Coating capable of reducing heating oxidation burning loss of steel billets

A billet heating and coating technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of low anti-oxidation efficiency, corrosion of steel, narrow application range of stainless steel, etc., achieve long heating time, reduce burning loss, and significant use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

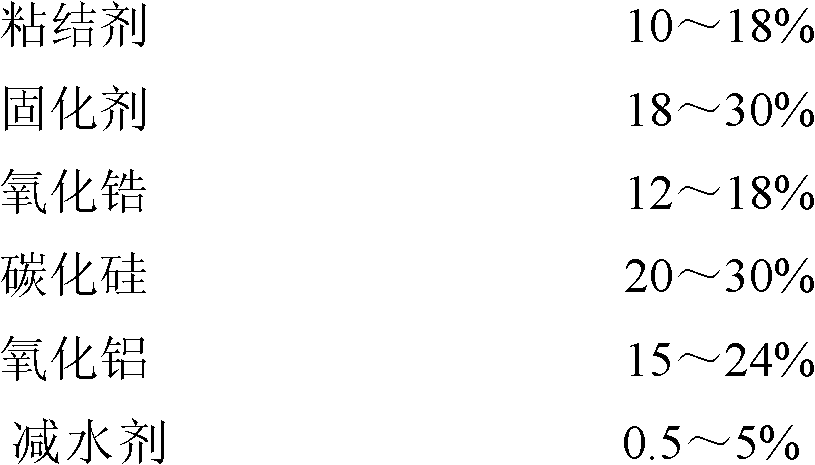

Method used

Image

Examples

Embodiment 1

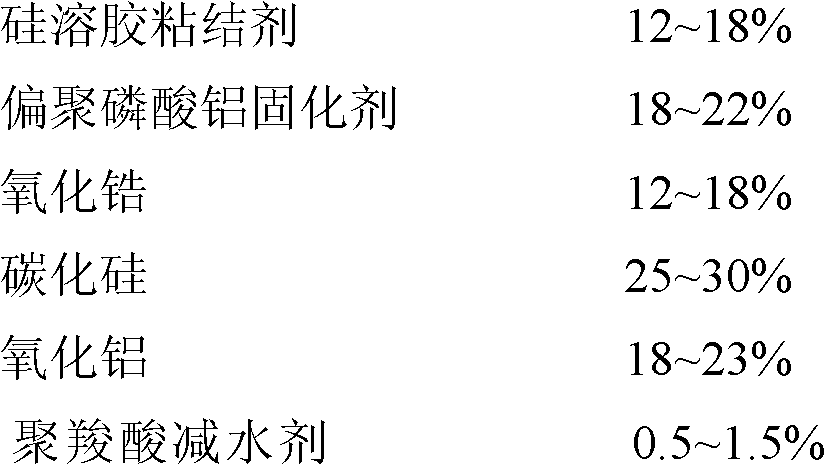

[0032] The coating that reduces the heating and oxidation burning of steel billets, the chemical composition and weight percentage content are: 15% of silica sol binder, 20% of aluminum metaphosphate curing agent, 15% of zirconia, 28% of silicon carbide, 21% of aluminum oxide, poly Carboxylic acid superplasticizer 1%.

Embodiment 2

[0034] The coating that reduces the heating and oxidation burning of steel billets, the chemical composition and weight percentage are: 10% of silica sol binder, 24% of aluminum metaphosphate curing agent, 12% of zirconia, 30% of silicon carbide, 22% of aluminum oxide, poly Carboxylic acid superplasticizer 2%.

Embodiment 3

[0036] The coating that reduces the heating and oxidation burning loss of steel billets, the chemical composition and weight percentage are: 12% silica sol binder, 22% aluminum metaphosphate curing agent, 16% zirconia, 29% silicon carbide, 18% aluminum oxide, poly Carboxylic acid superplasticizer 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com