Preparation method of special high-elasticity high-impregnation room temperature curing two-component interpentration polyurethane patching material for ballastless track boss resin patching

A ballastless track, room temperature curing technology, used in tracks, roads, ballast layers, etc., can solve the problems of low polyether polyol content, poor compatibility, poor permeability, etc., and achieve high compressive strength and dimensional stability. Good, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

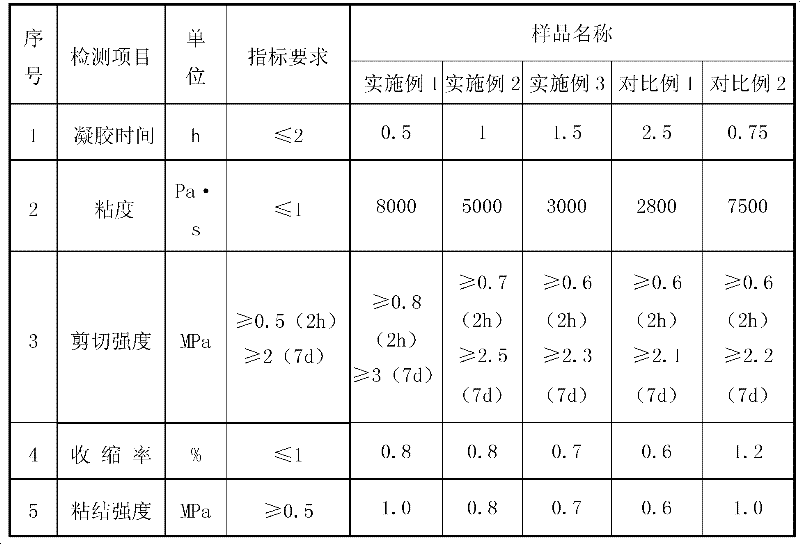

Examples

Embodiment 1

[0020] Example 1: A method for preparing a high-elasticity and high-wetting room-temperature-curing two-component interpenetrating polyurethane repair material for ballastless track boss resin repair, including:

[0021] (1) Preparation of modified interpenetrating polyether elastomer: 33kg of polyether polyol 1 and 6kg of polyether polyol 2 were heated to 80°C for 2 hours, and 13kg of polyether polyol 3 and 13kg of hard foam were added to the above system For polyether polyol 4, heat up to 90°C and react for 2 hours, then continue to heat up to 120°C, take out small molecules by passing inert gas, react for 2 hours, and discharge after cooling;

[0022] (2) Synthesis of linear block MDI prepolymer: Add 10kg of MDI into the dry reaction kettle and feed inert gas, then add 70kg of polyether glycol PPG and 3kg of dibutyltin dilaurate dropwise, and react at 90°C for 3h, Then add 150kg of acetone for dilution, cool down to 80°C, add 10kg of dimethylolpropionic acid, and end the re...

Embodiment 2

[0024] Example 2: A method for preparing a high-elasticity and high-wetting room-temperature-curing two-component interpenetrating polyurethane repair material for ballastless track boss resin repair, including:

[0025] (1) Preparation of modified interpenetrating polyether elastomer: 30kg of polyether polyol 1 and 6kg of polyether polyol 2 were heated to 80°C for 2 hours, and 15kg of polyether polyol 3 and 15kg of hard foam were added to the above system For polyether polyol 4, heat up to 90°C and react for 2 hours, then continue to heat up to 120°C, take out small molecules by passing inert gas, react for 2 hours, and discharge after cooling;

[0026] (2) Synthesis of linear block MDI prepolymer: Add 10kg of MDI into the dry reaction kettle and feed inert gas, then add 70kg of polyether glycol PPG and 3kg of dibutyltin dilaurate dropwise, and react at 90°C for 3h, Then add 175kg of acetone for dilution, cool down to 80°C, add 10kg of dimethylolpropionic acid, and end the re...

Embodiment 3

[0028] Embodiment 3: The preparation method of special high-elasticity and high-wet room temperature curing two-component interpenetrating polyurethane repair material for ballastless track boss resin repair, including

[0029] (1) Preparation of modified interpenetrating polyether elastomer: 30kg of polyether polyol 1 and 6kg of polyether polyol 2 were heated to 80°C for 2 hours, and 15kg of polyether polyol 3 and 15kg of hard foam were added to the above system For polyether polyol 4, heat up to 90°C and react for 2 hours, then continue to heat up to 120°C, take out small molecules by passing inert gas, react for 2 hours, and discharge after cooling;

[0030] (2) Synthesis of linear block MDI prepolymer: Add 10kg of MDI into the dry reaction kettle and feed inert gas, then add 70kg of polyether glycol PPG and 3kg of dibutyltin dilaurate dropwise, and react at 90°C for 3h. Then add 200kg of acetone for dilution, cool down to 80°C, add 10kg of dimethylolpropionic acid, and end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com