Supercentrifuge for separation of liquaemin waste water and saline water

A high-speed centrifuge, heparin sodium technology, applied in the direction of centrifugal separation water/sewage treatment, osmotic/dialysis water/sewage treatment, etc., can solve the problem of effective resource waste, achieve the effect of recycling and improving the effective utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

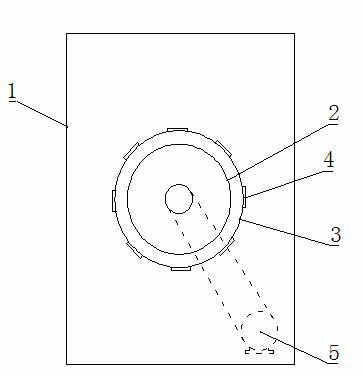

[0007] Such as figure 1 As shown, a casing 1 is included, and the casing 1 has a built-in centrifugal cylinder 2 driven by a motor, and several screen holes are uniformly distributed on the wall of the centrifugal cylinder 2 .

[0008] It also includes a separation cylinder 3 coaxially arranged outside the centrifuge cylinder 2, a number of separation windows 4 are opened on the side wall of the separation cylinder 3, and microfiltration membranes are installed on the separation windows 4.

[0009] When in use, open the window at the end of the centrifuge cylinder, inject the heparin sodium wastewater into the centrifuge cylinder 2, and use the motor 5 to drive the centrifuge cylinder 2 to rotate, so that the heparin sodium wastewater passes through the sieve hole and is thrown onto the wall of the separation cylinder 3 under centrifugal action. The solid impurities contained therein are left in the centrifuge cylinder 2, and the water passes through the microfiltration membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com