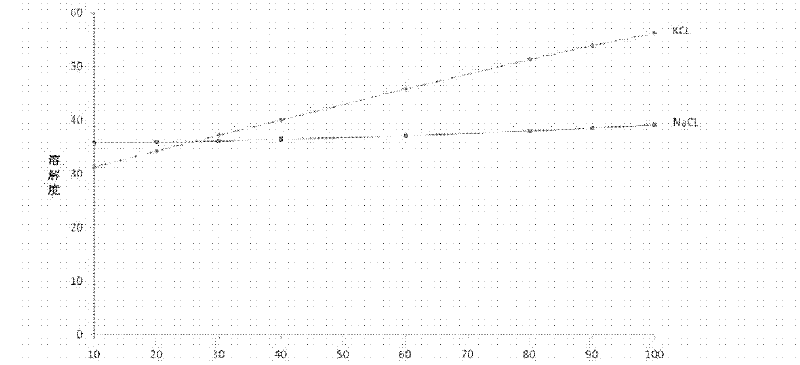

Method for respectively crystallizing and separating sodium chloride and potassium chloride in industrial wastewater with sodium chloride and potassium chloride

A technology for separation of industrial wastewater and crystallization, applied in the direction of alkali metal chloride, etc., can solve the problems of low crystal yield, poor economic benefit, and low purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

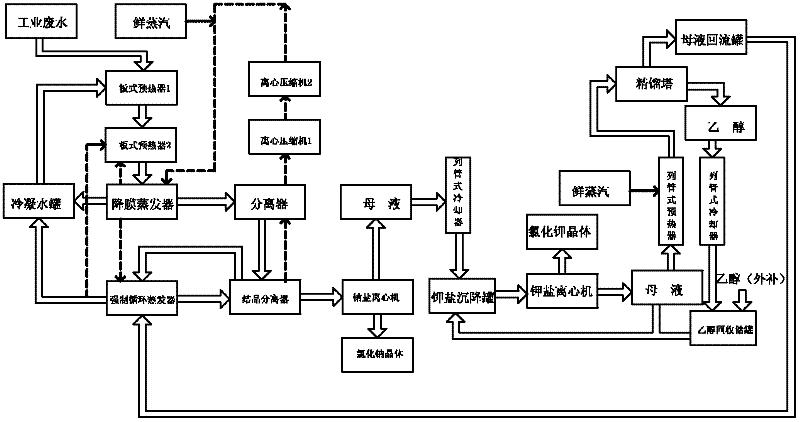

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (the situation that does not add ethanol)

[0035] Adopt pretreated industrial waste water (mass concentration is 3% sodium chloride and potassium chloride mixed solution, wherein the mass ratio of sodium chloride and potassium chloride is 7: 3) 3L, it is evaporated at 101 ℃ Concentrate, and when the evaporated water is 2.914L, potassium chloride reaches saturation. At this time, 41g of sodium chloride crystals are separated out, and the concentrated liquid obtained is 86ml, which contains 27g of potassium chloride and 22g of sodium chloride.

[0036] The obtained concentrated liquid, i.e. the saturated solution of potassium chloride, was cooled to 30° C. and left to stand for a period of time. Crystals were separated and separated. The crystals were 3.187 g, including 0.347 g of sodium chloride and 2.84 g of potassium chloride.

Embodiment 2

[0037] Embodiment 2 (agent water ratio is the situation of 30%)

[0038] Adopt pretreated industrial waste water (mass concentration is 3% sodium chloride and potassium chloride mixed solution, wherein the mass ratio of sodium chloride and potassium chloride is 7: 3) 3L, it is evaporated at 101 ℃ Concentrate, and when the evaporated water is 2.914L, potassium chloride reaches saturation. At this time, 41g of sodium chloride crystals are separated out, and the concentrated liquid obtained is 86ml, which contains 27g of potassium chloride and 22g of sodium chloride.

[0039] The obtained concentrated liquid, i.e. the saturated solution of Potassium Chloride, is cooled to 30°C, and 14ml of dehydrated alcohol is added, (agent-to-water ratio W=30%, the ratio of dehydrated alcohol to water is the quality of dehydrated alcohol and the quality of water in the concentrated liquid ratio), preferably, the mixed solution can be stirred evenly with a glass rod to help mix. At 30°C, after ...

Embodiment 3

[0040] Embodiment 3 (agent water ratio is the situation of 50%)

[0041] Adopt pretreated industrial waste water (mass concentration is 3% sodium chloride and potassium chloride mixed solution, wherein the mass ratio of sodium chloride and potassium chloride is 7: 3) 3L, it is evaporated at 101 ℃ Concentrate, and when the evaporated water is 2.914L, potassium chloride reaches saturation. At this time, 41g of sodium chloride crystals are separated out, and the concentrated liquid obtained is 86ml, which contains 27g of potassium chloride and 22g of sodium chloride.

[0042] The obtained concentrated liquid, i.e. the saturated solution of potassium chloride, is cooled down to 30°C, and 23ml of dehydrated alcohol is added, (agent-water ratio W=50%), preferably, the mixed solution can be stirred evenly with a glass rod to help The role of mixing. At 30°C, after standing for a period of time, crystals were separated, and the crystals were 19.91g, including 1.80g of sodium chloride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com