Microstructure for detecting mechanical properties of one-dimensional nanometer materials

A nano-material and micro-structure technology, applied in the field of micro-mechanical technology and nano-material science, can solve the problems that the load of the sample and the deformation of the sample cannot be measured separately at the same time, the calculation error is large, and the implementation cost is high, so as to achieve intuitive measurement and reduce the impact , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

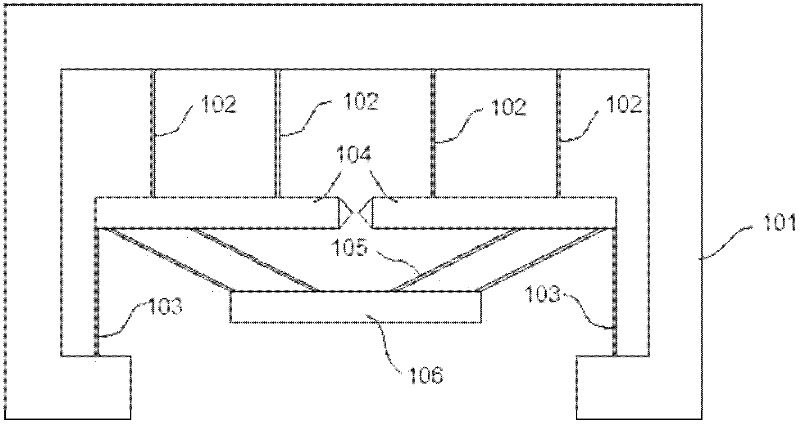

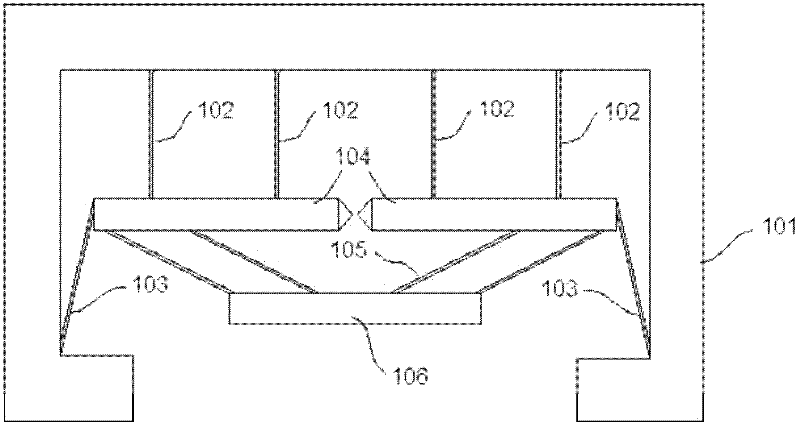

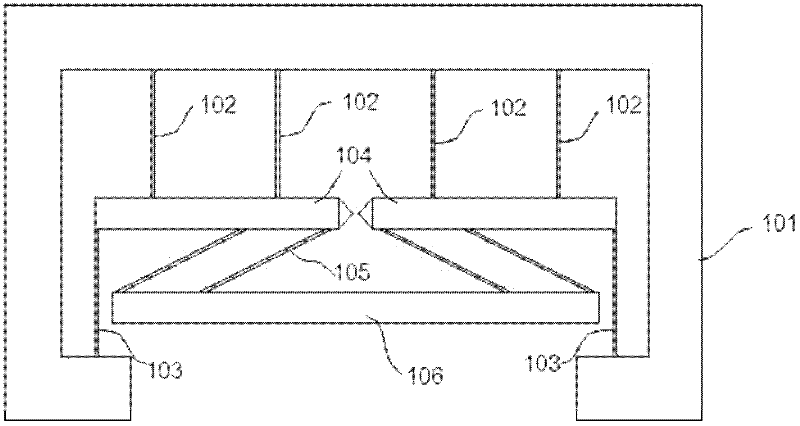

[0039] The preparation process of the present invention will be further described with reference to FIG. 3 below.

[0040] 3(a), 01 is the device layer, the material is polysilicon, and the thickness is about 10μm; 02 is the sacrificial layer, and the material is silicon oxide; 03 is the silicon substrate; 04 is the protective layer; 05 is the primary photoresist; 06 is Secondary photoresist.

[0041] 3(b), a layer of photoresist 05 is coated on the surface of the device layer.

[0042] 3(c), the photoresist is etched to form a micromechanical structure pattern.

[0043] 3(d), the device layer is etched to form a micromechanical structure.

[0044] Referring to Figure 3(e), the photoresist is removed.

[0045] 3(f), a photoresist 06 is coated on the surface of the etched device layer and the protective layer.

[0046] Referring to FIG. 3(g), the photoresist of the etching protection layer is etched, and the size is the size of the observation window.

[0047] Referring to FIG. 3(h), the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com