Multi-station pinion shaft pressing assembling machine

A small gear and multi-station technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of not considering the reconfigurable requirements of the machine, increasing the cost of the machine, limiting the scope of use, etc., to save manpower and work High efficiency, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

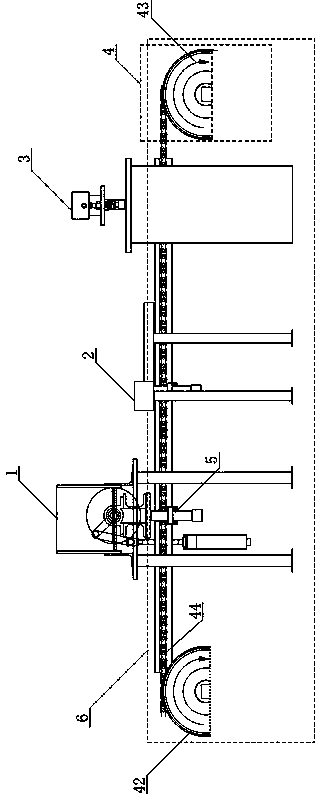

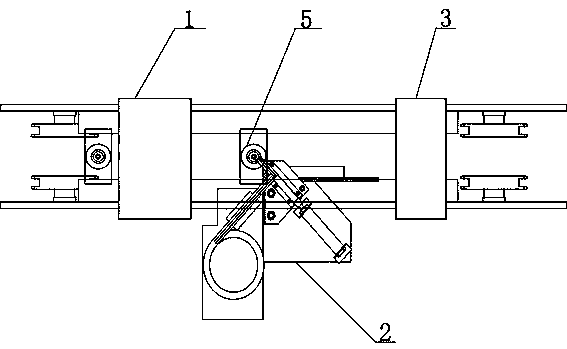

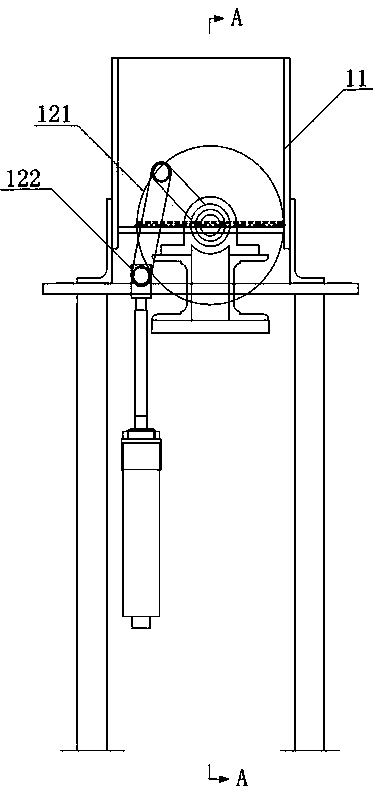

[0042] refer to figure 1 , figure 2 (The drive chain or drive belt is not shown in the figure), image 3 , Figure 6 and Figure 7As shown, the embodiment of the present invention adopts a multi-station assembly method, and decomposes the assembly process into 6 single actions, which are executed simultaneously by 3 stations. It includes a frame 6, a steel shaft feeding device 1, a pinion feeding device 2, a pre-positioning fixture 5, a finale assembly device 3, a transmission mechanism 4 and a control system, wherein the transmission mechanism 4 is installed on the machine On the frame 6, the transmission mechanism 4 includes a motor (not shown in the figure), a main transmission wheel 42, a secondary transmission wheel 43 and a transmission chain or a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com