Multi-manipulator multi-station combination flexible production line for energy-saving doors and windows and processing method of multi-manipulator multi-station combination flexible production line for energy-saving doors and windows

A flexible production line and manipulator technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting large-scale, high-efficiency, high-quality plastic doors and windows, difficult to achieve modular combination, and unstable processing quality. Achieve the effect of improving processing quality and work efficiency, shortening processing cycle, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

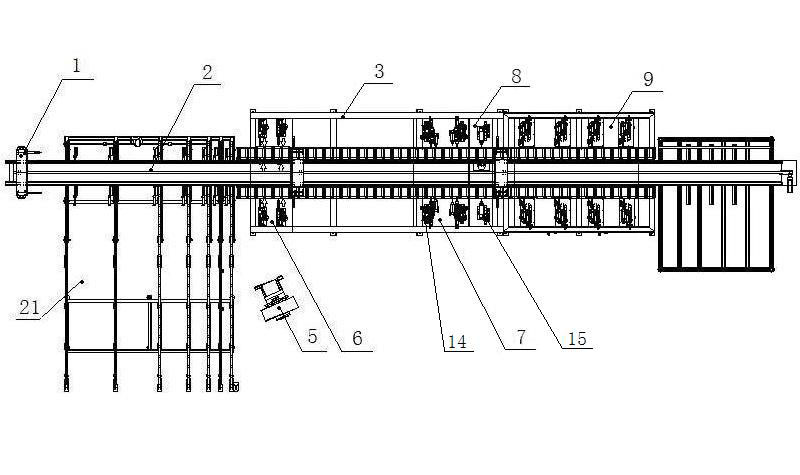

[0032] Such as figure 1 Shown is the structural representation of the present invention.

[0033] The invention includes an energy-saving door and window multi-manipulator multi-station combined flexible production line, including a nailing processing unit 6, a water tank processing unit 7, a lock hole processing unit 8, an installation hole processing unit 9, a host computer 5, and a conveying channel 2 for transmitting profiles And the frame 3 for installing the above-mentioned processing unit and conveying channel.

[0034] The nailing processing unit 6, the water tank processing unit 7, the keyhole processing unit 8 and the mounting hole processing unit 9 are successively arranged on both sides of the conveying channel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com