Non-paddle bypass type underwater pushing, transporting and stirring method and device

The technology of a stirring device and a stirring method, which is applied in the field of water treatment, can solve the problems such as the flushing of microorganisms on the surface of the filler, the crushing of the filler, the inability to play the role of propulsion and transportation, and the improvement of biochemical efficiency, efficiency and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

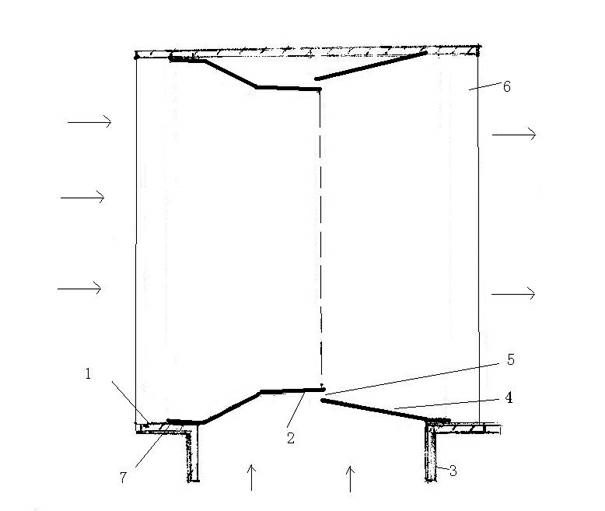

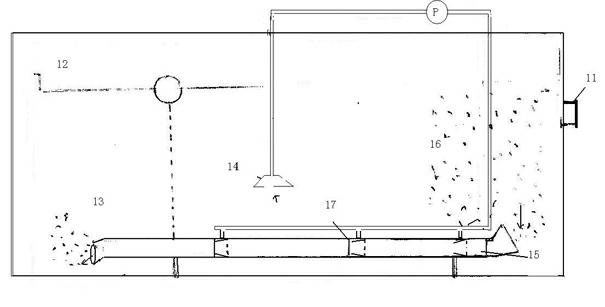

[0015] As shown in the figure, the shell 1, the cone mouth 2, the pressure water inlet pipe 3, the retaining ring 4, the spout or uniform slit 5, and the filler delivery outlets 6 and 7 are regulating devices. figure 2 Middle P is a pressure pump, a pool water outlet 11, a horizontal line suspension 12, an outlet 13 for output packing, a pressure pump water inlet 14, a packing inlet 15, a packing layer 16, and a propeller 17. . The present invention is based on the structure and principle of the annular jet, and uses or other pressure water flow (the pump is commonly used, the suction port of the pump) to inject water from the slit of the annular jet, thereby driving the surrounding water flow to move forward together. When implementing, It can be used alone, or two or more of them can be connected in series with pipelines to achieve the purpose of long-distance transportation of fillers.

[0016] The pipe or cylinder shell of the present invention can be cylindrical or rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com