cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

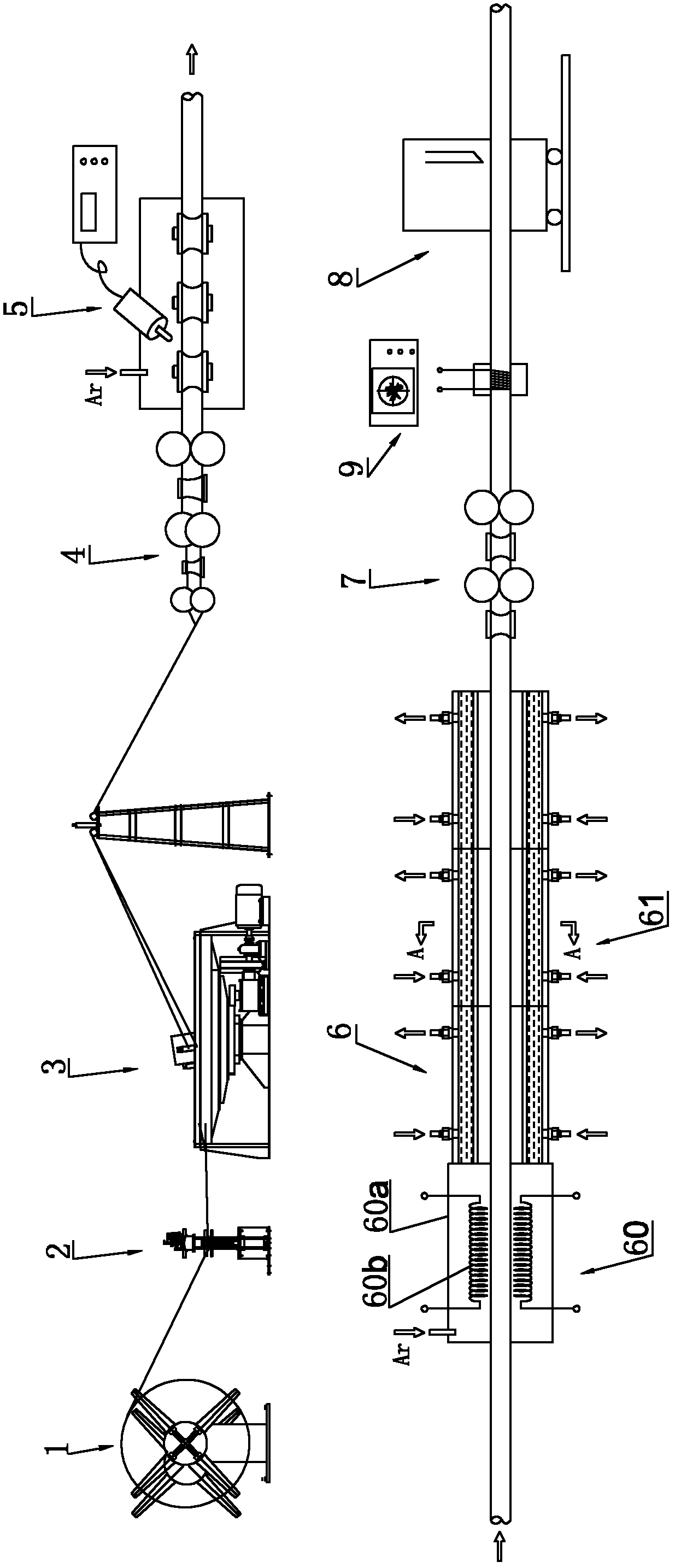

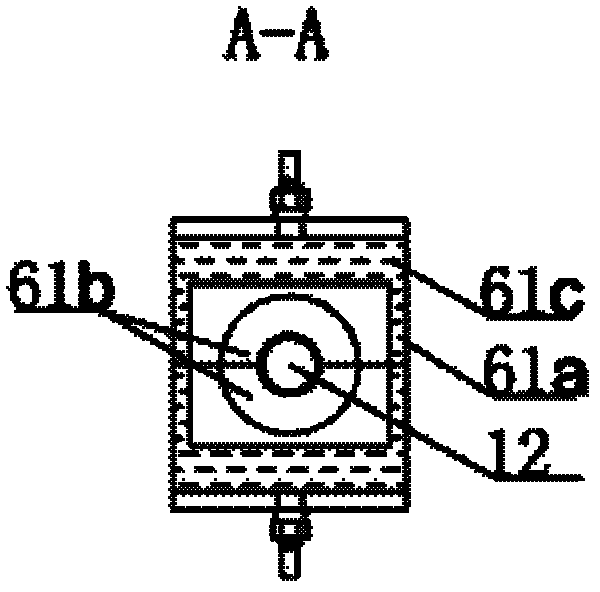

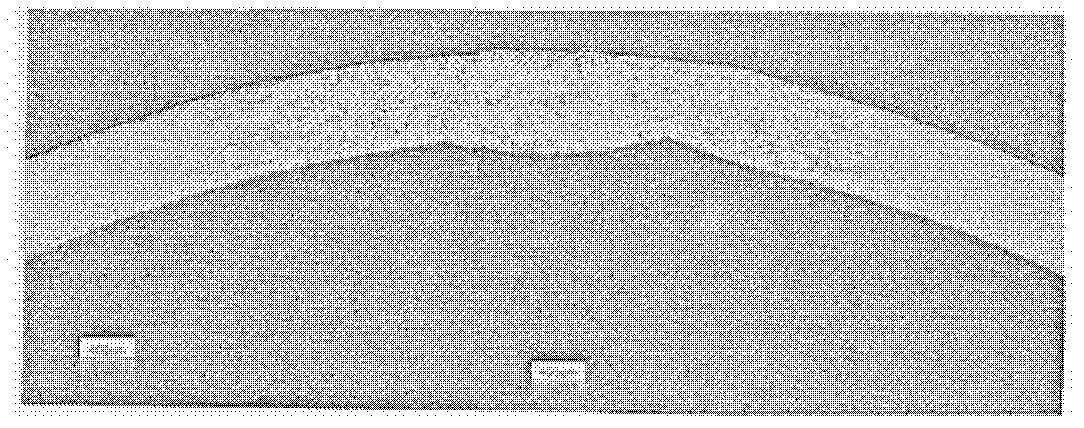

[0029] The main idea of the production method of the titanium and titanium alloy pipes of the present invention is as follows: first, the high-quality welding pipe step is completed on the precision automatic welding production line to obtain welded pipes of titanium or titanium alloys, and then the welded pipes are further subjected to one or more cold rolling -Heat treatment, the weld seam of the welded pipe and the as-cast coarse grains in the heat-affected zone are broken and refined, which is no different from the matrix structure, so as to achieve a seamless effect and meet the needs of the project. In addition, using the method of the present invention, the welded pipe can be cold-rolled to φ25×0.3×8000mm, φ25.3×0.15×6000mm and other titanium pipes with ultra-thin wall and high diameter-thickness ratio (diameter-thickness ratio=outer diameter / wall thickness) .

[0030] The present invention will be described in further detail below in conjunction with the accompan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Maximum non-jamming load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com