Preparation method and application of molecularly imprinted polymer for directionally protecting functional groups

A technology of molecular imprinting and polymers, applied in the direction of steroids, chemical instruments and methods, ion exchange, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030]A method for preparing molecularly imprinted polymers with directional protection functional groups, the steps are as follows:

[0031] 1) Take 25g of macroporous aminomethyl resin microspheres of 200-400 mesh, in 200mL Na 2 HPO 4 -NaH 2 PO 4 Swell in buffer for 1 hour;

[0032] 2) Mix 5.114mL of methacrylic acid, 13.80g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 16.57g of N-hydroxysulfosuccinimide in a volume ratio of 3: 17. 200mL Na with a concentration of 20mM and a pH of 6.1 2 HPO 4 -NaH 2 PO 4 Stirring is carried out at 4°C for 1 hour in the buffer;

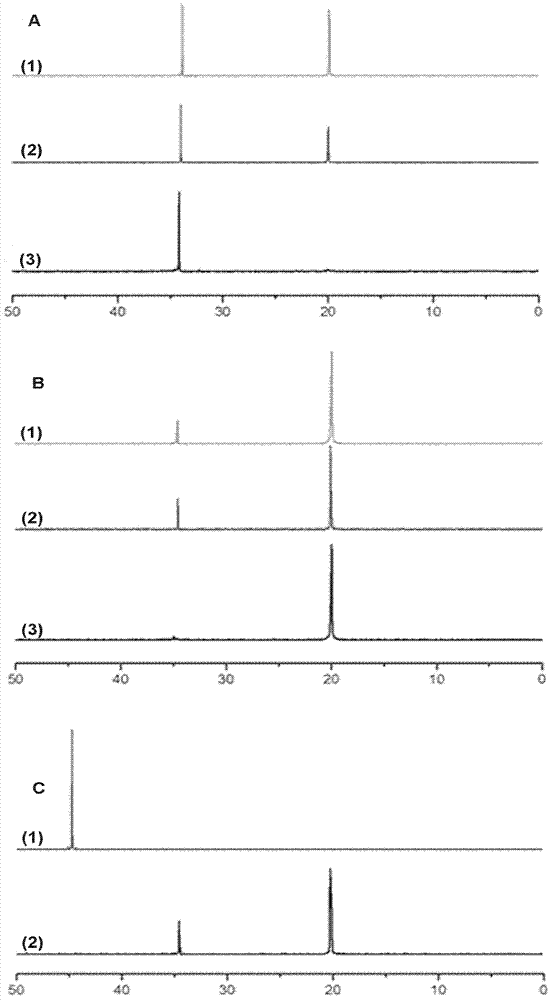

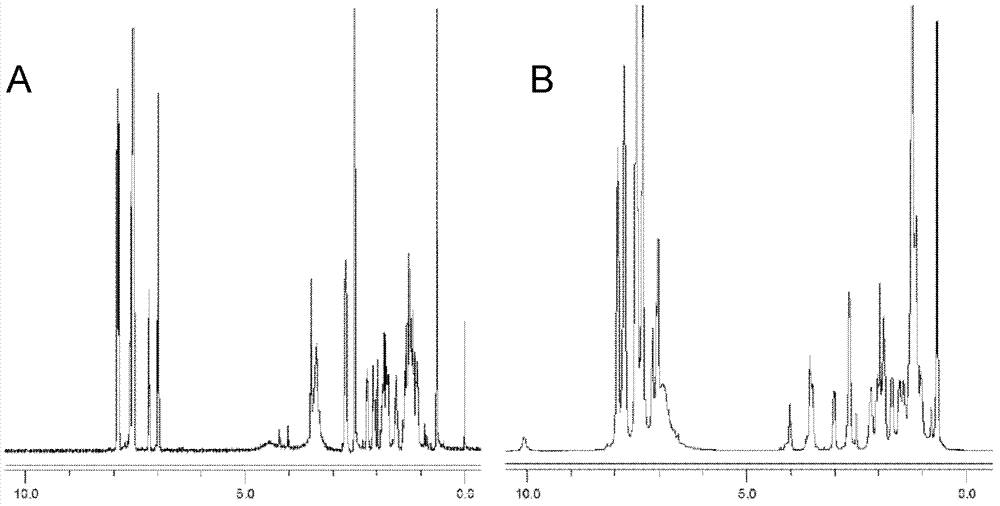

[0033] 3) Add swollen macroporous aminomethyl resin microspheres to the above reaction system, and react at room temperature for 16 hours, so that the amino groups on the microspheres are grafted with methacryloyl groups, and then suction filtered and vacuum-dried for 24 hours to obtain Double bond modified macroporous aminomethyl resin microsphere carrier, the product is tested by infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com