Separation method for solid particles in catalytic slurry oil

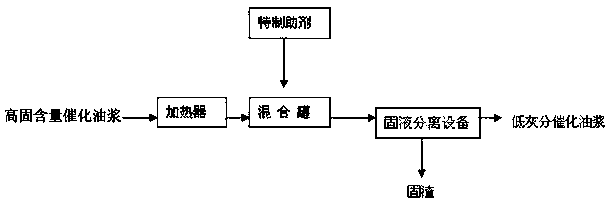

A technology for catalyzing oil slurry and solid particles, which is applied in the field of petrochemical industry, can solve the problems of non-continuous production and poor separation effect, and achieve the effect of complete separation, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Heat treatment: use a heater to heat the high solid content catalytic oil slurry with catalyst powder to 100°C

[0048] (2) Additive mixing: In the mixing tank, add a special additive with a slurry content of 5%, and stir moderately to make the slurry form a completely random mixed flow, with a flow rate of 37 m / s, and stir for 20 minutes to make the catalyst powder interact with each other. impact coalescence;

[0049] (3) Solid-liquid separation: use a plate-and-frame filter press to separate, so as to obtain low-ash catalytic oil slurry and form solid slag from catalyst dust to precipitate.

Embodiment 2

[0051] (1) Heat treatment: use a heater to heat the high solid content catalytic oil slurry with catalyst powder to 150°C

[0052] (2) Additive mixing: In the mixing tank, add a special additive with a slurry content of 1%, and stir moderately to make the slurry form a completely random mixed flow, with a flow rate of 25 m / s, and stir for 40 minutes to make the catalyst powder interact with each other. impact coalescence;

[0053] (3) Solid-liquid separation: use a plate-and-frame filter press to separate, so as to obtain low-ash catalytic oil slurry and form solid slag from catalyst dust to precipitate.

Embodiment 3

[0055] (1) Heating treatment: use a heater to heat the high solid content catalytic oil slurry with catalyst powder to 200°C

[0056](2) Additive mixing: In the mixing tank, add a special additive with a slurry content of 3%, and stir moderately to make the slurry form a completely random mixed flow, with a flow rate of 30 m / s, and stir for 30 minutes to make the catalyst powder interact with each other. impact coalescence;

[0057] (3) Solid-liquid separation: use a plate-and-frame filter press to separate, so as to obtain low-ash catalytic oil slurry and form solid slag from catalyst dust to precipitate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com