Efficient conduction material

A conductive material and high-efficiency technology, applied in the field of high-efficiency conductive materials, can solve the problems of increasing process complexity and increasing manufacturing costs, and achieve the effect of increasing production costs and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

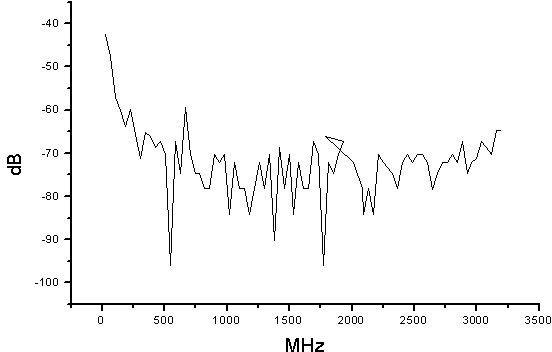

[0033] Use 1601 epoxy resin as the matrix material, and polyamide resin 650 as the curing agent. Mix epoxy resin and curing agent at a ratio of 1:1 (weight percentage), then pour it into a mold coated with simethicone oil, and lay a layer of density 150 g / m on the mixture 2 The aluminum fiber non-woven felt layer, continue to pour the mixture of the remaining epoxy resin and curing agent into the mold, then close the mold, keep it under a certain pressure for 4 hours to cure the material, and finally demould. The prepared material has good electromagnetic shielding performance, at 300MHz-3198 MHz, the electromagnetic shielding performance is 70-90dB, and the electromagnetic shielding effect reaches 99.99%. Test results such as figure 1 .

Embodiment 2

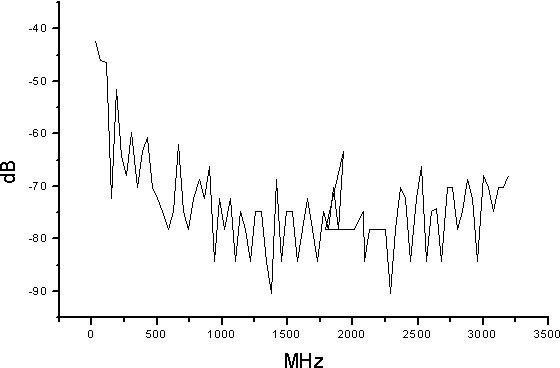

[0035] The selected area density is 100 g / m 2 The aluminum fiber non-woven surface thin felt layer is used as the conductive layer. In the process of preparing glass cloth reinforced epoxy resin by conventional hand lay-up method, when pasting the inner layer of the product (not too close to the outer layer, so as not to prevent the aluminum fiber non-woven felt exposed), replace a layer of glass cloth with an aluminum fiber non-woven surface felt layer. After the pasting is completed, solidify and demould. The prepared material has good electromagnetic shielding performance, 400MHz-3198 MHz, the electromagnetic shielding performance is 70-90dB, and the electromagnetic shielding effect reaches 99.99%. Test results such as figure 2 .

Embodiment 3

[0037] In the process of preparing plastics by conventional resin die-casting (ie, injection molding), a glass fiber reinforced layer and an aluminum fiber non-woven felt layer of a specific shape are laid in the mold in advance, and the hot melted plastic is injected into the mold cavity by high pressure. After cooling and solidification, the molded product is obtained by demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com