Preparation method for bentonite anti-seepage material

A technology of anti-seepage material and bentonite, which is applied in the field of preparation of anti-seepage materials, can solve the problems of unreported and few studies on the application of domestic waste landfills, and achieve sufficient raw material resources, good anti-seepage performance, and preparation The effect of simple process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

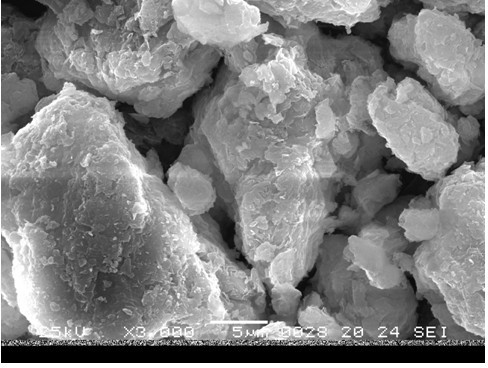

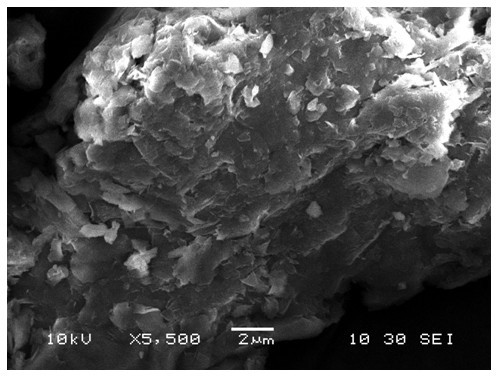

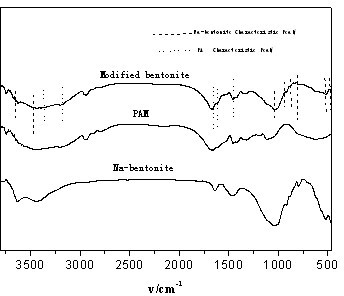

Image

Examples

Embodiment Construction

[0018] Ratio of n(PAM):n(F):n(AM) in modified polyacrylamide and modified polyacrylamide and bentonite.

[0019] 1) Influence of molar ratio: The degree of crosslinking of modified polyacrylamide room temperature cross-linked product changes with its molar ratio (n(PAM):n(F):n(AM)): when the molar ratio increases , the cross-linking degree of the room temperature cross-linking product decreases, this is because the cross-linking reaction occurs between the active groups of the room temperature cross-linking polyacrylamide side chains, and the change of the cross-linking degree is related to the active groups on the side chains. It can be inferred that the number of active groups in the side chain of modified polyacrylamide will directly affect the change of its pores and the performance of anti-seepage materials. In practical applications, the degree of crosslinking can be adjusted at any time according to actual requirements. It is easy to control the overall stability of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com