Anti-crack concrete for wharf surface layer and preparation method for anti-crack concrete for wharf surface layer

A technology of concrete and surface layer, which is applied in the field of anti-crack concrete for wharf surface layer and its preparation. It can solve the problems of too late cutting time, concrete damage, and failure to effectively inhibit crack expansion, etc., and achieve high crack resistance and good workability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

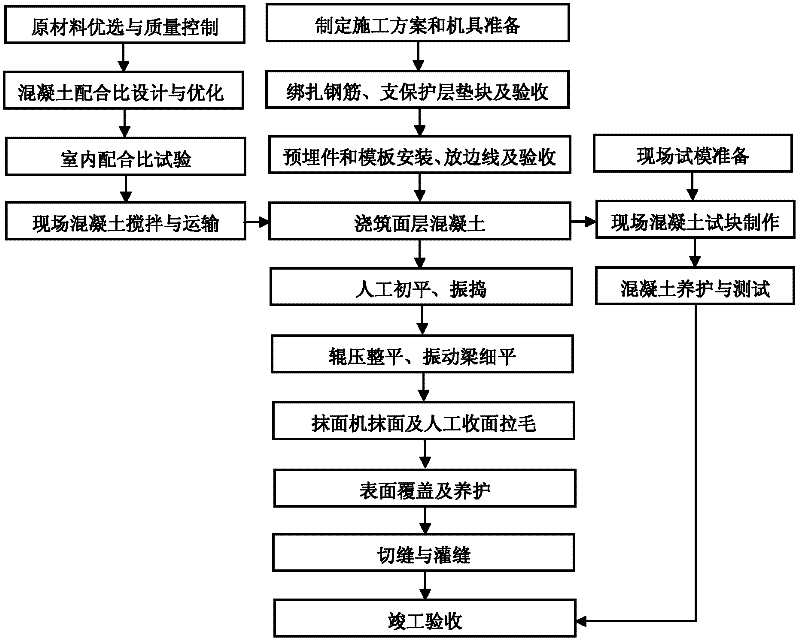

[0109] 1. Preparation of anti-crack concrete for wharf surface:

[0110] The raw material components of the crack-resistant concrete for the wharf surface and their corresponding proportions are shown in Table 1-1. The raw materials used are as follows: cement is P.O42.5 cement produced by Shanghai Wanan Enterprise Corporation; Class II fly ash produced by Shanghai Xinbao Fly Ash Factory is used; Shanghai Tongji Ark Special Building Materials Co., Ltd. Changjian The polypropylene fiber produced by the brand has a diameter of 18μm, a length of 12mm, and an elastic modulus of 3500MPa; the coarse aggregate is 5-31.5 continuous graded crushed stones (based on the total weight of the continuously graded crushed stones, which contain The amount of mud is less than 0.6%, and the content of needle-shaped gravel is less than 7%); the fine aggregate is river sand with a fineness modulus greater than 2.6 and less than 3.0 (based on the total weight of the river sand, its mud content is n...

Embodiment 2

[0135] According to the preparation method of Example 1, the anti-crack concrete for the wharf surface of this example was prepared, and its raw materials and proportions are shown in Table 2-1.

[0136] Table 2-1 Raw material components and corresponding proportions of crack-resistant concrete for wharf surface

[0137]

[0138] After testing, the strength grade of the crack-resistant concrete on the wharf surface obtained in this embodiment reaches C35, the slump of the concrete is 75 mm, and the slump loss in 1 hour is less than 10 mm.

[0139] The wharf surface layer crack-resistant concrete that present embodiment obtains has good workability, and concrete slump is 75mm; Concrete compressive strength test result is: 28 days compressive strength is 43.1MPa; Record concrete plastic shrinkage result by plate test: No cracks appear; measured 180-day drying shrinkage is 341×10 -6 ; The measured 28-day splitting tensile strength is 3.46MPa, and the 90-day splitting tensile ...

Embodiment 3

[0141] According to the preparation method of Example 1, the anti-crack concrete for the wharf surface of this example was prepared, and its raw materials and proportions are shown in Table 3-1.

[0142] Table 3-1 Raw material components and corresponding proportions of crack-resistant concrete for wharf surface

[0143]

[0144] After testing, the strength grade of the crack-resistant concrete on the wharf surface obtained in this embodiment reaches C35, the slump of the concrete is 75 mm, and the slump loss in 1 hour is less than 10 mm.

[0145] The workability of the wharf surface crack-resistant concrete obtained by the present embodiment is good, and the concrete slump is 75mm; the concrete compressive strength test result is: the 28-day compressive strength is 46.5MPa; the concrete plastic shrinkage result recorded by the plate test is: No cracks appear; measured 180-day drying shrinkage is 385×10 -6 ;The measured 28-day splitting tensile strength is 3.61MPa, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com