Clothes washing rinsing synergist containing methyl sulfate-based quaternary ammonium salt

A technology based on quaternary ammonium salts and methyl sulfate, applied in the direction of organic washing compositions, etc., can solve the problems of yellowing and hardening of clothes, excessive foam, and difficulty in rinsing quickly, achieve white clothes, eliminate chemical residues, and facilitate laundry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

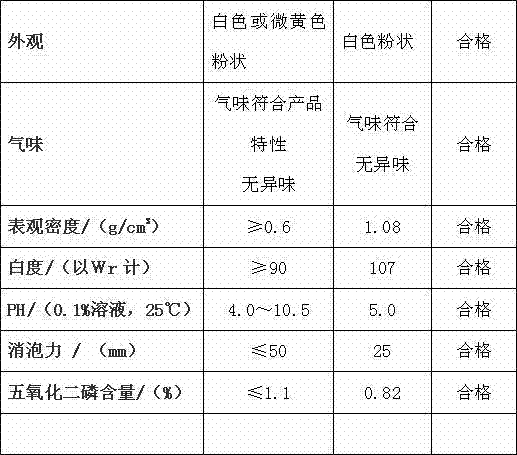

Examples

Embodiment 1

[0028] Take 0.5 parts of polyethoxylated fatty alcohol, 2 parts of polyethoxylated isomeric fatty alcohol, 1.5 parts of citric acid, 5 parts of sodium citrate, 0.1 part of polydimethylsiloxane, distearyl ester- 0.2 parts of hydroxyethyl-methyl-ammonium methylsulfate, 0.1 part of methyl-oleamidoethyl-oleic acid-imidazoline ammonium methylsulfate, 0.1 part of essence, 70 parts of sodium sulfate, 10 parts of sodium chloride, According to the process of producing powdered washing powder, the laundry rinse synergist containing methyl sulfate group quaternary ammonium salt is produced.

Embodiment 2

[0030] Take 2.5 parts of polyethoxylated fatty alcohol, 1 part of polyethoxylated isomeric fatty alcohol, 2.5 parts of citric acid, 7 parts of sodium citrate, 0.3 part of polydimethylsiloxane, distearyl ester- 0.4 parts of hydroxyethyl-methyl-ammonium methyl sulfate, 0.2 parts of methyl-oleamidoethyl-oleyl-imidazoline ammonium methyl sulfate, 0.2 parts of essence, 65 parts of sodium sulfate, 15 parts of potassium chloride, According to the process of producing powdered washing powder, the laundry rinse synergist containing methyl sulfate group quaternary ammonium salt is produced.

Embodiment 3

[0032] Take 3 parts of polyethoxylated fatty alcohol, 0.5 part of polyethoxylated isomeric fatty alcohol, 3.5 parts of citric acid, 8 parts of sodium citrate, 0.15 part of polydimethylsiloxane, and distearyl ester- 1 part of hydroxyethyl-methyl-ammonium methyl sulfate, 0.6 parts of methyl-oleamide ethyl-oleic acid-imidazoline ammonium methyl sulfate, 0.3 parts of essence, 60 parts of potassium sulfate, 15 parts of potassium sulfate, press The process of producing powdered laundry detergent produces a laundry rinse booster containing methyl sulfate group quaternary ammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com