Continuous sequencing-batch aerobic subsequent treatment section influent water flow control device and flow buffer method

A technology of flow control device and treatment section, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. To solve problems such as treatment effect, to achieve the effect of reducing drug consumption, reducing frequent adjustment, and convenient follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

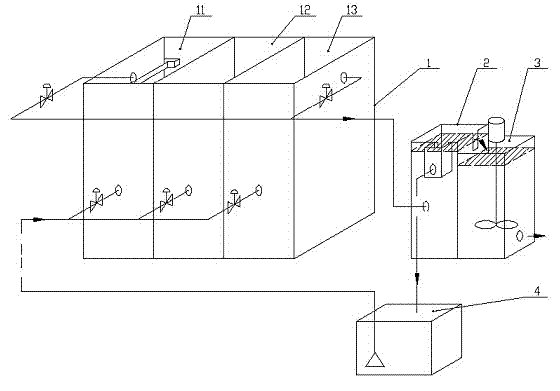

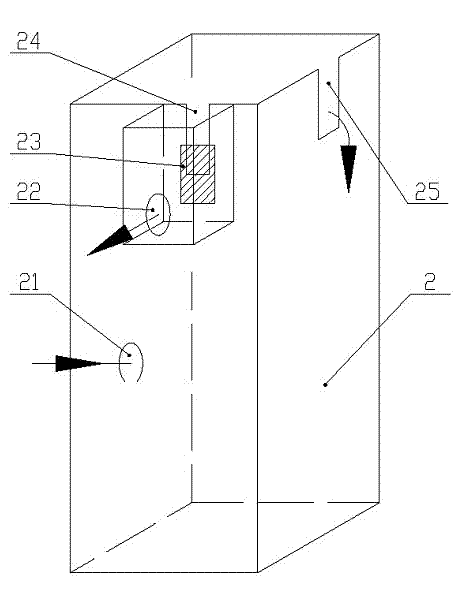

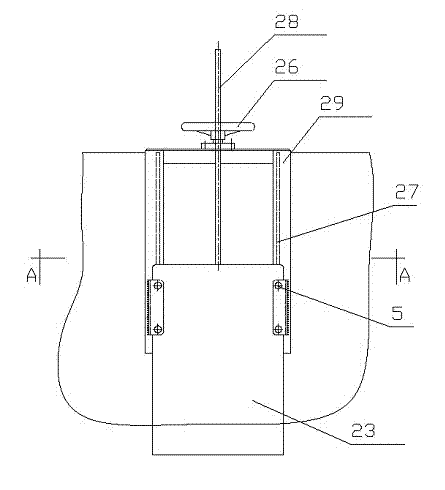

[0020] like figure 1 , 2 , 3, the UNITANK aerobic pool 1 is subsequently connected to the buffer pool 2 and the coagulation pool 3, the effluent from the functional weir 24 of the buffer pool 2 flows back to the sump 4, and the waste water from the sump 4 enters the system through the lift pump, and the UNITANK pool Including side pool 11, middle pool 12 and side pool 13, buffer pool 2 includes water inlet 21, functional weir 24 and water outlet 25, functional weir 24 is provided with a sealing gate 23 to control the elevation of the weir mouth, and the outlet water of the weir mouth is collected by the collection tank through The return port 22 is discharged, and the outlet water from the buffer tank 2 enters the coagulation tank 3 . The sealing gate 23 is inserted into the gate seat 29, the screw rod 28 is connected to the gate plate 23, and the rotatable handwheel 26 is fixed on the gate seat 29. The handwheel 26 cooperates with the threaded mandrel 28, so that the gate ca...

Embodiment 2

[0023] like figure 1 , 2 , 3, UNITANK pool 1 is subsequently connected to buffer pool 2 and coagulation pool 3 in turn, the effluent from the functional weir 24 of buffer pool 2 flows back to sump 4, and the waste water from sump 4 enters the system through a lift pump, and the UNITANK pool includes side The pool 11, the middle pool 12 and the side pool 13. The buffer pool 2 includes a water inlet 21, a functional weir 24 and a water outlet 25. The functional weir 24 is provided with a sealing gate 23 to control the elevation of the weir mouth. The outlet water of the weir mouth is collected by the collection tank through the return port 22 is discharged, and the effluent from the buffer tank 2 enters the coagulation tank 3.

[0024] In a design water volume of 200m 3 In the waste water treatment system per hour, the buffer tank 2 is designed to be 1500mm×1500mm×5000mm, the diameter of the water inlet 21 is DN300mm, the width of the water outlet 25 is 100mm, and the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com